11 月 . 11, 2024 11:56 Back to list

high precision pressure gauge jah

High Precision Pressure Gauges The Unsung Heroes of Industrial Measurement

In the ever-evolving landscape of industrial manufacturing and process control, precision often serves as the cornerstone of operational efficiency and product quality. Among the myriad of instruments employed to ensure adherence to this precision is the high precision pressure gauge. These gauges play a critical role in various sectors, including petrochemical, pharmaceutical, aerospace, and food and beverage industries, where precision is not just a requirement but a necessity.

High Precision Pressure Gauges The Unsung Heroes of Industrial Measurement

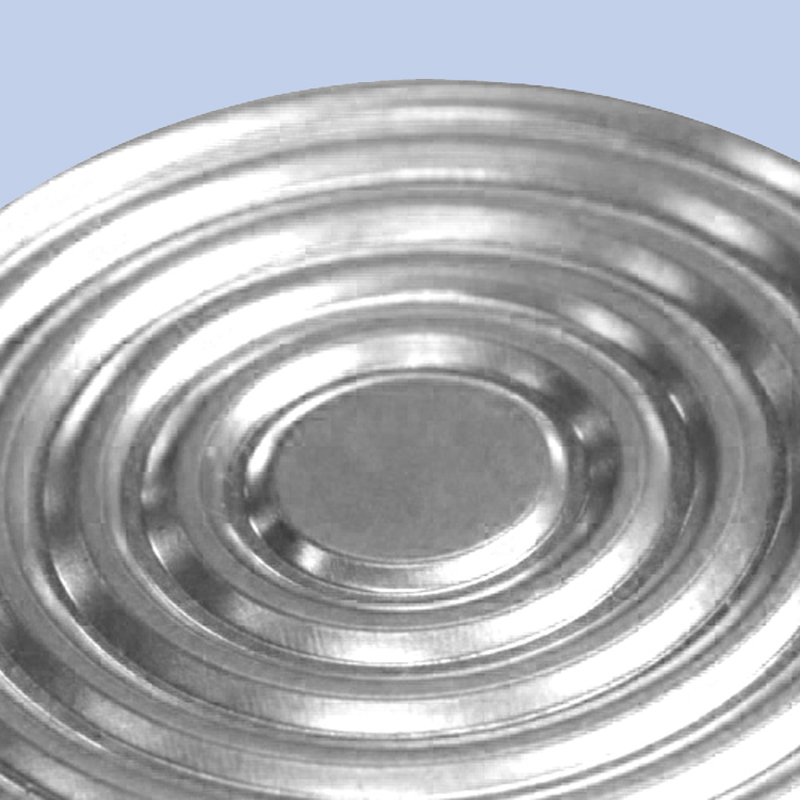

One of the key features of high precision pressure gauges is their robust construction, which often includes stainless steel casings, advanced sensing technologies, and protective features against temperature fluctuations and vibrations. These gauges are typically used with various calibration standards to ensure that their measurements are consistent and reliable over time. The importance of calibration cannot be overstated; ensuring that each gauge is properly calibrated is essential for maintaining process integrity and avoiding costly production downtimes.

high precision pressure gauge jah

In sectors such as the chemical industry, where precise pressure measurement is crucial for reactor safety and efficiency, high precision pressure gauges can help prevent catastrophic failures that could arise from pressure fluctuations. For instance, maintaining optimum pressure levels during chemical reactions can significantly affect yield and product quality. The same can be said about the pharmaceutical industry, where regulatory compliance often mandates strict monitoring of pressure conditions to ensure that the production meets safety and quality standards.

Technological advancements have also greatly enhanced the capabilities of high precision pressure gauges. With the integration of digital displays and IoT capabilities, modern gauges can now transmit data to centralized control systems, allowing for real-time monitoring and analysis. This connectivity not only improves the responsiveness of operations but also aids in preventive maintenance by providing insights into gauge performance over time. As industries pivot toward automation and smart manufacturing, high precision pressure gauges have become integral to achieving these innovations.

Moreover, the application of high precision pressure gauges is not limited to industrial uses. They are also vital in research and development settings, where experimentation often requires precise measurement to yield valid results. In laboratories, these gauges ensure that tests are conducted under controlled pressure conditions, allowing scientists to predict outcomes with greater accuracy.

In conclusion, while high precision pressure gauges may not be the most glamorous tools in the industrial toolbox, their importance cannot be understated. These instruments ensure the safety, efficiency, and quality of processes across various sectors, significantly contributing to the overall success of operations. With continuous advancements in technology and a growing focus on precision across industries, the demand for high precision pressure gauges is expected to rise. As industries strive to meet increasingly stringent standards and customer expectations, these gauges will undoubtedly remain an essential component of process management, driving innovation and efficiency forward. In an age where precision is paramount, investing in high quality pressure measurement instruments is not just prudent; it is essential for success in an increasingly competitive landscape.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025