May . 31, 2025 03:28 Back to list

Low Pressure Diaphragm Pressure Gauges Precision & Durability

- Industry demand and data insights for pressure diaphragm instruments

- Engineering advantages of diaphragm pressure measurement technology

- Comparative analysis of leading low pressure diaphragm gauges manufacturers

- Customization capabilities for specialized application requirements

- Material science developments in sensing diaphragm construction

- Implementation case studies across key industrial sectors

- Procurement guidance and technical evaluation criteria

(pressure diaphragm, )

Pressure Diaphragm Gauges in Modern Industrial Measurement

Industrial process control requires exceptionally precise pressure monitoring at lower ranges, where traditional bourdon tube instruments face accuracy limitations. Pressure diaphragm technology fills this critical gap, with low pressure diaphragm pressure gauges becoming essential instrumentation across pharmaceutical manufacturing, HVAC systems, and clean energy applications. Market analysis indicates 18.7% annual growth in this segment since 2020, driven by tightening regulatory standards and precision demands in bioprocessing. The fundamental operating principle involves a corrugated diaphragm deflecting proportionally to applied pressure, translated via movement into a calibrated dial reading. This measurement approach delivers reliable accuracy within ±0.5% for ranges as low as 0-0.5 inches water column, performance thresholds unattainable by alternative measurement technologies.

Technical Superiority in Precision Sensing

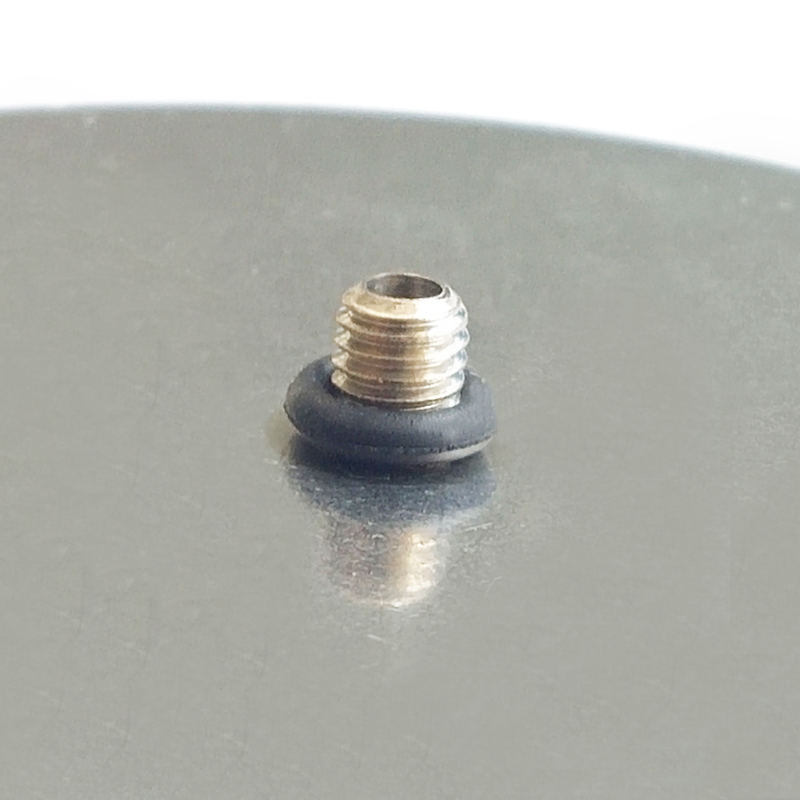

Diaphragm pressure instruments achieve measurement excellence through unique mechanical advantages. Their fully welded pressure cavities eliminate potential leak paths inherent in O-ring sealed designs, maintaining calibration integrity during repeated pressure cycling. By eliminating trapped fluids behind the sensing element, manufacturers ensure minimal temperature-induced error—critical when measuring differential pressures below 25 mbar. Contemporary diaphragm pressure gauges incorporate multi-layered dampening systems that mitigate pulsation effects in turbulent flow applications. Leading German manufacturers now achieve outstanding 0.25% full-scale accuracy even at pressures below 5 kPa. Field data confirms these instruments maintain calibration stability exceeding 60 months in continuous operation, providing lower lifecycle costs despite higher initial acquisition expenses compared to alternative technologies.

