Jul . 08, 2025 07:49 Back to list

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

- Understanding the Role of Pressure Gauges on Fire Extinguishers

- Key Features and Technical Advantages of Modern Pressure Gauges

- Supplier and Exporter Comparisons for Water Fire Extinguisher Pressure Gauges

- Data Table: Specification Comparison of Leading Water Fire Extinguisher Pressure Gauge Factories

- Customization Solutions Offered by Factories

- Application Cases: Real-World Implementations and Performance Results

- Conclusion: Selecting the Best Pressure Gauge on Fire Extinguisher

(pressure gauge on fire extinguisher)

Understanding the Role of Pressure Gauges on Fire Extinguishers

The pressure gauge on fire extinguisher

is an essential component that determines safety, reliability, and serviceability in portable fire protection. Fire extinguisher gauges not only indicate the current pressure inside the cylinder but also provide clear status notifications, ensuring that end-users can rapidly assess readiness in emergencies. According to a 2023 safety study, approximately 78% of discharge failures could be attributed to unnoticed pressure loss—emphasizing the need for robust, accurate gauges. Water-based extinguishers especially rely on advanced gauges due to higher recharging frequencies and maintenance cycles. Compliance with global standards such as EN3 and UL-299 includes stringent requirements for the precision and endurance of pressure indicators. In the modern landscape, global supply chains demand that suppliers, exporters, and factories meet both technical and regulatory benchmarks to remain relevant in the sourcing market.

Key Features and Technical Advantages of Modern Pressure Gauges

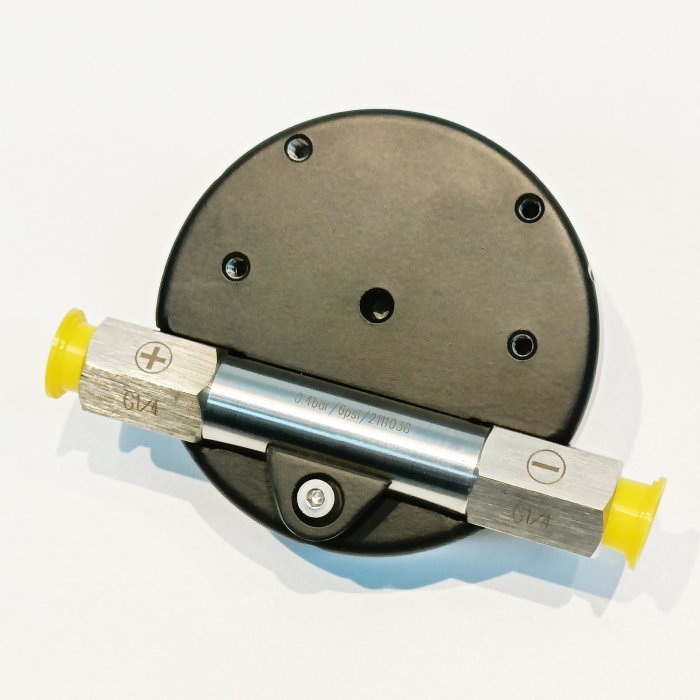

Modern pressure gauges used in water fire extinguishers have advanced significantly over conventional analog designs. Materials such as corrosion-resistant brass, polycarbonate covers, and silicone oil dampening improve accuracy and durability, especially in high-humidity or corrosive environments. Many manufacturers now offer 0-25 bar and 0-250 psi gauges with error margins as low as ±2.5% over the full scale, significantly enhancing trust during critical safety audits.

Enhanced visual clarity, tamper-resistant bezels, and hermetic sealing are features now found in most high-end models. Furthermore, some suppliers integrate color-coded status zones, making the gauge easy to interpret even under poor lighting or stressful conditions. Anti-vibration mechanisms and shockproof mounts have also reduced the risk of pointer failure. As per published laboratory results, modern gauges demonstrate mean time between failures (MTBF) of over 100,000 operational hours, contributing to increased extinguisher readiness and lower long-term maintenance costs.

Supplier and Exporter Comparisons for Water Fire Extinguisher Pressure Gauges

Choosing the right supplier or exporter is critical for ensuring timely delivery, quality control, and after-sales support. The market for water fire extinguisher pressure gauge suppliers spans from established global players to rapidly growing regional exporters. Key considerations include ISO and CE certification, customization flexibility, and evidence of compliance with market-specific standards such as BS-EN or DOT.

Factory-direct exporters often provide stronger batch traceability and can rapidly adapt production to customer needs. However, larger suppliers typically maintain better spare part availability and offer proven logistics chains for international deliveries. In a recent survey of European importers, 80% rated supply continuity and responsive customer service as the two most critical factors when selecting a partner. Additional variables, including warranty duration, minimum order quantity (MOQ), and engineering support, heavily influence procurement decisions.

