Oct . 21, 2024 06:18 Back to list

OEM Diaphragm Pressure Gauge for Accurate Measurement and Durable Performance

Understanding OEM Pressure Gauges with Diaphragm Technology

In the realm of industrial measurement and control, pressure gauges play a pivotal role in ensuring the safe and efficient operation of various systems. Among the diverse types of pressure measurement devices, OEM (Original Equipment Manufacturer) pressure gauges equipped with diaphragm technology have gained popularity due to their reliability, versatility, and precision. This article delves into the key features, advantages, and applications of OEM pressure gauges with diaphragm mechanisms.

What is an OEM Pressure Gauge?

OEM pressure gauges are specially designed instruments that are standard or custom-built for integration into other equipment or systems. They are often produced by manufacturers who supply their products to other companies that incorporate these gauges into their machinery or products. Unlike off-the-shelf gauges, OEM pressure gauges can be tailored to meet specific requirements, including size, scale, and mounting options.

The Role of Diaphragm Technology

Diaphragm pressure gauges utilize a flexible diaphragm, which is a thin membrane that responds to pressure changes. When pressure is applied, the diaphragm deflects, causing a change in shape that is directly proportional to the amount of pressure exerted. This deflection is then translated into a readable value via mechanical or electronic means.

The diaphragm is typically made from materials such as stainless steel, silicone, or other elastomers, depending on the application's demands and the nature of the fluid being measured. This construction not only enhances the gauge's performance but also ensures its longevity and accuracy.

Advantages of Diaphragm Pressure Gauges

1. High Sensitivity and Accuracy Diaphragm pressure gauges are known for their responsiveness to pressure changes. They can measure low-pressure levels accurately, making them suitable for applications that require high precision.

2. Corrosion and Contamination Resistance Many diaphragm gauges are designed to handle corrosive materials by using specialized materials for the diaphragm. This feature is crucial for industries such as chemical processing, where fluids can be highly reactive or damaging.

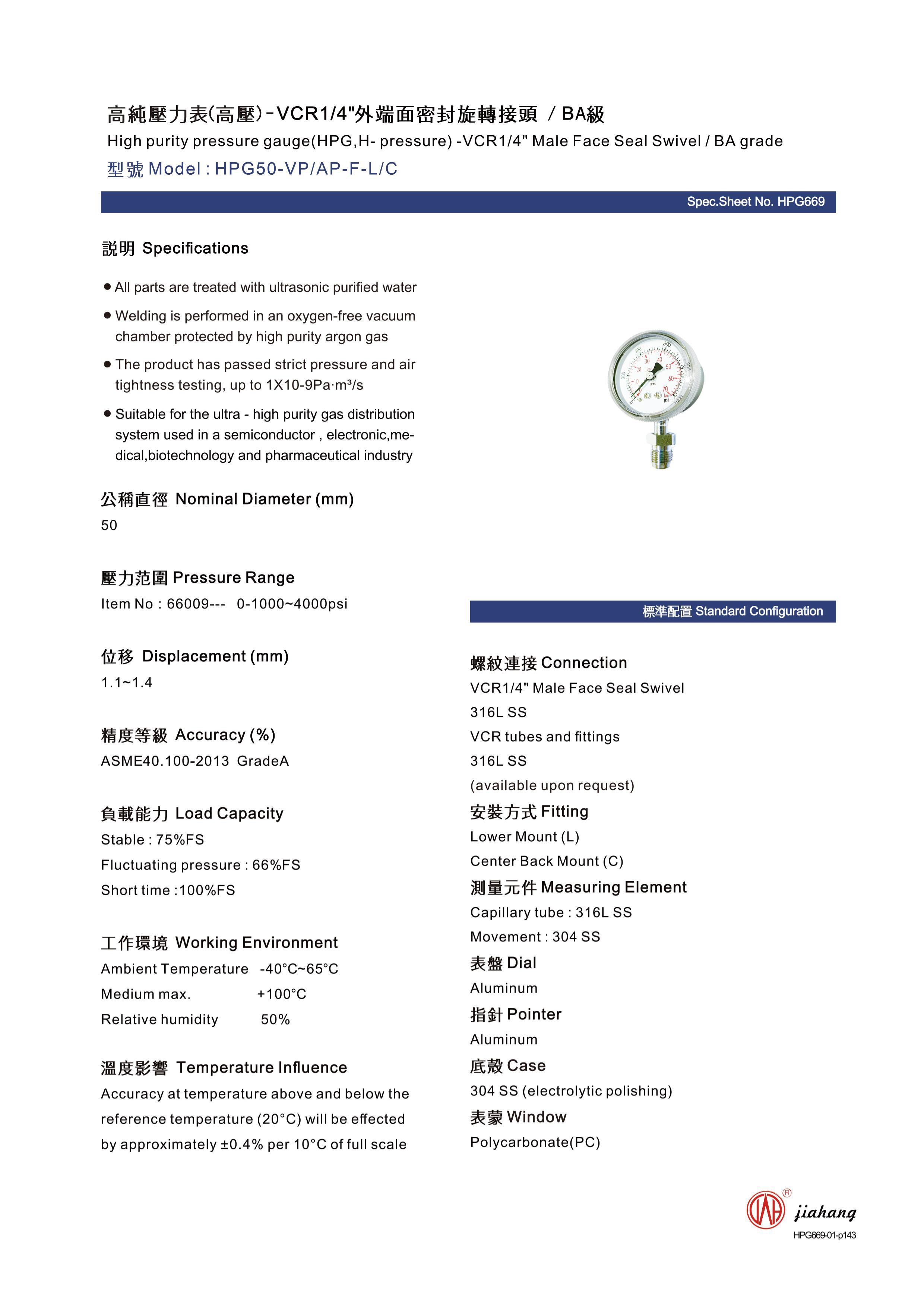

oem pressure gauge with diaphragm

3. Suitable for Pulsating Pressures The flexible nature of the diaphragm allows it to withstand pulsating pressures without damage. This resilience makes diaphragm gauges ideal for applications where pressure fluctuations are common.

5. Simple Maintenance These gauges generally require less maintenance compared to traditional Bourdon tube gauges because they are less likely to suffer from mechanical wear due to fewer moving parts.

Applications of OEM Diaphragm Pressure Gauges

OEM pressure gauges with diaphragm technology are employed across a wide array of industries and applications

- Hydraulics and Pneumatics Used to monitor fluid pressures and pneumatic systems, ensuring optimal performance and safety. - Food and Beverage In processes where hygiene is critical, diaphragm gauges made of stainless steel ensure contamination-free measurements. - Oil and Gas These gauges handle high pressures encountered in extraction and refining processes while resisting corrosive environments.

- Pharmaceuticals Maintaining precise pressure levels is vital during drug formulation and packaging operations.

- HVAC Systems Monitoring pressures in heating, ventilation, and air conditioning systems helps in maintaining efficiency and safety.

Conclusion

OEM pressure gauges with diaphragm technology offer a robust solution for a wide range of pressure measurement tasks across various industrial sectors. With their high sensitivity, durability, and versatility, these gauges ensure accurate readings, even in challenging environments. As industries continue to advance and the demand for reliable pressure measurement increases, diaphragm pressure gauges will remain a pivotal component in achieving optimal operational efficiency and safety. Understanding their functionality and applications can help companies select the right gauges for their specific needs, thereby enhancing overall productivity and performance.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025