Nov . 16, 2024 22:43 Back to list

Miniature Differential Pressure Measurement Gauge for Accurate Readings and Applications

The mini differential pressure gauge is a critical instrument widely used in various industrial and commercial applications to measure pressure differences between two points in a system. This gauge typically comes equipped with advanced features that enhance its functionality and improve the accuracy of measurements, making it indispensable in settings where precise pressure measurements are crucial.

Differential pressure gauges operate on the principle of measuring the difference in pressure between two locations. This is particularly useful in applications such as HVAC systems, where maintaining an optimal pressure differential can lead to improved efficiency and performance. For instance, in air handling units, the mini differential pressure gauge helps monitor the pressure drop across filters, ensuring that they are not clogged and are functioning properly. By providing real-time data, facility managers can proactively conduct maintenance and optimize energy consumption.

The mini differential pressure gauge is a critical instrument widely used in various industrial and commercial applications to measure pressure differences between two points in a system

. This gauge typically comes equipped with advanced features that enhance its functionality and improve the accuracy of measurements, making it indispensable in settings where precise pressure measurements are crucial.Furthermore, mini differential pressure gauges are typically designed with user-friendly interfaces, often incorporating digital displays that provide clear readings. Many models come with features such as adjustable settings, data logging capabilities, and alarm functions that alert users when pressure differentials exceed predetermined thresholds. This level of functionality enables users to analyze trends over time and respond quickly to any irregularities, reinforcing the reliability of the systems being monitored.

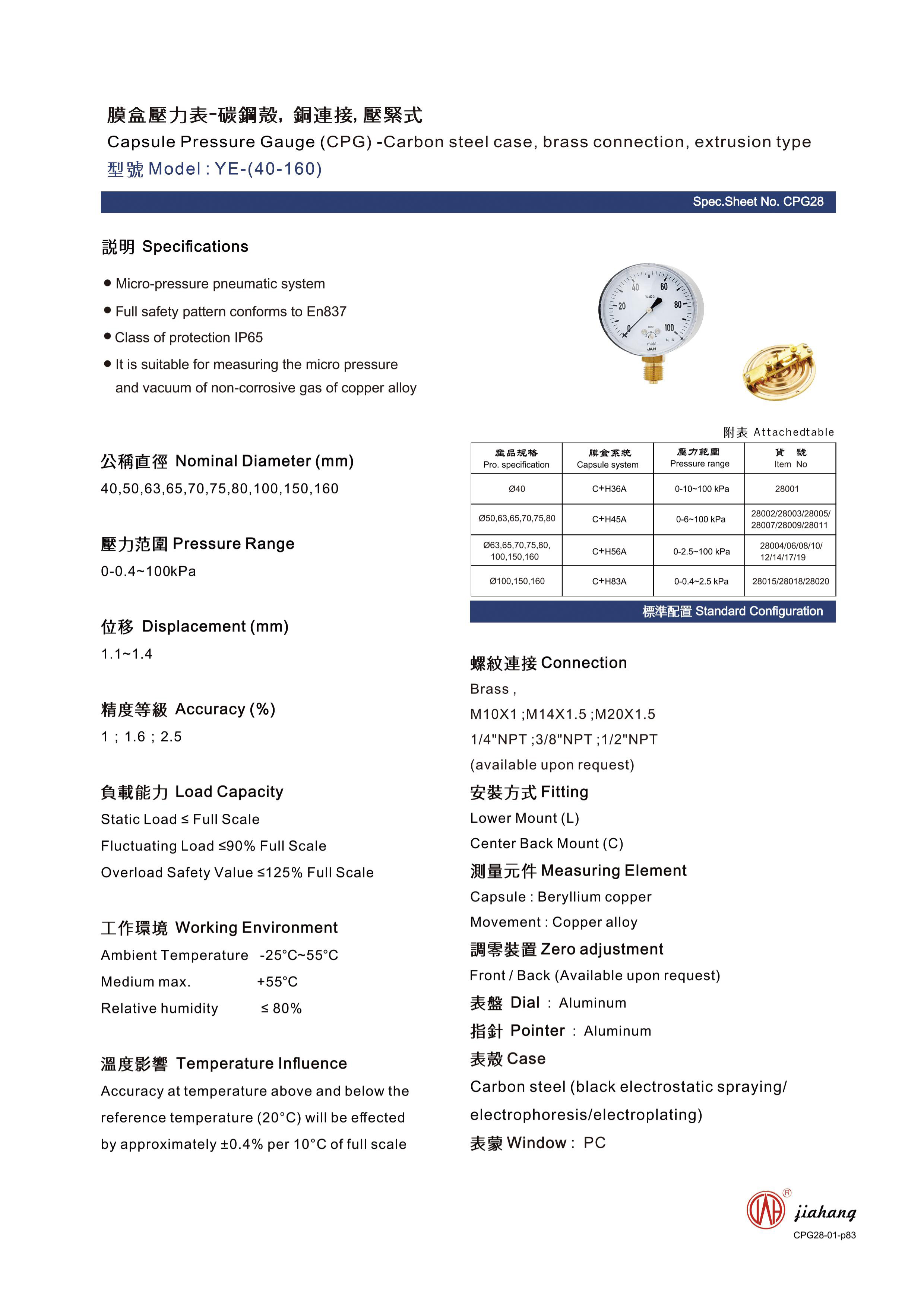

mini differential pressure gauge jah

The selection of materials used in the construction of these gauges is also essential. Many mini differential pressure gauges are manufactured with robust materials resistant to corrosion and other environmental factors, ensuring longevity and consistent performance. Depending on the application, these gauges can be designed to withstand extreme temperatures and conditions, making them versatile enough for various industries, including pharmaceuticals, food processing, and petrochemicals.

As industries increasingly prioritize efficiency and precision, the adoption of mini differential pressure gauges is likely to continue growing. These instruments not only enhance operational efficiency but also contribute to the overall safety of systems by providing essential pressure readings that can prevent equipment failure or hazardous situations. As technology advances, we can expect to see even more sophisticated versions of these gauges, incorporating IoT capabilities for remote monitoring and data analysis.

In conclusion, the mini differential pressure gauge represents a significant advancement in pressure measurement technology. Its compact size, user-friendly design, and robust construction make it a preferred choice across diverse applications. Whether in a commercial HVAC system or a laboratory setting, the importance of accurate differential pressure monitoring cannot be overstated. This instrument plays a vital role in ensuring operational efficiency, safety, and the longevity of the systems it serves, highlighting its value in contemporary industrial practices.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025