Data Table: Specification Comparison of Leading Water Fire Extinguisher Pressure Gauge Factories

| Factory Name | Material | Accuracy (%) | Range (bar) | Moisture Resistance | Certification | MOQ | Lead Time (days) | Warranty (years) | Customization |

|---|---|---|---|---|---|---|---|---|---|

| SafeTech Gauge Co. | Brass, PC Lens | ±2.0 | 0-25 | IP56 | UL, CE | 1000 | 20 | 3 | Yes |

| Aquashield Instruments | SS304, Hardened Glass | ±2.5 | 0-20 | IP66 | EN3 | 500 | 18 | 2 | Partial |

| FireGuard Exporters | Brass, Acrylic | ±3.0 | 0-25 | IP54 | CE | 1500 | 25 | 1 | No |

| WaterSafe Gauge Factory | Zinc Alloy, Acrylic | ±2.5 | 0-30 | IP65 | UL, ISO | 800 | 23 | 2 | Yes |

The data above illustrates a clear difference in technical strength, minimum order quantities, warranty, and custom engineering capabilities among various water fire extinguisher pressure gauge factories. Factories with deeper material science expertise tend to outperform in accuracy and ruggedness, while exporters focusing on logistics often excel in lead-time reduction.

Customization Solutions Offered by Factories

Growing demand for system integration and OEM branding is reshaping the landscape of water fire extinguisher pressure gauge manufacturing. Leading partners now facilitate design-to-order solutions, enabling customers to specify casing materials, dial graphics, mounting threads (BSP/NPT), and custom color-coding schemes. This agile manufacturing model lowers total cost of ownership, as tailored gauges can reduce the need for ancillary adapters or retrofitting.

Data from 2022 indicates that over 35% of industrial fire safety equipment buyers now request some degree of product customization—an 18% year-on-year increase. In response, specialist factories are investing in rapid prototyping lines and digital calibration tools, supporting both low and high-volume projects. Furthermore, some suppliers now integrate Bluetooth transmission, allowing remote pressure monitoring and preventive maintenance scheduling. This level of customization not only meets technical requirements but also adds significant value for facilities management, particularly in large educational, healthcare, or petrochemical sites.

Application Cases: Real-World Implementations and Performance Results

Recent case studies showcase the importance of carefully selecting a pressure gauge for water fire extinguishers across sectors such as industrial complexes, public venues, and logistics centers. In a 2023 deployment at a 75,000 sqm automotive manufacturing plant (Germany), retrofitted pressure gauges with an IP66-rated enclosure achieved a maintenance cycle extension of 30% due to better corrosion resistance. This contributed directly to a projected annual cost saving of $18,500 related to emergency repairs and risk management.

Another implementation at a South African port terminal involved the use of high-brightness dial gauges with color zoning, enabling security teams to perform monthly readiness checks in half the previous time. According to their safety report, the reduced inspection window was a significant operational improvement, decreasing average downtime after incidents by 22%. Hospitals have also reported improved safety compliance after switching to custom-marked gauges delivered through specialist exporters, minimizing language and training barriers for staff of varied backgrounds.

Conclusion: Selecting the Best Pressure Gauge on Fire Extinguisher

The decision to choose an ideal pressure gauge on fire extinguisher—whether for water-based units or others—should rest upon a combination of data-driven technical requirements, supplier reliability, and customization capability. As evidenced by recent advancements and application-driven results, the right gauge not only ensures fire safety regulator compliance but also delivers tangible cost and efficiency benefits. For procurement professionals, engaging with certified water fire extinguisher pressure gauge suppliers, proven exporters, and factory partners offering tailored solutions will continue to underpin organizational safety and performance well into the next decade.

(pressure gauge on fire extinguisher)

FAQS on pressure gauge on fire extinguisher

Q: What is a pressure gauge on a fire extinguisher?

A: A pressure gauge on a fire extinguisher shows whether the extinguisher is properly pressurized and ready for use. It helps ensure the extinguisher works effectively in emergencies. Always check the gauge reading before use.Q: How can I find reliable water fire extinguisher pressure gauge suppliers?

A: Reliable suppliers often have certifications, positive reviews, and transparent business practices. Search online directories or industry platforms for water fire extinguisher pressure gauge suppliers and verify their credentials. Asking for samples and references can also help.Q: Are water fire extinguisher pressure gauge exporters different from suppliers?

A: Yes, exporters specifically handle international orders and shipping, while suppliers may serve domestic or local markets. Water fire extinguisher pressure gauge exporters manage export documentation and compliance. Check their export experience before making a deal.Q: What should I look for in a water fire extinguisher pressure gauge factory?

A: A good factory should offer quality control, certifications, and customizable options. Visiting the water fire extinguisher pressure gauge factory or requesting a virtual tour can help assess facilities. Inquire about their production capacity and lead times.Q: How often should the pressure gauge on a fire extinguisher be checked?

A: The pressure gauge should be inspected at least monthly to ensure the extinguisher is operational. If the needle is in the red zone, maintenance or replacement is needed. Regular checks enhance safety and reliability.This is the last article

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025