Dec . 10, 2024 22:13 Back to list

Manufacturing of Metal Diaphragm Pressure Gauges for Accurate Measurement Solutions

Metal Diaphragm Type Pressure Gauges An Overview

In the realm of industrial pressure measurement, accuracy and reliability are paramount. Among the various types of pressure gauges available, metal diaphragm type pressure gauges have gained significant attention for their robustness and versatility. This article provides an in-depth look at the features, applications, and benefits of metal diaphragm pressure gauges, as well as insights into their manufacturing.

What Are Metal Diaphragm Type Pressure Gauges?

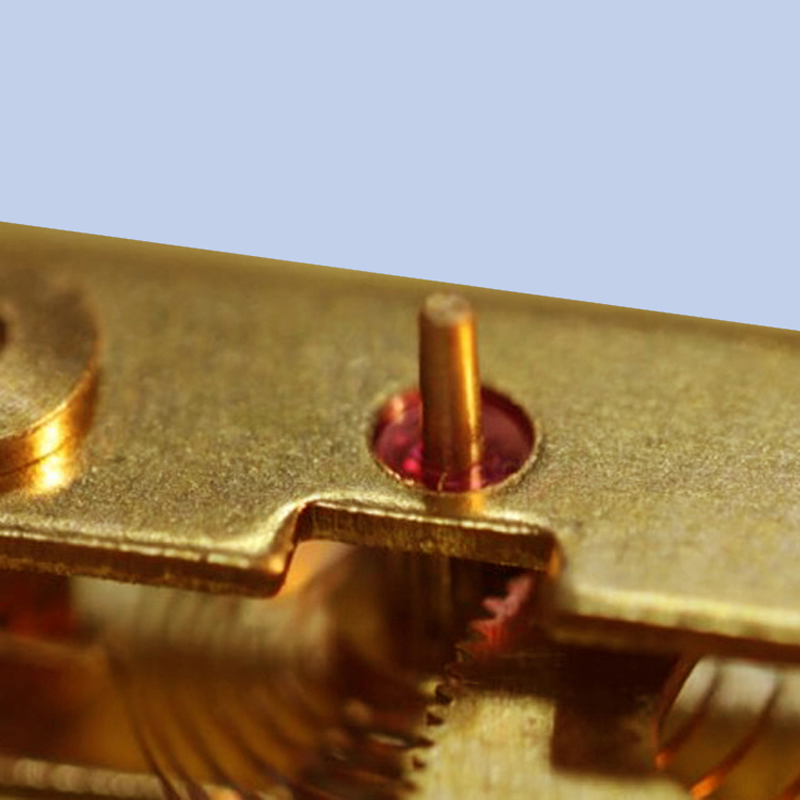

Metal diaphragm type pressure gauges are instruments that utilize a thin, flexible diaphragm made of metal to measure pressure. This diaphragm reacts to the pressure applied, deforming in response to the force exerted on it. The deformation of the diaphragm is transmitted to a pointer or digital readout, which provides a real-time measurement of pressure.

These gauges are designed for high-performance applications, as they can withstand extreme conditions, including high temperature, corrosive environments, and high-pressure situations. The choice of metals for diaphragms, such as stainless steel or Monel, offers excellent resistance to corrosion and fatigue, making them suitable in various industries.

Applications of Metal Diaphragm Pressure Gauges

Metal diaphragm pressure gauges find their application in a wide range of industries. Some of the most common applications include

1. Oil and Gas Industry In this sector, these gauges are used for monitoring the pressure of gases and liquids in pipelines and tanks where reliability is crucial due to potentially hazardous conditions.

2. Chemical Processing The chemical industry often deals with corrosive substances. Metal diaphragm gauges can be used to measure pressure in reactors, filters, and storage units where traditional gauges would fail.

3. Water Treatment Monitoring pressure in water treatment facilities is critical for maintaining system efficiency. Metal diaphragm gauges provide accurate readings in systems handling various water conditions.

metal diaphragm type pressure gauges factory

4. Food and Beverage In the food processing industry, maintaining sanitary conditions is necessary. Metal diaphragm gauges can be designed to meet hygienic standards and used in processes such as pasteurization, filtration, and bottling.

5. Pharmaceuticals The rigorous standards in pharmaceutical manufacturing require reliable pressure measurement devices that do not contaminate the products. Metal diaphragm gauges fit these criteria efficiently.

Benefits of Metal Diaphragm Pressure Gauges

The advantages of metal diaphragm type pressure gauges include

- Durability Due to their construction from robust materials, these gauges perform well under high pressure and temperature, reducing the frequency of replacements and maintenance.

- Wide Range of Compatibility These gauges can handle various media, including corrosive gases and liquids, making them highly adaptable to different applications.

- High Accuracy The precise nature of metal diaphragm measurement allows for accurate monitoring, essential for process control and ensuring safety in industrial applications.

- Low Maintenance With fewer moving parts and a simplified design, metal diaphragm gauges generally require less maintenance compared to traditional mechanical gauges.

Conclusion

In conclusion, metal diaphragm type pressure gauges play a crucial role in the reliable measurement of pressure across various industrial applications. Their durability, accuracy, and adaptability make them a favorite among engineers and technicians alike. As industries continue to evolve, the demand for high-performance and dependable pressure measurement solutions will only increase, positioning metal diaphragm gauges as a key component in modern industrial processes. The advancement of manufacturing techniques promises even greater precision and longevity for these essential instruments, ensuring they remain at the forefront of pressure measurement technology.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025