Nov . 16, 2024 22:41 Back to list

about diaphragm pressure gauge factories

Understanding Diaphragm Pressure Gauges A Comprehensive Overview

Pressure measurement is a critical aspect of various industrial and scientific applications. Among the many types of pressure gauges available, diaphragm pressure gauges stand out due to their unique design and functionality. This article delves into diaphragm pressure gauges, focusing on their construction, working principles, advantages, and applications, while also shedding light on the factories that manufacture them.

What is a Diaphragm Pressure Gauge?

A diaphragm pressure gauge is a device used for measuring the pressure of gases and liquids. Unlike traditional Bourdon tube gauges, diaphragm gauges employ a flexible diaphragm that deforms under pressure. The diaphragm, usually made of materials like stainless steel or brass, is subjected to the pressure from the fluid it is measuring. As the pressure increases, the diaphragm flexes, and this movement is translated into a readable pressure value on the gauge.

Construction and Working Principle

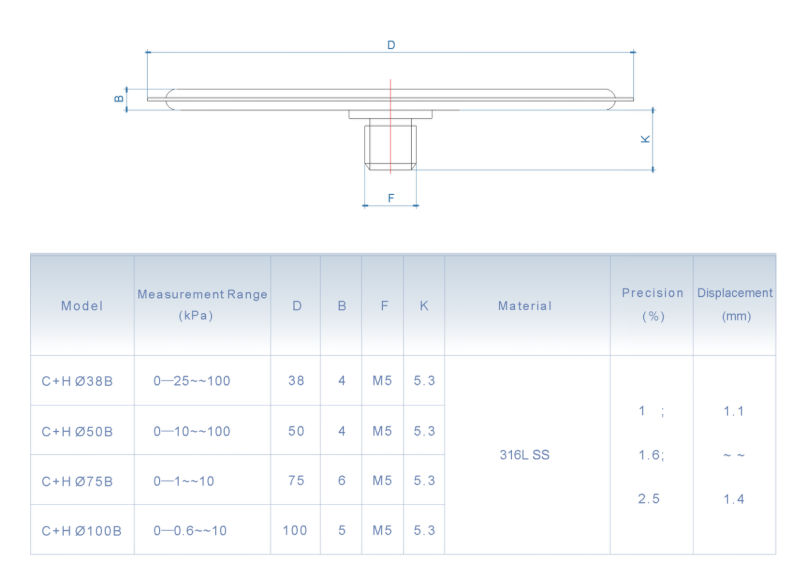

The construction of a diaphragm pressure gauge is relatively straightforward yet ingenious. The gauge consists of a sensing element (the diaphragm), a transmission mechanism (usually a gear arrangement), and a display unit (the dial or digital readout).

When the pressure is applied to one side of the diaphragm, it displaces against the resistance caused by the atmospheric pressure on the other side. This displacement is then converted into a rotary motion through the transmission mechanism, moving the gauge needle to indicate the pressure on the dial. Modern diaphragm gauges can also use electrical transducers for digital readings, facilitating easier integration into automated systems.

Advantages of Diaphragm Pressure Gauges

Diaphragm pressure gauges offer several advantages that make them preferred choices in many applications

2. Suitable for Viscous and Noxious Fluids Diaphragm gauges can measure the pressure of viscous liquids and are often used in applications involving corrosive or toxic substances since they can be designed to include a seal that protects the measuring components.

about diaphragm pressure gauge factories

3. Robustness These gauges are typically designed to withstand harsh environmental conditions, making them robust and reliable.

4. Minimal Maintenance Due to fewer moving parts compared to other gauge types, diaphragm gauges generally require less maintenance over their lifespan.

Applications of Diaphragm Pressure Gauges

Diaphragm pressure gauges are utilized in various industries, including

- Oil and Gas Used for measuring pressure in pipelines and tanks where hazardous substances are handled. - Pharmaceuticals Employed in processes involving sterile environments and easily contaminated substances. - Food and Beverage Ensures that pressure in processing machines and packaging is maintained accurately, ensuring quality control. - Chemical Processing Monitors pressures in reactors, ensuring safe operations in chemical manufacturing.

Manufacturing of Diaphragm Pressure Gauges

The factories that produce diaphragm pressure gauges typically focus on precision engineering and adhere to strict quality standards. The process begins with sourcing high-quality materials to ensure durability and reliability. Advanced machining and fabrication techniques are employed to create the delicate components that make up the gauge, particularly the diaphragm itself.

Quality control procedures are crucial throughout the manufacturing process. Finished products undergo rigorous testing to verify accuracy and performance under various conditions. Many manufacturers also offer customization options, allowing clients to specify materials, size, and pressure ranges based on their specific requirements.

Conclusion

Diaphragm pressure gauges represent a vital tool in many industrial applications, providing accurate and reliable measurements in challenging environments. With their robust design, versatility, and ease of maintenance, these gauges are indispensable in safeguarding processes across multiple sectors. As technology advances, the manufacturing processes for diaphragm pressure gauges continue to evolve, enhancing their performance and expanding their applications in the ever-growing landscape of industry and science. Understanding these devices and their manufacturers is essential for professionals who rely on precision pressure measurement in their operations.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025