Nov . 27, 2024 15:14 Back to list

OEM Sealed Diaphragm Pressure Gauge for Accurate Measurements in Various Applications

Understanding OEM Sealed Diaphragm Pressure Gauges

When it comes to measuring pressure in various applications, the importance of choosing the right equipment cannot be overstated. Among the many devices available, the OEM (Original Equipment Manufacturer) sealed diaphragm pressure gauge stands out for its precision, reliability, and durability. These gauges are widely used in numerous industries, including automotive, chemical, pharmaceutical, and HVAC, due to their versatility and robust design.

What is a Sealed Diaphragm Pressure Gauge?

A sealed diaphragm pressure gauge is a type of pressure measuring device that utilizes a flexible diaphragm to detect changes in pressure. This diaphragm separates the measuring fluid from the environment, ensuring that the gauge is unaffected by outside variables such as dust, moisture, or corrosive materials. In an OEM context, these gauges are specifically designed and manufactured to meet the unique requirements of particular equipment or applications, ensuring optimum performance.

How Does it Work?

The working principle of a sealed diaphragm pressure gauge is fairly straightforward. When pressure is applied to the gauge, it exerts force on the diaphragm. This diaphragm then flexes in response to the pressure change. The movement of the diaphragm is mechanically translated into a reading on the gauge face, usually in psi (pounds per square inch) or bar. The accuracy and reliability of the measurements provided by these gauges are critical, particularly in sensitive applications like pharmaceuticals, where precise pressure control is essential for product integrity.

Key Features

1. Sealing Mechanism The sealed nature of the diaphragm protects the internal components from contamination and environmental factors, making it ideal for harsh operating conditions.

2. Durability These gauges are designed to withstand extreme pressures and temperatures, ensuring longevity even in demanding applications.

3. Customization As OEM products, these pressure gauges can be tailored to specific needs, including materials, size, and pressure ranges, making them adaptable to a broad spectrum of industrial applications.

4. Accuracy High-quality OEM sealed diaphragm pressure gauges provide precise readings, reducing the risk of errors that could lead to operational inefficiencies or safety hazards.

Applications of OEM Sealed Diaphragm Pressure Gauges

Given their robust construction and reliability, OEM sealed diaphragm pressure gauges are employed in numerous sectors

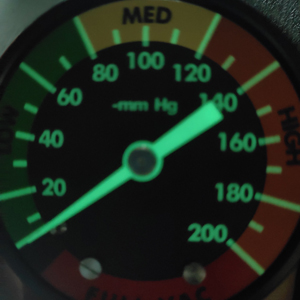

oem sealed diaphragm pressure gauge

- Chemical Industry For monitoring and controlling the pressure of various chemical processes, where precision is crucial for safety and product quality

.- Pharmaceuticals In drug manufacturing, where maintaining precise pressure levels is essential for product consistency and compliance with regulatory standards.

- Food Processing To ensure that processes meet safety standards and maintain the quality of products.

- HVAC Systems To measure the pressure in heating, ventilation, and air conditioning systems, ensuring optimal performance and energy efficiency.

- Oil and Gas In drilling operations, where accurate pressure measurements can prevent blowouts and enhance safety.

Advantages of Using OEM Sealed Diaphragm Pressure Gauges

1. Improved Safety By providing accurate pressure readings, these gauges help mitigate risks associated with overpressure situations that could lead to equipment failure or accidents.

2. Enhanced Process Control Reliable pressure measurement allows for better regulation of processes, improving overall efficiency and product quality.

3. Cost-Effectiveness Though the initial investment may be higher, the long lifespan and reduced maintenance requirements of these gauges often make them a more economical choice in the long run.

4. Easy Integration The customization capabilities of OEM products mean that they can be easily integrated into existing systems without the need for significant modifications.

Conclusion

In conclusion, OEM sealed diaphragm pressure gauges are critical tools for accurately measuring pressure across various industries. Their design, which allows for customizable features and superior protection against environmental factors, makes them essential for applications where accuracy and reliability are paramount. As industries continue to evolve and demand more from their equipment, the importance of high-quality pressure measurement instruments like the OEM sealed diaphragm pressure gauge will only continue to grow. Investing in these instruments ensures optimal performance, safety, and compliance with industry standards, making them indispensable in modern industrial applications.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025