Oct . 14, 2024 04:23 Back to list

diaphragm seal differential pressure gauge product

Understanding Diaphragm Seal Differential Pressure Gauges

Diaphragm seal differential pressure gauges are crucial instruments in various industrial applications, designed to measure pressure differences between two points while accommodating the challenges posed by harsh environments. These gauges are particularly useful in processes where the measured media can be corrosive, viscous, or high in temperature, making them indispensable in industries such as oil and gas, chemical processing, and food and beverage.

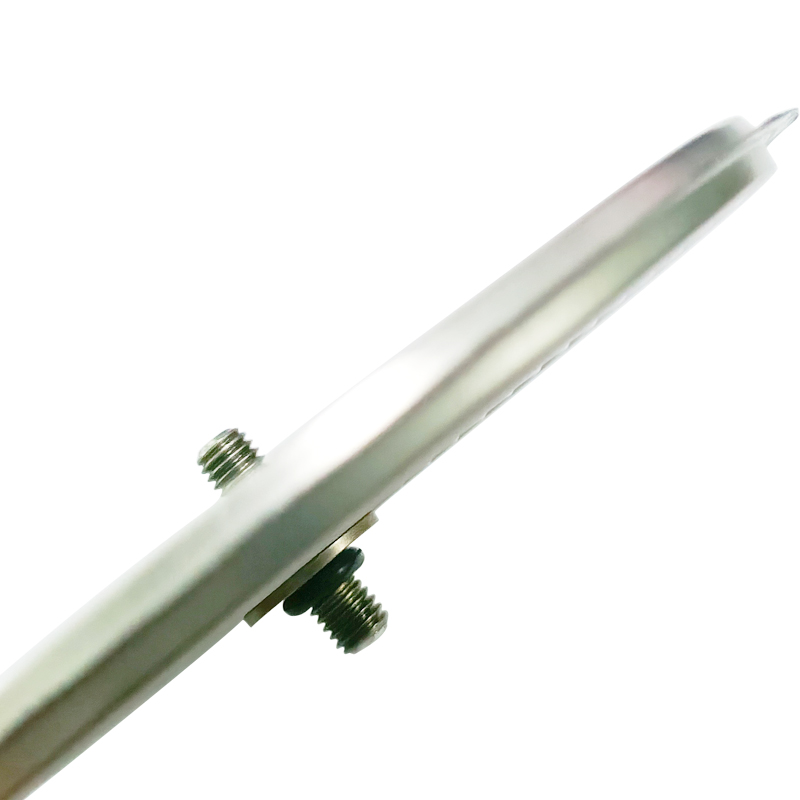

At the heart of a diaphragm seal differential pressure gauge is the diaphragm—a flexible membrane that separates the process fluid from the pressure sensing element. The diaphragm deforms in response to pressure changes, transmitting that deformation to the gauge mechanism. This design not only protects the sensing element from the process media but also enhances the gauge's reliability and accuracy.

One significant advantage of diaphragm seal Gauges is their ability to handle a wide range of pressures and temperatures, which is critical in dynamic industrial environments. The seals can be engineered with various materials, such as stainless steel, Hastelloy, or PTFE, to ensure compatibility with different fluids and to withstand extreme conditions. This versatility makes them suitable for applications ranging from high-pressure hydrocarbon processing to sensitive pharmaceutical manufacturing.

diaphragm seal differential pressure gauge product

Another notable feature of these gauges is their ability to provide a more stable reading in environments where vibrations or pulsations exist. The diaphragm effectively dampens these external influences, resulting in a more accurate differential pressure reading. This quality is essential for maintaining the integrity of processes that depend on precise pressure measurements.

Installation and maintenance are key considerations when working with diaphragm seal differential pressure gauges. Proper installation minimizes the risk of leakage and maximizes the gauge's lifespan. Regular maintenance checks can further enhance performance, ensuring that any potential wear on the diaphragm or seals is addressed promptly.

In summary, diaphragm seal differential pressure gauges are vital tools that offer protection against harsh media while delivering accurate pressure measurements. Their ability to operate effectively under extreme conditions makes them an integral part of modern industrial processes. By selecting the right materials and implementing proper maintenance practices, operators can ensure the longevity and reliability of these essential instruments. Whether used in a chemical plant or a food processing facility, diaphragm seal gauges provide the critical data needed to enhance operational efficiency and safety.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025