Oct . 14, 2024 04:28 Back to list

China's Global Industrial Pressure Gauge Market Trends and Developments Analysis

Understanding China’s Global Industrial Differential Pressure Gauge

In recent years, China has become a significant player in the global industrial market, notably in the field of measuring instruments, including differential pressure gauges. These gauges have a crucial role in various industries, providing essential data necessary for operational efficiency and safety. With China’s advancements in manufacturing technology and a growing emphasis on exports, the country has positioned itself as a pivotal hub for differential pressure gauge production.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument used to measure the difference in pressure between two points in a system. It is commonly employed in various industrial applications, such as monitoring filters, compressors, and fluid flow systems. The readings provided by these gauges are vital for ensuring that systems operate efficiently and safely. If the pressure differential exceeds certain thresholds, it can indicate potential problems, such as blockages or leaks, that need to be addressed promptly.

China's Role in the Market

China holds a significant portion of the global differential pressure gauge market due to its robust manufacturing capabilities and competitive pricing. The country boasts a wide range of manufacturers that specialize in these devices, offering an array of products tailored to different industry needs. As technology evolves, Chinese manufacturers have, in many instances, adapted their production methods to include advanced features and improve overall accuracy and reliability.

Moreover, China's investment in research and development has led to innovative improvements in differential pressure gauge technology. These innovations often involve the integration of digital technology, which allows for real-time monitoring and data analysis, enhancing user experience and operational efficiencies. Consequently, many global industries are increasingly relying on Chinese-made gauges to ensure their systems are functioning optimally.

Quality Standards and Certifications

Despite concerns regarding product quality from some consumers, many Chinese manufacturers of differential pressure gauges comply with strict international quality standards. Certifications such as ISO 9001 and the American National Standards Institute (ANSI) help to establish credibility. These standards ensure that the products not only meet the technical specifications required but also adhere to safety protocols that protect both the equipment and personnel operating in industrial environments.

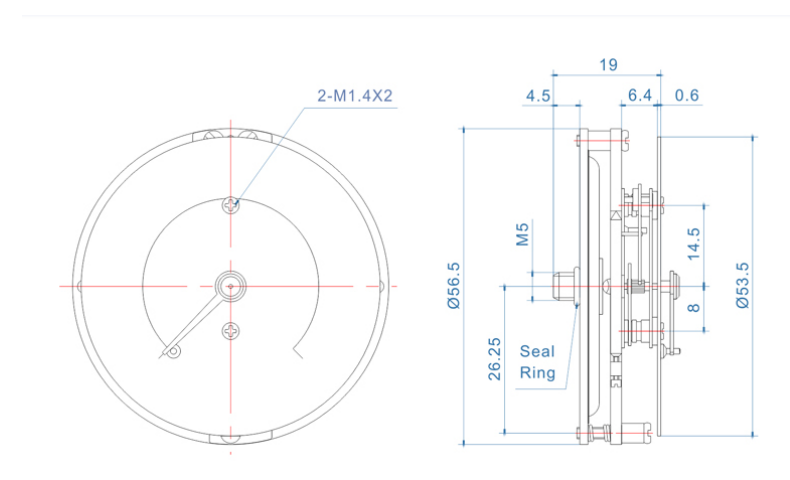

china gobal industrial differential pressure gauge

Economic Implications

The production and export of differential pressure gauges are economically significant for China. The industrial machinery sector is critical to China's overall GDP, and the growing demand for these gauges supports both local economies and employment. As industries worldwide look to optimize their processes and improve efficiencies, the demand for high-quality measuring instruments, including differential pressure gauges, continues to rise.

Furthermore, as countries and companies prioritize sustainability, there is an increasing need for precision measurement tools that can enhance energy efficiency and reduce waste. Chinese differential pressure gauges can play a vital role in these efforts, helping industries track their environmental impact more effectively.

Challenges and Future Perspectives

Despite its many advantages, the Chinese differential pressure gauge market faces challenges. Competition from other countries, particularly those in Europe and North America, is intensifying, as these nations also innovate and offer high-quality products. Additionally, geopolitical tensions can affect global supply chains, potentially disrupting the flow of goods and materials essential for manufacturing.

To maintain its competitive edge, China will need to continue focusing on innovation and quality improvements while fostering relationships with international markets. Investing in smart manufacturing technologies, such as automation and artificial intelligence, could enhance productivity and lower costs, keeping China at the forefront of the differential pressure gauge industry.

Conclusion

In summary, China’s emergence as a global leader in the production of differential pressure gauges highlights its industrial capabilities and commitment to quality. As industries increasingly rely on these critical instruments for operational efficiency, China’s role in the international market will likely grow. By continuing to invest in technology and innovation, Chinese manufacturers can ensure they remain competitive, meeting the evolving needs of the global industrial landscape. As such, the future of differential pressure gauges looks promising, with China poised to be a key player in this essential sector.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025