Nov . 20, 2024 10:47 Back to list

diaphragm type differential pressure gauge product

Understanding Diaphragm Type Differential Pressure Gauges

Differential pressure gauges are essential instruments widely used in various industries to measure the difference in pressure between two points. Among the most effective types of these devices is the diaphragm type differential pressure gauge. This technology harnesses the principle of a flexible diaphragm, which deflects in response to pressure changes, thus providing accurate readings.

How Diaphragm Differential Pressure Gauges Work

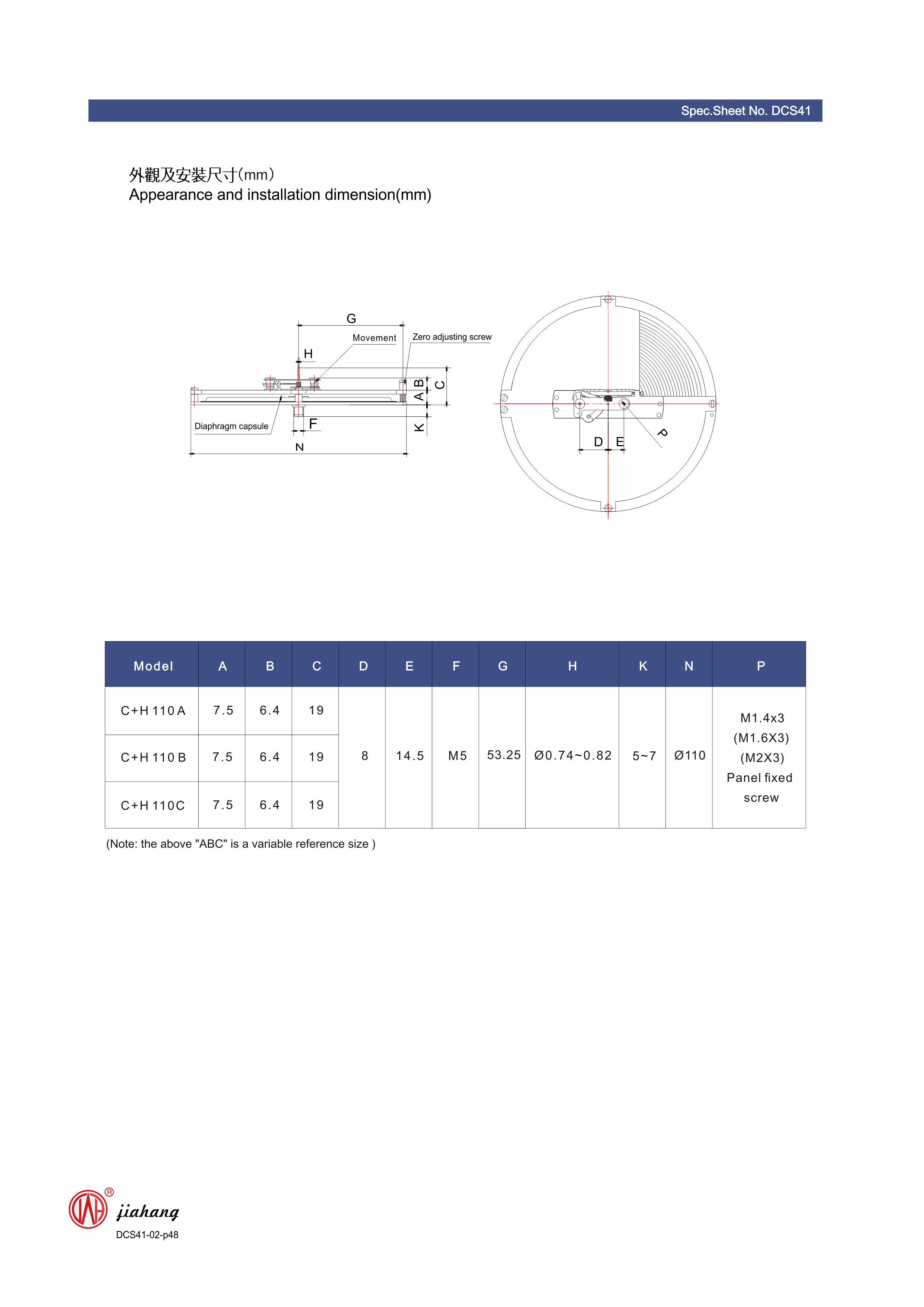

The core component of a diaphragm type gauge is the diaphragm, a thin, elastic membrane that separates two pressure chambers. When pressure is applied to one side of the diaphragm while the other side is exposed to a different pressure, the diaphragm flexes or deflects. This deflection is directly related to the pressure difference between the two spaces. The movement of the diaphragm is then translated into a measurable output, typically via a mechanical or electronic transducer that drives a needle on a dial or provides a digital reading.

Applications of Diaphragm Type Differential Pressure Gauges

These gauges are remarkably versatile and are utilized across numerous applications. In the oil and gas industry, diaphragm gauges play a critical role in monitoring pressure in pipelines and storage tanks, ensuring safe and efficient operations. In HVAC systems, they are essential for measuring the pressure drop across filters and coils, leading to better operational efficiency and maintenance practices.

diaphragm type differential pressure gauge product

Another prevalent application is in the pharmaceutical and food processing industries, where maintaining specific pressure differentials is vital for contamination control and product integrity. Here, the diaphragm's ability to provide accurate pressure readings helps maintain sterile conditions.

Advantages of Diaphragm Type Differential Pressure Gauges

One of the key benefits of diaphragm type gauges is their robustness. They are well-suited for use in harsh environments, including those with high levels of vibration or temperature fluctuations. The simplicity of their design also contributes to their reliability, leading to minimal maintenance needs and an extended service life. Furthermore, these gauges can be customized to meet specific industry requirements, such as varying pressure ranges and materials that can withstand corrosive substances.

Another significant advantage is the ability to provide highly accurate measurements. The sensitivity of the diaphragm allows for the detection of small pressure changes, which can be critical in applications where precision is paramount. This sensitivity is often enhanced by the use of advanced materials and design techniques, enabling measurements to be taken in a wide range of operating conditions.

Conclusion

Diaphragm type differential pressure gauges are an indispensable tool in various industrial applications. Their design leverages the principles of mechanics to deliver accurate, reliable measurements of pressure differences. With their robustness, versatility, and high sensitivity, these gauges are ideal for ensuring safe and efficient operations in some of the most demanding environments. As technology advances, we can expect further enhancements in these gauges, leading to even greater accuracy and reliability in the measurement of differential pressures across industries. Understanding their functionality and applications is crucial for professionals involved in systems reliant on precise pressure measurements.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025