Dec . 26, 2024 08:01 Back to list

Exploring the Functionality and Applications of Diaphragm Type Pressure Gauges

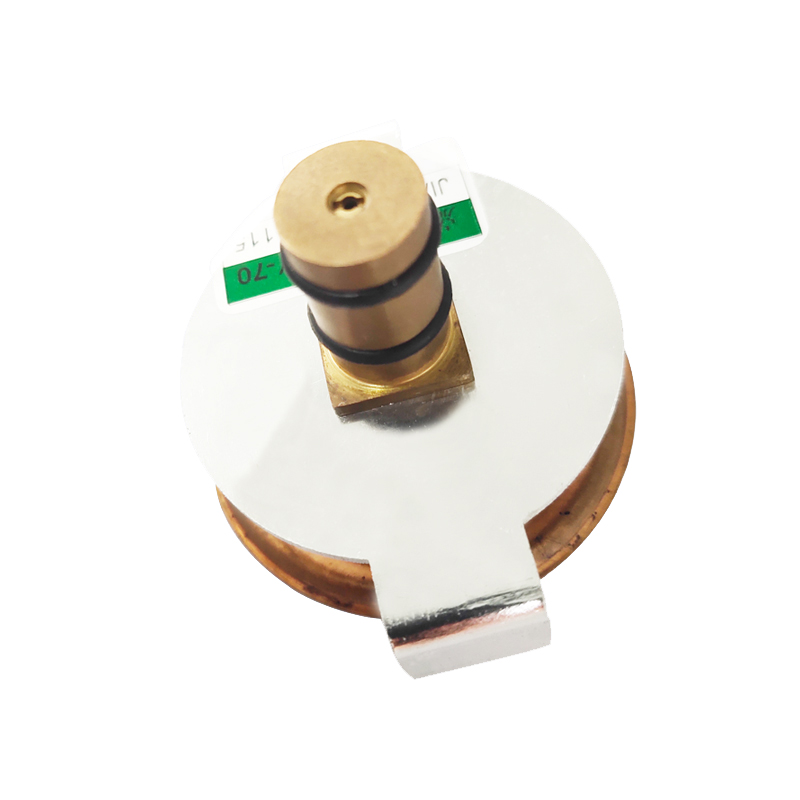

Understanding Diaphragm Type Pressure Gauges

Pressure gauges are vital instruments used across various industries to measure the pressure of gases or liquids. Among the different types of pressure gauges available, diaphragm type pressure gauges are particularly noteworthy due to their accuracy, reliability, and versatility. This article delves into the workings of diaphragm type pressure gauges, their applications, advantages, and considerations for use.

What is a Diaphragm Type Pressure Gauge?

A diaphragm type pressure gauge operates on the principle of a flexible diaphragm that deflects when subjected to pressure changes. The gauge typically consists of a sealed chamber containing a diaphragm made from materials like stainless steel, bronze, or elastomers. As pressure from a fluid or gas is applied to one side of the diaphragm, it bends or deflects, causing a movement that is translated into a pressure reading. This movement is usually connected to a pointer on a dial that indicates the pressure level.

How Does it Work?

The basic operation of a diaphragm pressure gauge involves several components

1. Diaphragm The heart of the gauge, this flexible membrane responds to pressure changes. It separates the measuring pressure from the ambient environment.

2. Transmitting Mechanism When the diaphragm moves due to pressure changes, it transmits the motion through a lever mechanism or a mechanical linkage to offer a readable format on the dial.

3. Dial The dial displays the pressure measurement. Most gauges are equipped with a scale marked in units such as bar, psi, or kPa, allowing the user to easily interpret the current pressure.

4. Seal Many diaphragm gauges are designed to be hermetically sealed to prevent contamination from external environments, which is crucial in many applications.

Applications of Diaphragm Type Pressure Gauges

Diaphragm type pressure gauges are used in a multitude of applications across various sectors

- Process Industries These gauges are particularly prevalent in chemical and petrochemical processing where corrosive substances are handled. The diaphragm's materials can be selected to withstand these harsh environments.

- Food and Beverage In food processing, maintaining proper pressure is essential to ensure quality and safety. Diaphragm gauges ensure precise pressure monitoring in these delicate operations.

- HVAC Systems These gauges are used to measure and control pressures in heating, ventilation, and air conditioning systems, helping to ensure optimal performance

.a diaphragm type pressure gauge

- Hydraulic Systems In hydraulic machinery, accurate pressure readings are crucial for maintaining system integrity and preventing failures.

Advantages of Diaphragm Type Pressure Gauges

The diaphragm type pressure gauge has several advantages that make it a preferred choice in many applications

1. High Accuracy Diaphragm gauges provide accurate and consistent pressure readings, which are essential for process control and safety.

2. Wide Range of Applications Due to their robust design and customizable materials, diaphragm gauges can be adapted for a wide range of gases and liquids, including corrosive and viscous substances.

3. Compact Design The compact nature of these gauges allows them to be installed in tight spaces without compromising performance.

4. Minimal Maintenance With fewer moving parts compared to other types of gauges, diaphragm gauges require less maintenance, resulting in lower operational costs.

5. Resistance to Pulsation Many diaphragm gauges are designed to dampen pressure fluctuations, ensuring stable readings even in applications with variable pressure.

Considerations for Use

While diaphragm type pressure gauges offer numerous benefits, there are certain considerations to keep in mind

- Selection of Materials Choosing the right material for the diaphragm and housing is crucial, especially in corrosive or extreme temperature applications.

- Calibration Like all measuring instruments, regular calibration is essential to maintain accuracy over time.

- Installation Proper installation is vital to ensure the gauge performs accurately and reliably. It should be positioned to avoid liquid accumulation and vibrations that can affect readings.

Conclusion

In conclusion, diaphragm type pressure gauges are essential tools in a wide array of industrial applications. Their accuracy, durability, and versatility make them a favored choice for monitoring and controlling pressure. By understanding their operation, advantages, and critical considerations, users can effectively implement these instruments to enhance productivity and safety in their operations. With technology continually advancing, diaphragm gauges will likely evolve, further solidifying their role in modern industrial processes.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025