12 月 . 27, 2024 05:21 Back to list

china piston differential pressure gauge

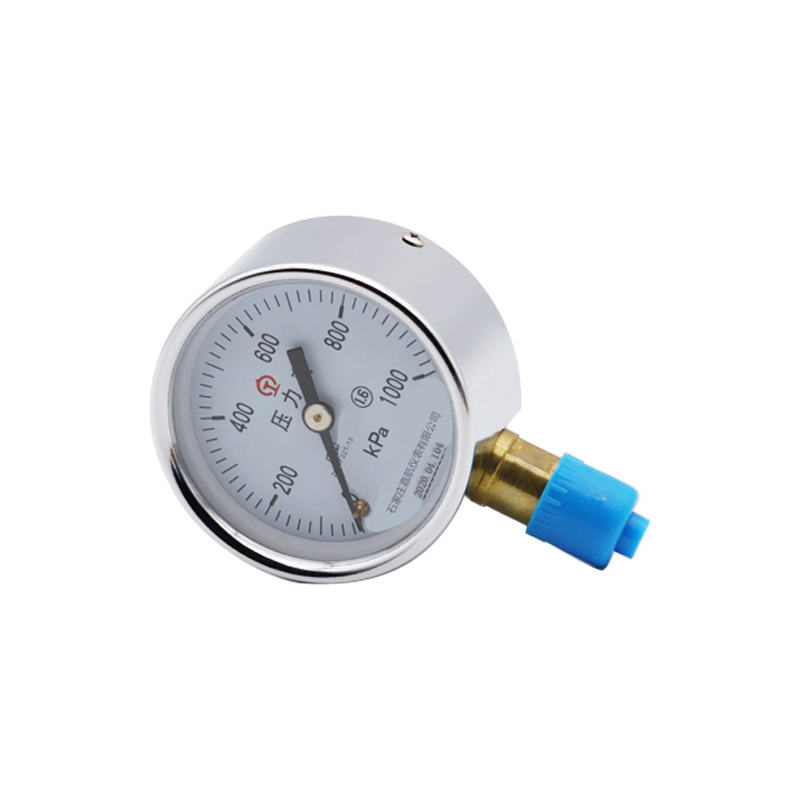

Understanding the China Piston Differential Pressure Gauge

In various industrial applications, measuring pressure accurately is crucial for maintaining operational efficiency and safety. One of the essential tools for this purpose is the piston differential pressure gauge. This device is widely utilized in China and other countries to monitor pressure differences in liquid and gas systems. Its functionality, design, and applications are vital to comprehend for anyone involved in engineering, manufacturing, or quality control processes.

What is a Piston Differential Pressure Gauge?

A piston differential pressure gauge is a device that measures the difference in pressure between two points in a system. At the core of this gauge is a piston that moves in response to pressure variations. The piston is typically housed in a cylinder, allowing it to slide freely. When pressure is applied to one side of the piston, it moves to a position that correlates with the strength of the pressure differential. The resulting movement is translated into a readable measurement, often in units like PSI (pounds per square inch) or bar.

Key Components and Mechanism

The primary components of a piston differential pressure gauge include the piston, cylinder, springs, and a dial or digital readout for displaying measurements. When pressure is applied, the piston is displaced, causing a corresponding change in the position of a dial indicator or digital sensor. The gauge can have one or two pressure inlet ports, depending on whether it monitors two different points in the same system or compares two distinct systems.

The mechanism is relatively straightforward as the pressure differential increases, the piston moves further within the cylinder, which translates into a higher reading on the gauge. This design allows for high accuracy and reliability, making it vital for numerous applications, particularly in industrial settings where pressure regulation is pivotal.

Applications in Industry

china piston differential pressure gauge

In China, the piston differential pressure gauge finds application across various industries, including oil and gas, chemical manufacturing, water treatment, and HVAC systems. Engineers rely on this gauge to ensure that the system operates within safe limits, preventing overpressure situations that could lead to equipment failure or safety hazards.

For instance, in oil refineries, monitoring pressure differentials can help identify blockages in pipelines or leaks in tank systems. Similarly, in water treatment facilities, these gauges are used to oversee filtration systems, ensuring that pressure differences remain within acceptable ranges for optimal functioning.

Advantages of Using Piston Differential Pressure Gauges

One of the significant advantages of piston differential pressure gauges is their robustness. Unlike other types of pressure gauges, they are less susceptible to vibrations and temperature fluctuations, which can lead to inaccurate readings. Additionally, these gauges can handle a variety of fluid types, including those that are viscous or corrosive, making them versatile for many applications.

Another advantage is their simplicity of design, which leads to ease of maintenance. Regular calibration is needed to ensure accuracy, but the straightforward mechanism allows for quick servicing when necessary.

Conclusion

The China piston differential pressure gauge is an invaluable tool in modern industry, providing critical pressure measurements to ensure the smooth operation of various systems. Its design offers reliability and durability, while its widespread application demonstrates its importance in maintaining safety and efficiency in numerous industrial processes. As technology continues to advance, we can expect enhancements in the accuracy and capabilities of these gauges, making them even more indispensable in ensuring operational excellence across sectors. For engineers, operators, and maintenance personnel, familiarity with the function and application of piston differential pressure gauges is essential to safeguard systems and enhance overall productivity.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025