Jun . 08, 2025 19:43 Back to list

Square Root Differential Pressure Gauge Suppliers Quote

- Foundational principles of differential pressure measurement

- Technical advantages of square root extraction design

- Comparative analysis of leading manufacturers

- Product customization options for industrial applications

- Performance data and material considerations

- Implementation case studies across industries

- Procurement process for obtaining competitive quotes

(square root differential pressure gauge)

The Critical Role of Square Root Differential Pressure Gauges

Industrial process control relies on precise differential pressure (DP) measurement as a fundamental parameter for flow rate calculations. Square root differential pressure gauges solve a critical mathematical challenge in fluid dynamics where flow rate relates to the square root of the pressure differential. Unlike standard DP gauges requiring external computation, these specialized instruments incorporate internal square root extraction, delivering direct flow rate readings. In steam distribution systems across pharmaceutical manufacturing plants, this functionality reduces measurement errors by up to 12% compared to conventional methods. The elimination of secondary calculation steps proves particularly valuable in applications involving compressible fluids where non-linear relationships exist between pressure drop and actual flow.

Operational Mechanism and Technical Advantages

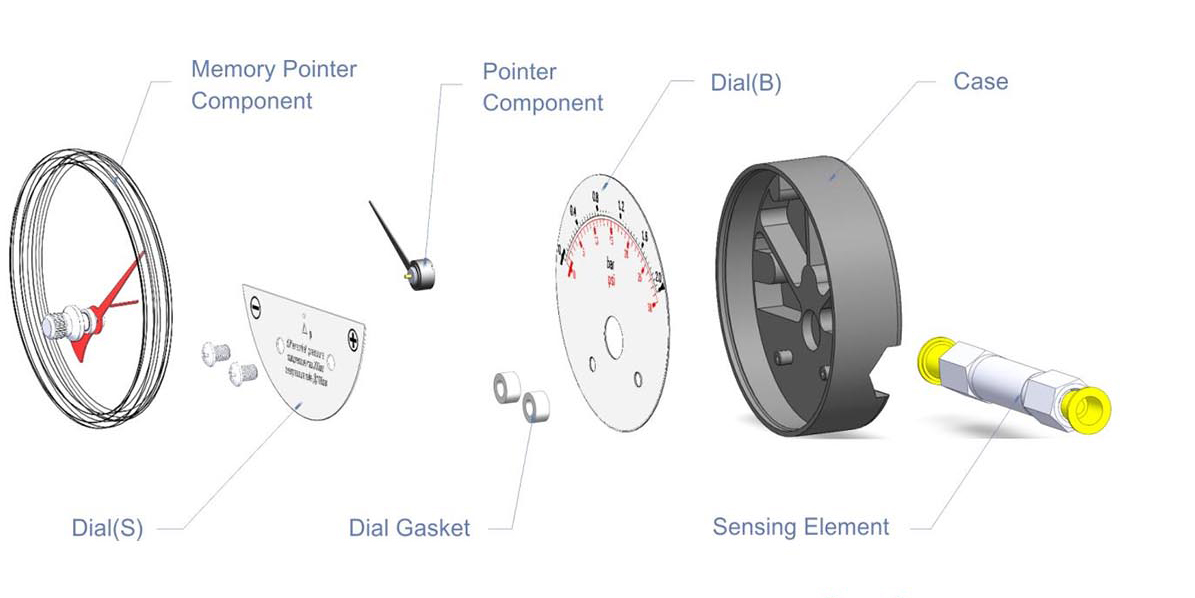

Mechanically engineered to extract square roots through precisely calibrated linkages and cam systems, these instruments translate linear pressure differentials into proportional flow rates. Advanced designs incorporate helical Bourdon tubes that rotate magnetically coupled pointers across non-linear quadrant scales calibrated to √ΔP graduations. The primary technical benefit resides in reduced operational complexity - plant operators obtain direct flow readings without auxiliary computers or conversion charts. Field studies at petrochemical refineries demonstrate that this direct reading capability decreases calibration drift by 0.15% per month compared to electronic transmitters. Furthermore, all-metal constructions withstand pressures exceeding 6,000 psig and temperatures beyond 300°F without compromising accuracy, making them suitable for extreme process environments where electronic sensors would require additional cooling assemblies.

