Dec . 28, 2024 13:10 Back to list

differential pressure gauge manufacturer factory

Differential Pressure Gauge Manufacturers Understanding the Essentials

Differential pressure gauges are critical instruments used in various industries, including oil and gas, pharmaceuticals, food and beverage, and water treatment. These gauges measure the difference in pressure between two points in a system, providing essential data for monitoring and controlling processes. As a result, the demand for high-quality differential pressure gauges has led to the emergence of numerous manufacturers around the globe.

The Importance of Differential Pressure Gauges

In many industrial applications, maintaining optimal pressure levels is crucial to ensure safety, efficiency, and quality. Differential pressure gauges are instrumental in detecting changes in pressure that could signify system malfunctions or inefficiencies. For instance, in HVAC systems, these gauges help monitor the pressure drop across air filters and coils, thereby indicating when maintenance is required. In the pharmaceutical industry, they ensure that processes remain within specified pressure parameters, which is essential for product quality and regulatory compliance.

Key Features of Differential Pressure Gauges

Manufacturers of differential pressure gauges incorporate various features to enhance the performance and reliability of their products. Some of the essential features include

1. Accuracy High-quality differential pressure gauges offer superior accuracy, ensuring that the measurements are reliable. Accuracy is vital, especially in applications where precision is paramount, such as in laboratory settings or critical process environments.

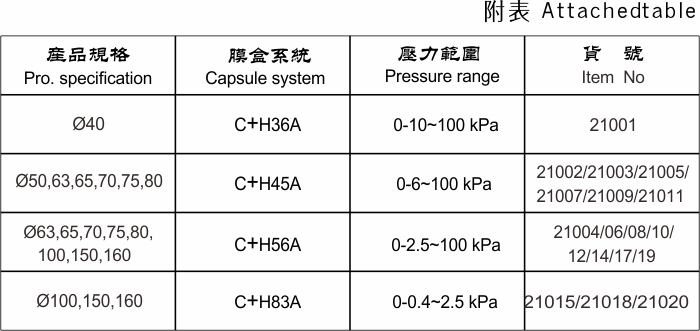

2. Range A differential pressure gauge should cover a suitable pressure range for its intended application. Manufacturers provide gauges that can measure both low and high differences in pressure to cater to a wide array of industries.

3. Material Construction Depending on the environment in which they will be used, differential pressure gauges can be constructed from various materials, including stainless steel, brass, and plastic. Manufacturers take into consideration factors like chemical compatibility, temperature extremes, and mechanical stress when designing these gauges.

4. Display Type Some differential pressure gauges come with analog displays, while others offer digital readouts. Digital gauges may include additional features like data logging and remote monitoring capabilities, which can be extremely useful for modern industrial applications.

differential pressure gauge manufacturer factory

5. Installation and Maintenance Manufacturers often design differential pressure gauges for easy installation and maintenance. Some models include features such as isolated elements or built-in isolation valves to facilitate safe and efficient servicing.

Selecting a Reliable Manufacturer

Choosing the right manufacturer for differential pressure gauges is critical to ensure that you receive a reliable and high-performing product. Here are some factors to consider during your selection process

1. Experience and Reputation Look for manufacturers with a proven track record in the industry. Companies that have been in business for several years often have the expertise and experience to provide quality products and support.

2. Certifications and Standards Reputable manufacturers adhere to international quality standards and possess relevant certifications, such as ISO 9001. These certifications indicate that the manufacturer follows strict quality control processes, ensuring that their products meet industry requirements.

3. Customer Support An excellent manufacturer will offer robust customer support, including pre-sales consultation, technical advice, and after-sales service. This support can be invaluable if you encounter any issues or require assistance with installation and calibration.

4. Customization Options Some manufacturers offer customization services to meet specific needs. If your application requires specialized features or unique measurements, a manufacturer willing to accommodate these requests can be a significant advantage.

5. Feedback and Reviews Consider customer feedback and reviews when evaluating a manufacturer. Positive testimonials indicate that the products perform well and that the manufacturer provides satisfactory customer service.

Conclusion

Differential pressure gauges are indispensable tools that play a vital role in various processes across numerous industries. As the demand for high-quality gauges increases, so does the number of manufacturers in the market. By understanding the key features of these instruments and what to look for in a reliable manufacturer, companies can make informed purchasing decisions that enhance operational efficiency, safety, and compliance in their respective industries. Investing in high-quality differential pressure gauges not only ensures accurate pressure readings but also contributes to the overall success and reliability of industrial processes.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025