Dec . 16, 2024 02:45 Back to list

Differential Pressure Gauges for Accurate Measurement in Gammon Applications

Understanding Gammon Differential Pressure Gauge Products

In the world of industrial measurement and control, accuracy and reliability are paramount. One of the essential tools used for monitoring various processes is the differential pressure gauge. Among the leading manufacturers in this field, Gammon stands out by offering a broad range of high-quality differential pressure gauge products that cater to various industries and applications.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points in a system. This is crucial for applications involving fluid flow, ventilation, filtration, and other processes where maintaining specific pressure levels is essential. By checking the pressure differences, operators can gain insights into the performance of equipment, ensuring that systems are functioning optimally and safely.

The Role of Gammon in Differential Pressure Measurement

Gammon Instrument Company, founded in the early 20th century, has established a reputation for precision and innovation in pressure measurements. Their differential pressure gauge products are designed to provide accurate readings in various conditions, making them a preferred choice for many industries, including HVAC, water treatment, pharmaceuticals, and oil and gas.

Product Features and Advantages

1. High Accuracy and Reliability Gammon's differential pressure gauges are engineered with precision components that ensure minimal error and high reliability. This accuracy is critical in applications where small pressure differentials can significantly impact process efficiency and safety.

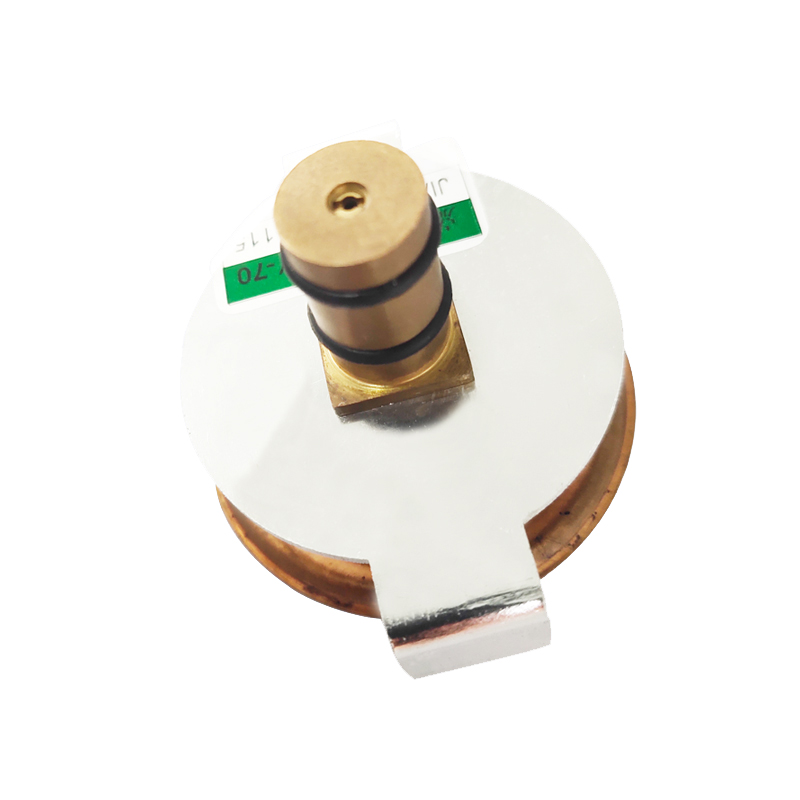

gammon differential pressure gauge products

2. Robust Construction Many of Gammon's differential pressure gauges feature durable materials that withstand harsh environments. This includes options such as stainless steel and brass, which resist corrosion and wear, extending the instrument's lifespan under demanding conditions.

3. User-Friendly Design The gauges are designed with readability in mind. Most models feature large, clear dials with easy-to-read markings, allowing operators to take quick measurements without fuss. Some models even offer LED displays for enhanced visibility in low-light conditions.

4. Versatility Gammon's differential pressure gauges are available in various ranges and styles, catering to a wide array of applications. Whether it’s for monitoring the pressure in HVAC systems or ensuring proper filtration in water treatment plants, there is likely a Gammon gauge suited for the task.

5. Customization Options Understanding that different applications may have unique requirements, Gammon offers customization options for its differential pressure gauges. Customers can select specific ranges, materials, and mounting options, ensuring that the gauge integrates seamlessly into their existing systems.

Applications Across Industries

The versatility of Gammon's differential pressure gauges makes them suitable for numerous applications. In the HVAC industry, they monitor airflow across filters and ducts to ensure efficient operation. In water treatment facilities, they are crucial for monitoring pressure drop across filtration systems, signaling when maintenance is needed. Furthermore, in the pharmaceutical sector, they help ensure that sterilization processes maintain the right conditions.

Conclusion

In conclusion, Gammon differential pressure gauge products exemplify quality and reliability, making them an invaluable asset across various industries. Their commitment to precision measurement and user-centered design ensures that customers can rely on their gauges to monitor crucial processes effectively. By investing in Gammon's differential pressure gauges, operators not only enhance operational efficiency but also contribute to the safety and longevity of their systems. As industries continue to evolve, the demand for accurate pressure measurement will remain, and Gammon is well-positioned to meet this need with innovative solutions.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025