Oct . 14, 2024 04:15 Back to list

Pressure Gauge with Diaphragm Seal Technology for Enhanced Measurement Accuracy

Understanding Diaphragm Seal Pressure Gauges A WIKA Perspective

Pressure measurement is a vital aspect in various industries, ensuring the safety, efficiency, and reliability of operations. One innovative solution designed to enhance pressure measurement accuracy and protect instrumentation from harsh environments is the diaphragm seal pressure gauge. This article delves into the functioning, advantages, and applications of diaphragm seal pressure gauges, particularly focusing on the offerings from WIKA, a leading manufacturer in the field.

What is a Diaphragm Seal Pressure Gauge?

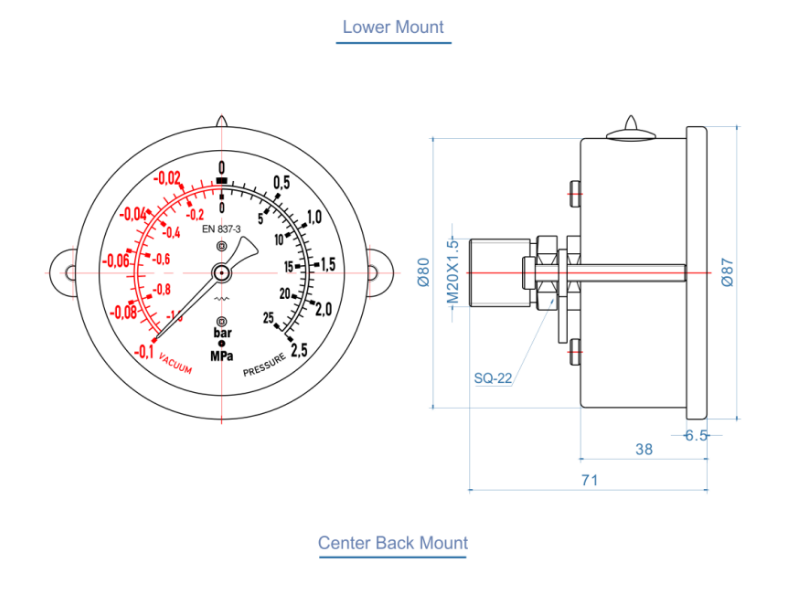

A diaphragm seal pressure gauge is a specialized instrument that measures the pressure of fluids and gases while protecting the measurement element from corrosive or viscous media. It consists of a pressure gauge connected to a flexible diaphragm, which isolates the gauge from the process media. When pressure is applied, the diaphragm deflects, transmitting the pressure to the gauge through a filling fluid, which can be oil or another suitable medium. This design prevents direct contact between the gauge mechanism and the process fluid, ensuring accurate readings and extending the life of the gauge.

Key Features

WIKA's diaphragm seals are engineered with precision to accommodate various industrial needs. Some key features include

1. Material Selection WIKA offers diaphragm seals made from a variety of materials, including stainless steel, Hastelloy, and fluoropolymer coatings, providing excellent resistance against corrosion and abrasion. This adaptability ensures that the gauges can be used in diverse environments, from chemical processing to food and beverage applications.

2. Wide Range of Measurement These gauges can measure pressures across a wide range, catering to both low and high-pressure applications. This versatility makes them suitable for nearly every industry, including oil and gas, pharmaceuticals, and HVAC.

3. Filling Fluids WIKA provides options for different filling fluids to enhance performance and compatibility with the media being measured. The choice of filling fluid is crucial as it can affect the response time and accuracy of the gauge.

4. Customizable Designs WIKA understands that every application has unique requirements. As such, they offer customized diaphragm seals that can be tailored to fit specific process conditions, including size, pressure range, and material compatibility.

diaphragm seal pressure gauge wika

Advantages of Diaphragm Seal Pressure Gauges

1. Protection Against Contamination The primary advantage of using diaphragm seals is the protection they provide against the contamination of the measurement mechanism. This is crucial in applications where process media can be aggressive or contain particulates that could damage traditional pressure gauges.

2. Improved Accuracy Due to their design, diaphragm seals help improve measurement accuracy. They mitigate issues like clogging and wear that often plague conventional gauges, leading to more reliable data over time.

3. Longevity By protecting the gauge from harsh media, diaphragm seal pressure gauges typically enjoy a longer lifespan compared to traditional gauges. This reduces maintenance costs and downtime in critical processes.

4. Versatile Applications Their ability to handle a wide variety of media, including corrosive chemicals and viscous fluids, means that diaphragm seal gauges are applicable in many industrial sectors.

Applications

Diaphragm seal pressure gauges find applications in various fields

- Chemical Industry Measuring the pressure of aggressive chemicals while preventing corrosion of instruments. - Pharmaceuticals Ensuring accurate pressure measurements in aseptic or sterile environments. - Food and Beverage Monitoring pressures in processes that involve viscous substances, ensuring compliance with hygiene standards. - Oil and Gas Used in upstream and downstream processes for measuring wellhead pressures and processing conditions.

Conclusion

Diaphragm seal pressure gauges, particularly those offered by WIKA, represent an integral part of modern industrial measurement solutions. Their ability to protect against harsh environments, improve accuracy, and extend the lifespan of instrumentation makes them an essential tool for industries worldwide. With innovative designs and custom solutions, WIKA continues to lead the way in providing reliable and accurate pressure measurement technologies, ensuring operational excellence across diverse sectors. Whether it's protecting sensitive equipment from corrosion or improving the accuracy of pressure readings, diaphragm seal pressure gauges are indispensable in maintaining the integrity of industrial processes.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025