Oct . 21, 2024 05:46 Back to list

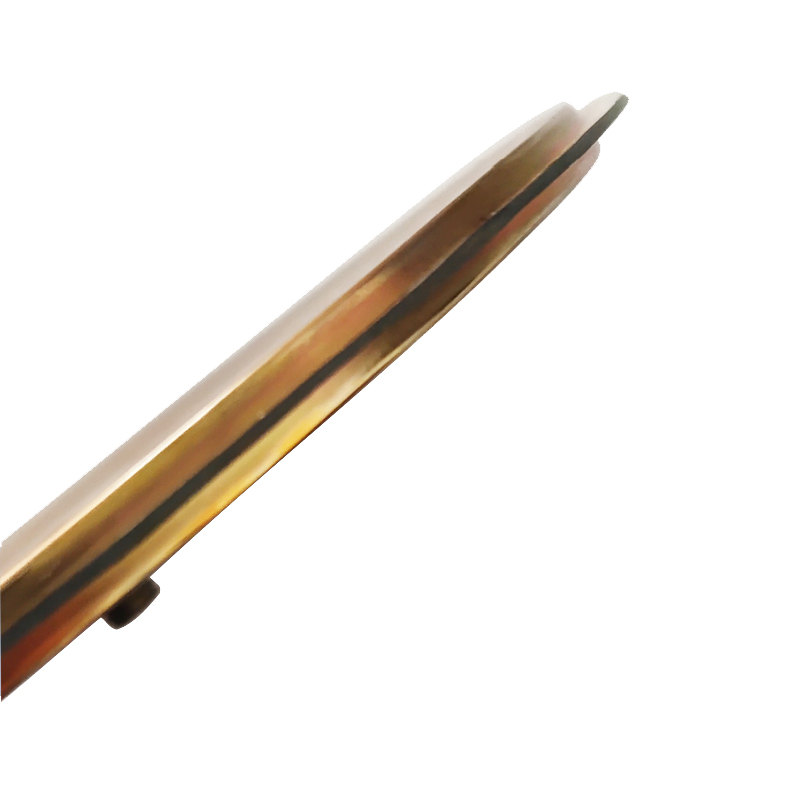

High-Performance Differential Pressure Gauge Assembly for Precision Measurement Applications

High-Quality Differential Pressure Gauge Assembly A Comprehensive Overview

In the realm of industrial processes, precise measurement of pressure plays a crucial role in ensuring operational efficiency and safety. Among the various instruments used for this purpose, differential pressure gauges stand out due to their ability to measure the difference in pressure between two points in a system. This article delves into the significance of high-quality differential pressure gauge assemblies, their construction, operating principles, applications, and the crucial factors to consider when selecting them for various industrial applications.

Understanding Differential Pressure Gauges

A differential pressure gauge is an instrument specifically designed to measure the pressure difference between two points. The differential pressure can indicate flow rates, filter conditions, and liquid levels, making it essential for monitoring systems like HVAC, filtration, and fluid transportation.

Components of a Differential Pressure Gauge Assembly

A typical differential pressure gauge assembly consists of several critical components

1. Sensing Elements These can be diaphragm, capsule, or piezoresistive types. They convert pressure changes into mechanical or electrical signals. 2. Indicator This component visually represents the pressure difference, typically through a dial or digital display.

3. Connection Ports Two ports allow for the connection of the gauge to the pressure points of interest.

4. Isolating Valves These are used to isolate the gauge during maintenance or when the system is depressurized, ensuring safety.

5. Mounting Accessories These ensure the gauge is securely installed in the required position for optimal performance.

6. Transmitter (optional) In some assemblies, a transmitter is integrated to convert mechanical signals into electronic signals for remote monitoring.

Operating Principles

Differential pressure gauges operate on the principle of pressure differentials. When fluid flows through a system, it creates differing pressures at various points. The gauge measures this difference, yielding valuable insights into flow rates or conditions of the monitored system.

As the pressure changes, it affects the sensing element, which in turn leads to a movement that translates into a reading on the gauge. For instance, a diaphragm-type gauge bends in response to pressure changes, moving a pointer on the dial for a visual representation or sending an electronic signal to a monitoring system.

high quality differential pressure gauge assembly

Applications of Differential Pressure Gauge Assemblies

The versatility of high-quality differential pressure gauges makes them suitable for diverse applications. Common industries utilizing these gauges include

- Water Treatment Monitoring pressure across filtration systems to ensure optimal operation. - HVAC Systems Ensuring efficient airflow and system integrity by measuring pressure in ducts and equipment. - Oil and Gas Monitoring pressure drops across pipelines to detect leaks or blockages. - Pharmaceuticals Ensuring clean room environments by measuring the pressure across filters and controlling contamination.

Selecting High-Quality Differential Pressure Gauge Assemblies

When selecting a differential pressure gauge assembly, several factors should be considered to ensure optimal performance

1. Accuracy Look for gauges with high accuracy ratings, typically expressed as a percentage of full scale. High precision is crucial in critical applications.

2. Material Compatibility Ensure that the materials used in the gauge assembly are compatible with the fluids being measured to prevent corrosion and deterioration.

3. Range The gauge should be selected based on the expected pressure range to avoid damage and ensure accurate readings.

4. Calibration and Certification High-quality assemblies should come with calibration certificates demonstrating their accuracy and reliability.

5. Environmental Considerations Assess the environmental conditions (temperature, humidity, and potential for mechanical stress) in which the gauge will operate.

6. Maintenance Requirements Choose assemblies that are easy to maintain and service, as this will enhance their longevity and reliability.

Conclusion

A high-quality differential pressure gauge assembly is an indispensable tool in many industrial processes, aiding in the accurate measurement of pressure differences that impact system efficiency and safety. By understanding their construction, operation, applications, and selection criteria, industries can ensure they choose the most suitable instruments to meet their operational needs, ultimately leading to improved productivity and reliability. Whether monitoring fluid transport, air flow, or filtration systems, investing in quality differential pressure gauges pays dividends through enhanced performance and reduced risks.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025