lip . 07, 2024 04:40 Back to list

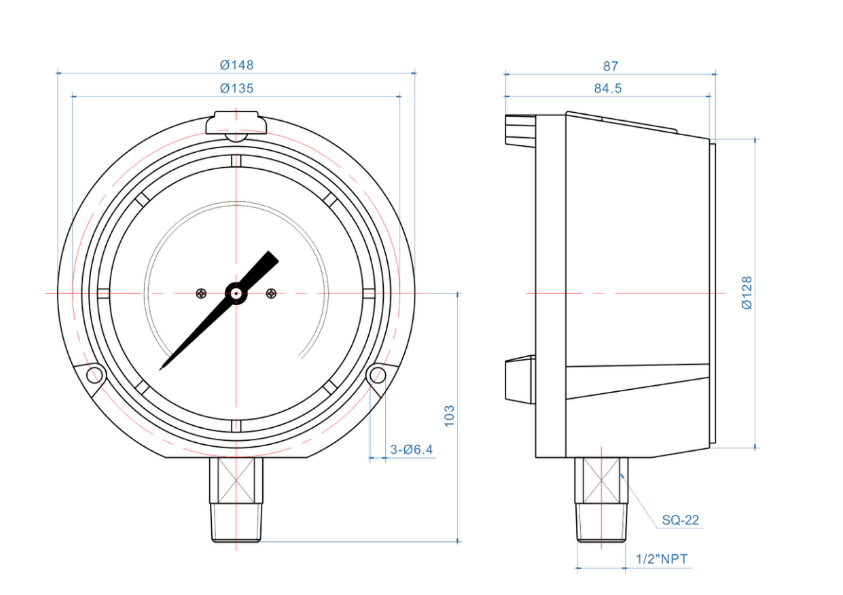

JAH differential pressure gauge measures pressure in pounds per square inch.

Differential pressure gauges are an essential tool in many industries, including oil and gas, chemical processing, and water treatment plants, to monitor the pressure difference between two points in a system. One popular type of differential pressure gauge is the Jah differential pressure gauge, which measures pressure in pounds per square inch (psi).

The Jah differential pressure gauge is a reliable and accurate device that is used to monitor the pressure difference between two points in a pipeline or system. It is commonly used in applications where precise pressure measurements are required, such as in HVAC systems, power plants, and manufacturing facilities. The gauge operates by comparing the pressure at two different points and displaying the difference in psi on a dial or digital readout.

One of the key advantages of using a Jah differential pressure gauge is its ability to provide real-time monitoring of pressure variations in a system. This allows operators to quickly identify any potential issues, such as leaks or blockages, before they escalate into more significant problems. By continuously monitoring the pressure difference between two points, operators can ensure that the system is operating within safe and efficient parameters.

In addition to monitoring pressure differentials, Jah differential pressure gauges can also be used to calculate flow rates within a system. By measuring the pressure drop across a restriction, such as a valve or filter, operators can determine the rate at which fluid is flowing through the system By measuring the pressure drop across a restriction, such as a valve or filter, operators can determine the rate at which fluid is flowing through the system By measuring the pressure drop across a restriction, such as a valve or filter, operators can determine the rate at which fluid is flowing through the system By measuring the pressure drop across a restriction, such as a valve or filter, operators can determine the rate at which fluid is flowing through the system

By measuring the pressure drop across a restriction, such as a valve or filter, operators can determine the rate at which fluid is flowing through the system By measuring the pressure drop across a restriction, such as a valve or filter, operators can determine the rate at which fluid is flowing through the system jah differential pressure gauge psi. This information is crucial for maintaining optimal system performance and maximizing efficiency.

Another benefit of using a Jah differential pressure gauge is its durability and reliability. These gauges are built to withstand harsh industrial environments and are designed to provide accurate readings even in extreme conditions. The robust construction of the gauge ensures that it can continue to perform effectively for years to come, making it a cost-effective investment for any industrial operation.

In conclusion, the Jah differential pressure gauge is a valuable tool for monitoring pressure differentials in a wide range of industrial applications. Its ability to provide accurate and real-time measurements, along with its durability and reliability, make it an essential instrument for maintaining the efficiency and safety of industrial systems. Whether used in oil and gas production, chemical processing, or water treatment plants, the Jah differential pressure gauge is an indispensable device for ensuring optimal system performance.

jah differential pressure gauge psi. This information is crucial for maintaining optimal system performance and maximizing efficiency.

Another benefit of using a Jah differential pressure gauge is its durability and reliability. These gauges are built to withstand harsh industrial environments and are designed to provide accurate readings even in extreme conditions. The robust construction of the gauge ensures that it can continue to perform effectively for years to come, making it a cost-effective investment for any industrial operation.

In conclusion, the Jah differential pressure gauge is a valuable tool for monitoring pressure differentials in a wide range of industrial applications. Its ability to provide accurate and real-time measurements, along with its durability and reliability, make it an essential instrument for maintaining the efficiency and safety of industrial systems. Whether used in oil and gas production, chemical processing, or water treatment plants, the Jah differential pressure gauge is an indispensable device for ensuring optimal system performance.

By measuring the pressure drop across a restriction, such as a valve or filter, operators can determine the rate at which fluid is flowing through the system By measuring the pressure drop across a restriction, such as a valve or filter, operators can determine the rate at which fluid is flowing through the system

By measuring the pressure drop across a restriction, such as a valve or filter, operators can determine the rate at which fluid is flowing through the system By measuring the pressure drop across a restriction, such as a valve or filter, operators can determine the rate at which fluid is flowing through the system jah differential pressure gauge psi. This information is crucial for maintaining optimal system performance and maximizing efficiency.

Another benefit of using a Jah differential pressure gauge is its durability and reliability. These gauges are built to withstand harsh industrial environments and are designed to provide accurate readings even in extreme conditions. The robust construction of the gauge ensures that it can continue to perform effectively for years to come, making it a cost-effective investment for any industrial operation.

In conclusion, the Jah differential pressure gauge is a valuable tool for monitoring pressure differentials in a wide range of industrial applications. Its ability to provide accurate and real-time measurements, along with its durability and reliability, make it an essential instrument for maintaining the efficiency and safety of industrial systems. Whether used in oil and gas production, chemical processing, or water treatment plants, the Jah differential pressure gauge is an indispensable device for ensuring optimal system performance.

jah differential pressure gauge psi. This information is crucial for maintaining optimal system performance and maximizing efficiency.

Another benefit of using a Jah differential pressure gauge is its durability and reliability. These gauges are built to withstand harsh industrial environments and are designed to provide accurate readings even in extreme conditions. The robust construction of the gauge ensures that it can continue to perform effectively for years to come, making it a cost-effective investment for any industrial operation.

In conclusion, the Jah differential pressure gauge is a valuable tool for monitoring pressure differentials in a wide range of industrial applications. Its ability to provide accurate and real-time measurements, along with its durability and reliability, make it an essential instrument for maintaining the efficiency and safety of industrial systems. Whether used in oil and gas production, chemical processing, or water treatment plants, the Jah differential pressure gauge is an indispensable device for ensuring optimal system performance. Share

Latest news

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025