Aug . 12, 2024 07:56 Back to list

Optimal Capillary Diaphragm Seals for Accurate Pressure Gauge Performance in Critical Applications

The Best Capillary Diaphragm Seal Pressure Gauge An In-Depth Overview

In the realm of industrial instrumentation, pressure measurement is paramount. One of the most reliable devices used for this purpose is the capillary diaphragm seal pressure gauge. This type of gauge stands out in its ability to accurately measure pressure in hostile environments, making it a preferred choice for many applications, including chemical processing, oil and gas, and wastewater management.

Understanding the Basics

A capillary diaphragm seal pressure gauge consists of two main components the diaphragm seal and the pressure gauge. The diaphragm seal is designed to isolate the pressure-sensitive element of the gauge from the medium being measured. This is particularly important when dealing with corrosive, viscous, or high-temperature fluids. The diaphragm itself flexes in response to pressure changes, transmitting that motion to the pressure gauge via a capillary tube.

The capillary tube allows for the transfer of pressure signals over a distance, making it ideal for applications where the pressure source is located in areas that may be inaccessible or hazardous. This design offers significant advantages in protecting the gauge mechanism and prolonging its lifespan.

Advantages of Capillary Diaphragm Seal Pressure Gauges

1. Corrosion Resistance One of the defining benefits of using a diaphragm seal is its ability to withstand corrosive substances. With various materials available, such as stainless steel or exotic alloys, these gauges can be tailored to meet the chemical compatibility needs of specific applications.

2. Reduced Maintenance The diaphragm seal minimizes fluid exposure to the gauge's internal components, significantly reducing the risk of clogging or damage. This feature translates to lower maintenance requirements and minimized downtime, which is essential in continuous operation environments.

3. Temperature Compensation Many industries operate under fluctuating temperature conditions that can affect pressure readings. Capillary diaphragm seal pressure gauges can be equipped with thermal compensation mechanisms that help maintain accurate readings, ensuring reliable performance in varying thermal environments.

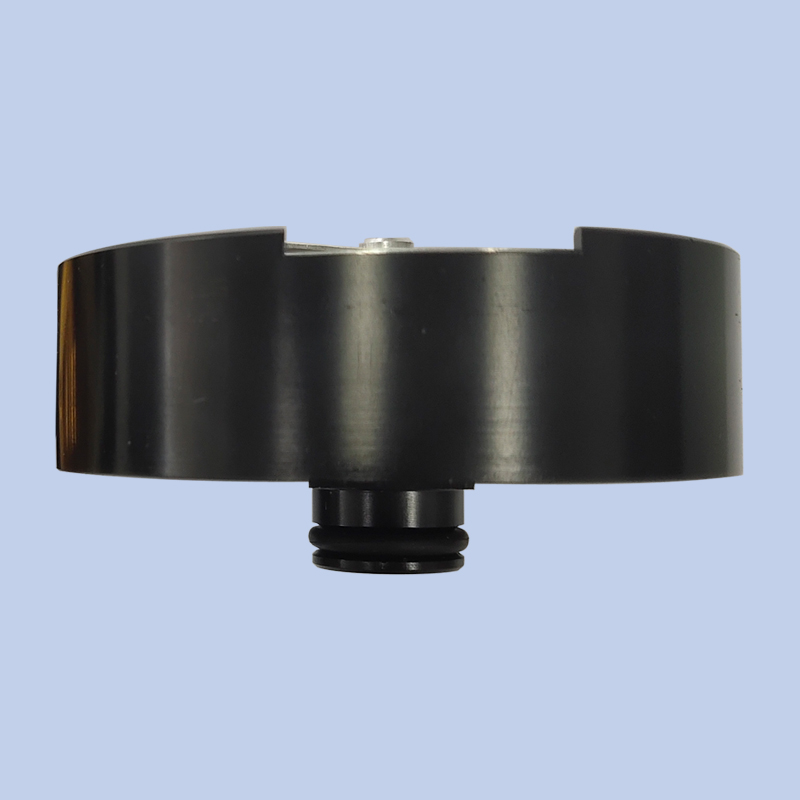

best capillary diaphragm seal pressure gauge

4. Versatility These gauges are incredibly versatile and can be used for both liquid and gas applications. Their design allows for customization, making them suitable for a wide range of industrial needs.

Choosing the Right Gauge

When selecting a capillary diaphragm seal pressure gauge, several factors must be considered

- Material Selection Ensure that the selected diaphragm material is compatible with the media it will encounter. Chemical analysis may be necessary to assess compatibility correctly.

- Pressure Range Identify the maximum and minimum pressure levels of the application to choose a gauge with suitable calibration.

- Temperature Limits Consider the maximum and minimum operating temperatures of the environment, as this will further influence material choice and gauge performance.

- Response Time In dynamic pressure applications, it’s vital to select a gauge that offers an appropriate response time to ensure accurate readings.

Conclusion

The capillary diaphragm seal pressure gauge is an invaluable tool in industrial settings where environment and media can challenge conventional measurement devices. By providing robust solutions to issues like corrosion, temperature variance, and maintenance, these gauges offer a high degree of reliability and accuracy. For industries where operational efficiency and safety are paramount, investing in the best capillary diaphragm seal pressure gauge is a decision that can lead to improved productivity and peace of mind. As technological advancements continue to evolve, the performance and application scope of these pressure gauges are likely to expand even further, solidifying their place as a critical component in industrial measurement systems.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025