Dec . 25, 2024 20:32 Back to list

Differential Pressure Gauge 733 Manufacturing Insights and Overview

Understanding the WIKA Differential Pressure Gauge Model 733 A Comprehensive Overview

Differential pressure gauges are vital instruments in a myriad of industrial and laboratory applications. Among the myriad of options available in the market, the WIKA Differential Pressure Gauge Model 733 stands out for its precision, reliability, and versatile application. This article explores the features, construction, and applications of this particular model, emphasizing why it has become a trusted choice for many industries.

Features and Technical Specifications

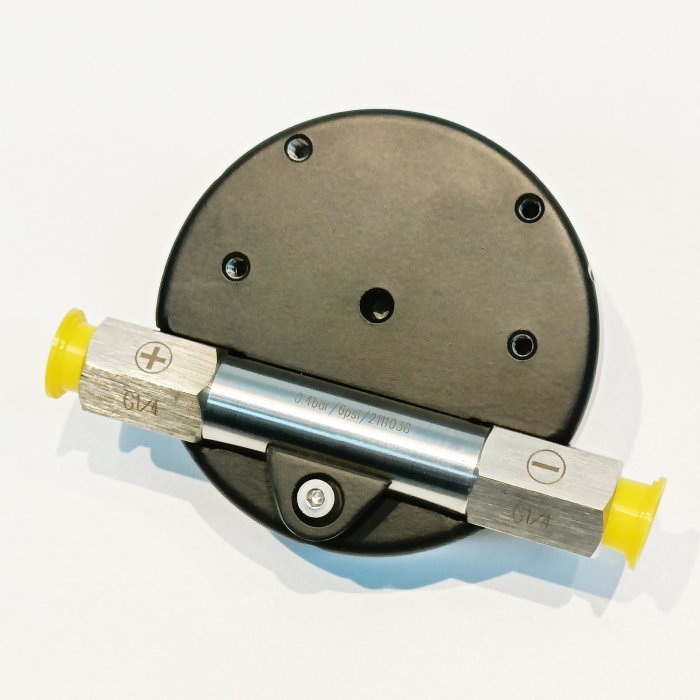

The WIKA Model 733 is a mechanical differential pressure gauge designed to measure the pressure difference between two points in a system. Its primary features include a robust construction, an easy-to-read dial, and a variety of pressure ranges, which make it suitable for different operational environments. The gauge typically has a stainless steel housing, ensuring durability and resistance to corrosion, making it ideal for harsh industrial settings.

The Model 733's measurement range is quite extensive, catering to both low and high differential pressure measurements. Standard ranges often extend from 0 to 0.6 bar up to 0 to 40 bar, allowing users to select the correct gauge based on their specific needs. Additionally, the gauge offers precision calibration, often achieved within a ±1.6% accuracy class, providing reliable and consistent readings.

One significant advantage of the WIKA 733 is its mechanical design, which eliminates the need for an external power source. This makes it particularly beneficial in remote locations or areas where electrical access is limited. Users can depend on the gauge for continuous monitoring without the dilemmas posed by battery or power failures.

Construction and Design

wika differential pressure gauge 733 factories

The differential pressure gauge's construction is paramount in ensuring its operation and longevity. The WIKA 733 features a diaphragm measuring element, primarily made from stainless steel or other compatible materials, allowing it to withstand different media pressures and chemical processes. The diaphragm's ability to flex in response to pressure changes makes it an effective sensor for gauging pressure differences.

The gauge's face displays a clear, easy-to-read dial, typically with a white background and black markings for optimal visibility. Many models include color-coded segments that provide quick visual indicators of operating ranges, alerting operators to any potential issues at a glance. This ergonomic design is particularly beneficial in environments with poor visibility or for operators who need to make quick decisions based on gauge readings.

Applications

The versatility of the WIKA 733 differential pressure gauge makes it suitable for various applications, particularly in the fields of HVAC (Heating, Ventilation, and Air Conditioning), water treatment, and process technology. In HVAC systems, for instance, the gauge is commonly used to monitor filter conditions, ensuring that systems operate efficiently and maintain optimal air quality.

In the realm of water treatment, differential pressure gauges are integral in monitoring pressure drops across filters and membranes. This is crucial for maintaining purification systems' effectiveness, ensuring that water remains safe and clean for consumption. Additionally, the WIKA 733 is frequently employed in various industrial processes such as chemical production, pharmaceuticals, and food and beverage manufacturing, where pressure monitoring plays a critical role in maintaining product quality and safety.

Conclusion

The WIKA Differential Pressure Gauge Model 733 exemplifies what modern engineering has achieved in terms of precision, reliability, and user-friendly design. With its robust construction, extensive measurement range, and versatile applications, it has become a preferred choice in various industries. Whether it is monitoring HVAC systems or ensuring the efficiency of water treatment facilities, the Model 733 guarantees accurate measurements and helps maintain operational efficiency. As industries continue to evolve, the demand for reliable and effective monitoring solutions will only grow, and the WIKA 733 is well-positioned to meet these challenges head-on.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025