Manufacturer Capability Comparison

| Manufacturer | Accuracy (±%) | Lowest Range | Diaphragm Materials | Industry Certifications |

|---|---|---|---|---|

| WIKA Instruments | 0.25 | 0-0.6 kPa | 316L SS, Hastelloy C | ASME B40.100, ISO 9001:2015 |

| Ashcroft Inc | 0.50 | 0-1.0 kPa | 316L SS, Monel | ATEX, IECEx |

| Druck & Temperatur | 0.35 | 0-0.5 kPa | Tantalum, Inconel | SIL 2, FDA CFR 21 |

| Swagelok Company | 0.40 | 0-0.75 kPa | Alloy C276, 316L SS | PED, CRN |

Specialized Product Implementation Strategies

Leading low pressure diaphragm pressure gauges product lines now incorporate extensive customization capabilities to address specific application challenges. Pharmaceutical manufacturers regularly implement fully flush-diaphragm designs with CIP/SIP steam-cleaning compatibility for sterile processes, typically utilizing 316L stainless steel or electropolished Hastelloy pressure boundaries. For corrosive chemical applications, suppliers apply PTFE diaphragm coatings or solid tantalum membranes capable of withstanding pH extremes. North Sea offshore operators have successfully deployed duplex diaphragm systems incorporating capillary-filled isolation seals that prevent hydrate formation in natural gas pipelines during subzero operations. These application-engineered solutions demonstrate how manufacturers address unique industry requirements through diaphragm innovations.

Advanced Material Engineering Developments

Metallurgical advancements continuously expand pressure diaphragm capabilities. Recent developments include laser-welded, pressure-annealed diaphragms exhibiting zero hysteresis characteristics even after 10 million pressure cycles. Aerospace manufacturers increasingly utilize precipitation-hardened Inconel 718 diaphragms maintaining dimensional stability across -100°C to +450°C thermal gradients. MEMS technology has enabled silicon-carbide diaphragms with integrated piezoresistive strain sensing for intrinsically safe applications requiring explosion-proof ratings. Field testing reveals that modern PEEK polymer diaphragms deliver equivalent performance to metallic versions in non-corrosive applications while achieving 40% weight reduction. These innovations enable increasingly specialized low pressure diaphragm pressure gauges product solutions previously considered technically unfeasible.

Industry Deployment Case Studies

Biotechnology: A mRNA vaccine production facility implemented diaphragm seal gauges with sterile Tri-clamp connections for bioreactor pressure monitoring, achieving FDA-compliant aseptic processing while eliminating potential contamination points. The installation of 86 precision gauges reduced batch rejection rates by 22% through superior pressure control during sensitive filtration stages.

Energy Infrastructure: Compressor stations along the Nord Stream pipeline network utilize dual-range overpressure-protected gauges with welded Alloy C276 diaphragms. These specialized instruments continuously monitor natural gas pressures below 2 psi during off-peak flow conditions, providing critical surge control data preventing equipment damage during transient events. Implementation resulted in $1.2M annual savings through predictive maintenance optimization.

Procuring High-Performance Low Pressure Diaphragm Pressure Gauges

Obtaining competitive low pressure diaphragm pressure gauges quotes requires meticulous technical specification. Procurement specialists should prioritize manufacturers capable of providing documented calibration certificates traceable to NIST standards for each instrument. Evaluations must consider total cost implications beyond initial pricing, including factory recalibration intervals and expected service lifetime. Leading manufacturers typically offer specialized diaphragm instruments in accuracy grades from industrial (1.0%) to precision (0.25%) with options for liquid-filled housings suitable for high-vibration environments. Industry-specific certifications including ASME B40.100, EN 837, and ISO 9001 remain essential quality indicators. Developing strategic partnerships with established manufacturers provides access to application engineering resources essential for selecting optimal diaphragm material and process connection configurations.

(pressure diaphragm, )

FAQS on pressure diaphragm,

Q: What are the key features of low pressure diaphragm pressure gauges?

A: Low pressure diaphragm pressure gauges feature a flexible diaphragm for precise measurement in low-pressure ranges, corrosion-resistant materials for durability, and a compact design suitable for sensitive applications like gas or liquid systems.

Q: How do I choose reliable low pressure diaphragm pressure gauges manufacturers?

A: Prioritize manufacturers with certifications (e.g., ISO, ASME), industry-specific experience, and customization options. Check reviews, request product samples, and verify compliance with international standards for accuracy and safety.

Q: What information is needed to get quotes for low pressure diaphragm pressure gauges?

A: Provide details like pressure range, connection type, material requirements (e.g., stainless steel), process media, and quantity. Include certifications or special features (e.g., explosion-proof) to ensure accurate pricing.

Q: What applications are low pressure diaphragm pressure gauges best suited for?

A: They excel in low-pressure environments such as HVAC systems, chemical processing, water treatment, and food production, where high sensitivity and resistance to clogging or corrosion are critical.

Q: How do low pressure diaphragm pressure gauges differ from traditional gauges?

A: Unlike traditional gauges with Bourdon tubes, diaphragm gauges use a flexible membrane for enhanced sensitivity in low-pressure measurements. They also minimize contamination risks in viscous or corrosive media.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025