Dec . 25, 2024 21:11 Back to list

Innovative Flanged Diaphragm Seal Pressure Gauge for Enhanced Measurement Accuracy

Understanding the Famous Flanged Diaphragm Seal Pressure Gauge

In the field of industrial instrumentation, the flanged diaphragm seal pressure gauge plays a critical role in ensuring accurate and reliable pressure measurements. This device is particularly favored in applications where the pressure medium may be corrosive, viscous, or otherwise incompatible with standard pressure gauges. By utilizing a diaphragm seal, this instrument ensures that sensitive components are protected, thus extending the life of the gauge and maintaining measurement integrity.

What is a Flanged Diaphragm Seal Pressure Gauge?

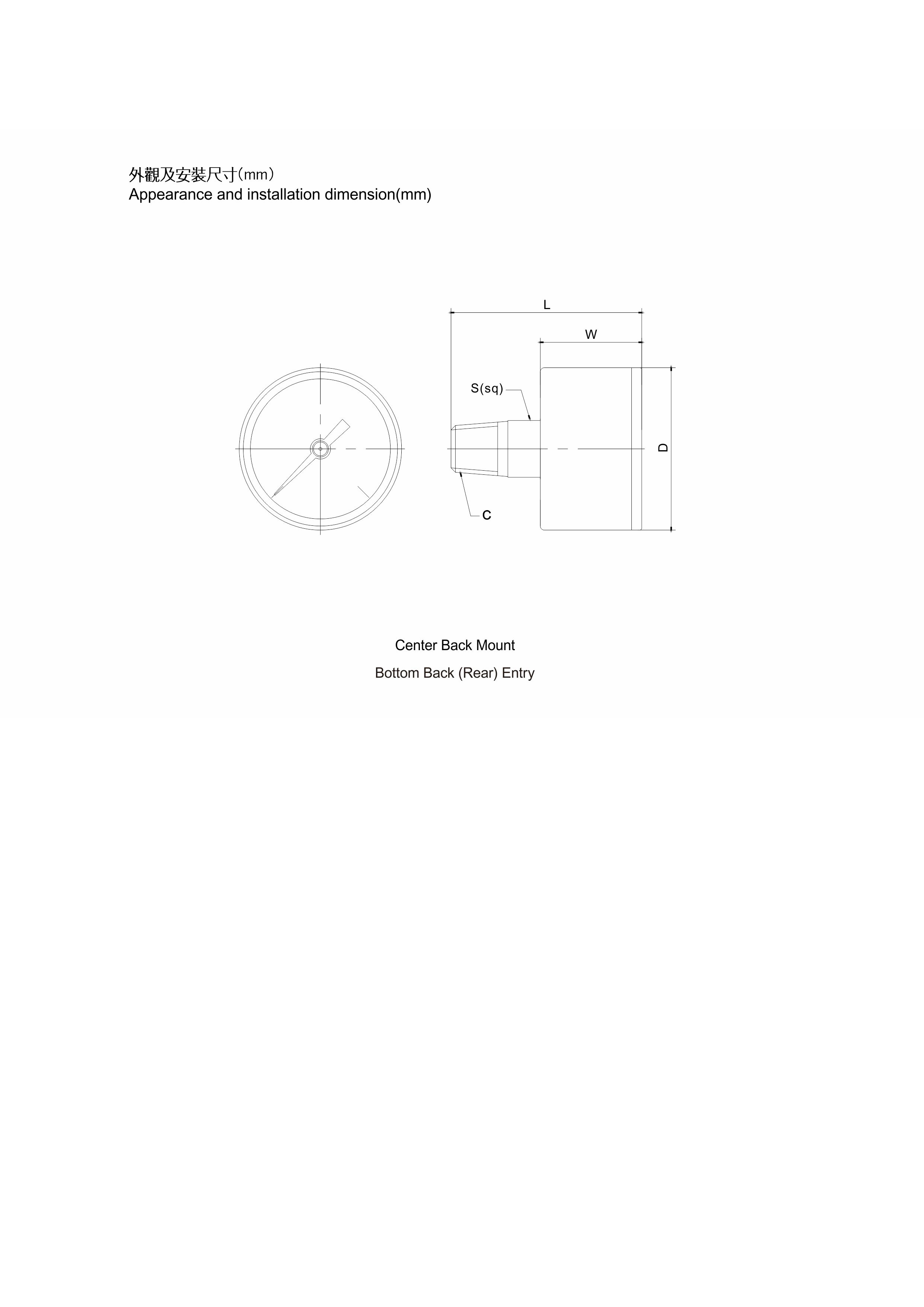

A flanged diaphragm seal pressure gauge consists of three main components the diaphragm seal, the pressure gauge, and a flange for mounting. The diaphragm serves as a barrier between the measurement element and the process fluid, effectively isolating the gauge from any harsh conditions. The diaphragm flexes in response to pressure changes, transmitting the resultant mechanical movement to the gauge mechanism, which then indicates the pressure reading.

The flange provides a secure connection to the piping system and can accommodate various pipe sizes, ensuring versatility in installation. This design not only facilitates easy installation but also enables the gauge to be removed for maintenance without interrupting the flow of the process medium.

Applications and Advantages

Flanged diaphragm seal pressure gauges are widely used across various industries, including oil and gas, chemical processing, pharmaceuticals, and food and beverage. Their ability to handle extreme conditions—such as high temperatures, pressures, and corrosive environments—makes them invaluable in many industrial processes.

One of the key advantages of using a diaphragm seal is its capacity to isolate the gauge from the process fluid. This isolation is crucial when dealing with corrosive materials that could damage sensitive internal components, such as the sensing element in a standard pressure gauge. Additionally, diaphragm seals can accommodate thick or viscous fluids that may clog traditional gauges, thus ensuring ongoing accuracy and reliability.

famous flanged diaphragm seal pressure gauge

Another significant benefit is the reduction of dead leg effects, which are common in traditional piping systems. Dead legs can cause stagnation and buildup of material, leading to inaccurate readings. With the diaphragm design, the gauge can provide a true reflection of the process fluid pressure, even in challenging scenarios.

Installation and Maintenance

Proper installation and maintenance of flanged diaphragm seal pressure gauges are essential to ensure their effective operation. During installation, it is critical to ensure that the flange is correctly aligned with the piping system and that all seals are tight to prevent leaks. Regular inspections should be conducted to check for signs of wear, buildup, or corrosion around the diaphragm and connections.

Maintenance of these gauges is relatively straightforward. In most cases, it involves routine checking of the pressure readings against a standard to ensure accuracy. If discrepancies arise, recalibration or replacement of the diaphragm seal may be necessary. Given their design, diaphragm seal pressure gauges often have a longer lifespan compared to standard gauges, provided they are maintained properly.

Conclusion

The flanged diaphragm seal pressure gauge represents a vital tool in modern industrial applications. Its unmatched ability to withstand harsh environments while providing accurate pressure readings makes it indispensable across various sectors. Whether in a chemical plant, oil refinery, or food processing facility, these gauges help maintain operational efficiency and safety.

In summary, understanding the functional principles, applications, and maintenance of the flanged diaphragm seal pressure gauge enables engineers and operators to utilize this innovative technology effectively. As industries continue to evolve, the importance of reliable instrumentation will only increase, solidifying the role of diaphragm seal pressure gauges in ensuring operational excellence.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025