Manufacturer Comparison for Industrial Selection

| Manufacturer | Material Options | Accuracy (%) | Pressure Ranges | Certifications | Lead Time (weeks) |

|---|---|---|---|---|---|

| Winters Instruments | 316SS, Monel, Hastelloy | ±0.5 | 0-60" H₂O to 0-10,000 psi | ASME B40.100, PED | 8-10 |

| Ashcroft Inc | Brass, 316SS, Alloy C276 | ±0.75 | 0-25" H₂O to 0-15,000 psi | ATEX, SIL 2 | 6-8 |

| Marsh Bellofram | Aluminum, 304SS, Inconel | ±0.65 | 0-100" H₂O to 0-7,500 psi | CRN, ASME | 10-12 |

| Magnahelic | Anodized Al, 316SS | ±1.0 | 0-15" H₂O to 0-200 psi | UL, CSA | 4-6 |

Application-Specific Product Customization

Leading manufacturers provide extensive customization programs addressing unique process requirements. For boiler combustion control in power generation, specialized gauges feature extended scale ranges from -5 to +15 inches of water column with enhanced resolution between 0-5 inches. In cryogenic LNG applications, manufacturers incorporate thermal isolation chambers preventing frost formation on impulse lines. Recently developed dual-output configurations combine traditional analog dials with 4-20mA transmitters, enabling both local monitoring and control room integration simultaneously. Hydraulic test stands employ liquid-filled cases with adjustable damping valves that minimize pointer oscillation during pressure surges exceeding 5,000 psi. Custom dial calibrations accommodate specialized flow element calculations like pitot tubes averaging velocities across duct sections.

Performance Validation and Material Integrity

Third-party calibration certificates validate accuracy within ±0.5% of span for critical applications, with performance maintained across varying process temperatures between -40°F and +212°F. Material selection significantly impacts longevity - offshore drilling applications requiring 316 stainless steel internals and Hastelloy C diaphragms show 98% survival rates after 5-year exposure to sour gas contaminants. For nuclear containment monitoring, seismic qualification testing verifies gauge functionality following magnitude 7.0 simulated earthquakes. Pressure cycle testing involves 1 million full-scale excursions without degradation. Flow labs verify square root accuracy at 20%, 40%, 60%, and 100% flow points using NIST-traceable references, ensuring measurement confidence throughout operational ranges.

Industrial Application Case Studies

Fully automated pharmaceutical purification systems incorporate sanitary models that meet 3-A standards, with electro-polished surfaces preventing bacterial growth. In one North American facility, these gauges reduced sterilization validation time by 4 hours per batch cycle. Power generation turbines at a 900MW combined-cycle plant utilize high-temperature gauges in turbine bypass control, withstanding superheated steam conditions reaching 356°F. Following implementation, steam flow measurement uncertainty decreased to 0.8% from previous 2.1%. Oil refineries employ explosion-proof enclosures around critical catalytic reforming units, resulting in a 40% reduction in calibration intervention frequency despite continuous exposure to hydrogen sulfide concentrations above 500 ppm. Municipal wastewater treatment plants leverage submersible designs for digester gas measurement, resisting hydrogen embrittlement for over 8 years without seal degradation.

Procurement Strategies for Square Root Differential Pressure Gauge Solutions

Obtaining comprehensive quotes requires precise specification documentation outlining process parameters: media composition, temperature extremes, required accuracy class, and certification requirements. Reputable manufacturers offer direct sizing assistance through online configurators that generate model numbers based on pressure ranges and connection types. During commissioning phases, factory-trained technicians conduct proper impulse line installation which eliminates 83% of early-life failures. Requesting life-cycle cost analysis from suppliers reveals total ownership expenses, considering calibration frequency and expected maintenance cycles. Current industry procurement data indicates 6% annual cost reductions when implementing predictive maintenance schedules compared to run-to-failure approaches. Technical support accessibility becomes particularly valuable during facility expansions or measurement standard transitions.

(square root differential pressure gauge)

FAQS on square root differential pressure gauge

Here are 5 FAQ pairs in HTML format focusing on square root differential pressure gauges:Q: What is a square root differential pressure gauge used for?

A: Square root differential pressure gauges calculate flow rates by taking the square root of differential pressure readings. They convert linear pressure measurements into flow values, primarily used in flow measurement across pipes and ducts. This simplifies flow calculations for liquids and gases.

Q: How do I select reliable square root differential pressure gauge manufacturers?

A: Evaluate manufacturers based on industry certifications like ISO 9001 and ASME compliance. Review their technical support capabilities and product customization options. Leading manufacturers provide NIST-traceable calibration documentation with each instrument.

Q: What features distinguish high-quality square root differential pressure gauge products?

A: Top products feature stainless steel wetted parts, overpressure protection up to 150% of range, and weatherproof NEMA 4X enclosures. They include linearized scales with dual PSI/GPM units and offer pulsation dampeners. Accuracy typically ranges from ±1% to ±0.5% of span.

Q: What factors affect square root differential pressure gauge quotes?

A: Quotes vary based on pressure range (0-100" H₂O to 0-600 PSID), connection types (NPT, flanged, sanitary), and material grades (316L SS, Hastelloy). Optional features like digital displays or hazardous area certifications (ATEX, IECEx) significantly impact pricing. Bulk orders usually receive tiered discounts.

Q: Why would I need a square root scale instead of linear on a differential pressure gauge?

A: Square root scales directly display flow rates proportional to √ΔP, saving calculation steps required with linear pressure scales. This provides immediate percentage-of-flow readings, improving operational efficiency in flow measurement applications like HVAC balancing or pump monitoring.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025