Nov . 09, 2024 09:50 Back to list

Understanding the Functionality of Diaphragm Pressure Gauges in Measurement Applications

Understanding ODM Diaphragm Pressure Gauges

In various industrial applications, accurate pressure measurement is vital for ensuring the safety, efficiency, and reliability of operations. Among the many types of pressure gauges available, the ODM diaphragm pressure gauge stands out due to its unique design and performance characteristics. This article explores the functionality, design, and applications of ODM diaphragm pressure gauges, providing insights into their importance in modern industry.

What is a Diaphragm Pressure Gauge?

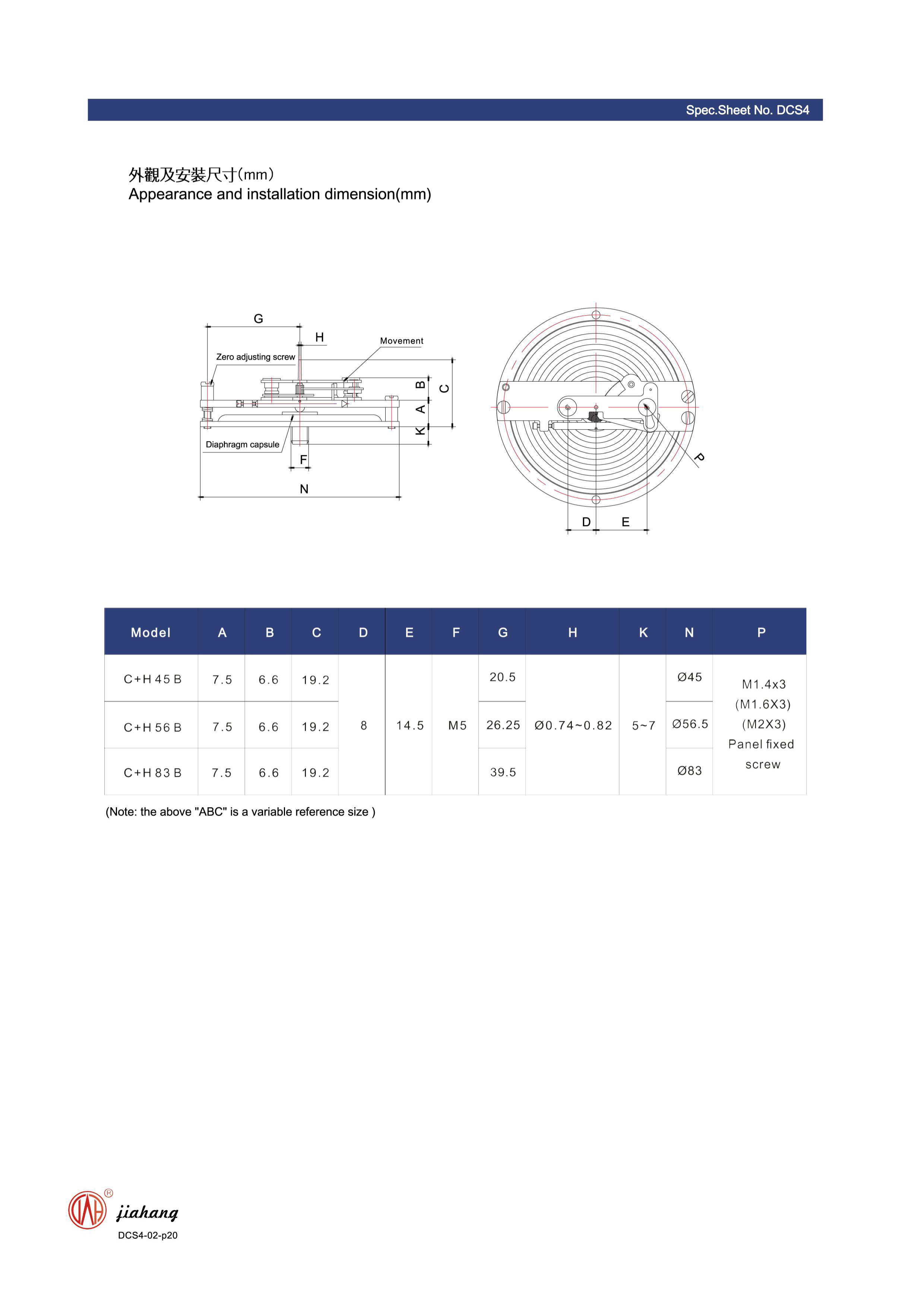

A diaphragm pressure gauge is a type of pressure measurement device that employs a flexible diaphragm to sense pressure changes. When pressure is applied to one side of the diaphragm, it deforms, and this deflection is transmitted to a mechanical or electronic system that translates this movement into a readable pressure value. ODM, which stands for Original Design Manufacturer, signifies that these gauges are designed and manufactured by a specific company known for its innovative and reliable products.

Design Features

One of the key features of ODM diaphragm pressure gauges is their robust construction, allowing them to operate effectively in various harsh environments. These gauges often utilize high-quality materials such as stainless steel or special alloys, making them resistant to corrosion and capable of handling high-pressure applications.

The diaphragm itself is typically designed to be sensitive yet durable, providing precise measurements while maintaining integrity over extended periods of use. Additionally, ODM gauges often include features such as temperature compensation and overpressure protection, which enhance their performance in fluctuating conditions.

odm the diaphragm pressure gauge

Working Principle

The working principle of the ODM diaphragm pressure gauge is relatively straightforward. As pressure is applied, the diaphragm bends proportionally to the pressure exerted. This bending action is directly linked to a mechanical pointer that moves across a calibrated dial, displaying the pressure reading. For electronic versions, the diaphragm movement can be converted into an electrical signal, further enhancing accuracy and allowing for digital readouts.

Applications

ODM diaphragm pressure gauges are utilized across a wide range of industries, including oil and gas, pharmaceuticals, food and beverage, and water treatment. Their versatility makes them suitable for applications involving gases, liquids, and even viscous materials, ensuring that businesses can rely on them for accurate pressure monitoring.

In the oil and gas sector, for example, these gauges help monitor pipeline pressure, ensuring operations remain within safe limits. In the pharmaceutical industry, where precision is paramount, diaphragm gauges ensure that equipment operates effectively during manufacturing processes, maintaining the quality of the products.

Conclusion

In conclusion, ODM diaphragm pressure gauges play a critical role in numerous industrial applications by providing reliable and accurate pressure measurements. Their durable design, precision engineering, and adaptability make them an invaluable tool for any operation requiring pressure monitoring. As industries continue to evolve, the importance of these gauges in maintaining operational safety and efficiency will undoubtedly increase, solidifying their status as a cornerstone of modern industrial measurement technology. Investing in high-quality ODM diaphragm pressure gauges not only ensures accuracy in measurements but also contributes to the overall success and safety of operations across various sectors.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025