dec . 04, 2024 09:14 Back to list

odm pressure gauge components

Understanding ODM Pressure Gauge Components

Pressure gauges are essential instruments used in various industries to measure the pressure of gases or liquids within a system. Among the various types of pressure gauges, the ODM (Oil-Dynamic Measurement) pressure gauge is particularly noteworthy due to its unique design and operational efficiency. This article will delve into the components that make up ODM pressure gauges, their functionality, and applications.

Key Components of ODM Pressure Gauges

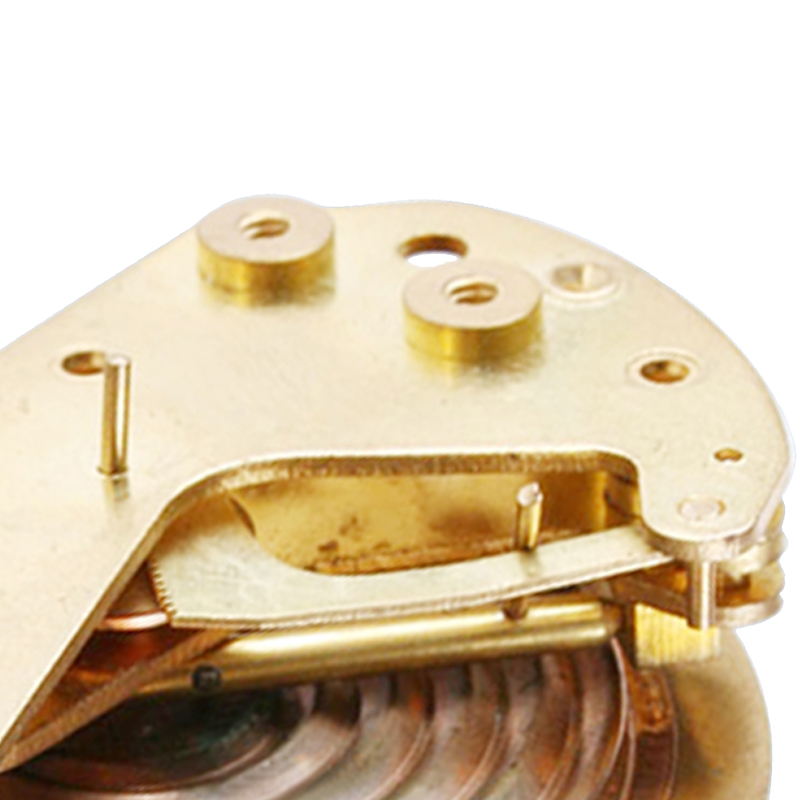

1. Bourdon Tube The Bourdon tube is often considered the heart of the pressure gauge. This curved, metal tube is sealed at one end and connected to the pipeline at the other. As pressure increases, the tube tends to straighten out. This mechanical movement is subsequently translated into a rotational movement, which moves the gauge pointer across a dial, indicating the pressure level.

2. Movement Mechanism The movement mechanism converts the linear movement of the Bourdon tube into a rotational movement that drives the pointer on the gauge. This system typically consists of a gear train that amplifies the small movement of the Bourdon tube into a much larger rotation of the pointer.

3. Dial The dial is the part of the gauge that displays the pressure measurement. It is calibrated with numerical markings, often in various units such as psi, bar, or kPa, making it easy for users to read the pressure levels. The dial's visibility and design are crucial for quick readings in a dynamic environment.

4. Pointer The pointer is attached to the movement mechanism and indicates the corresponding pressure value on the dial. A well-designed pointer allows for precise measurements and easy reading, contributing to the overall effectiveness of the pressure gauge.

5. Case and Window The case encases all internal components, protecting them from environmental factors such as dust, moisture, and mechanical impacts. The window, usually made of glass or plastic, provides visibility to the dial while ensuring protection against external elements.

odm pressure gauge components

6. Connection fittings Connection fittings are essential for attaching the pressure gauge to the pipeline or system being monitored. They must be compatible with the specific pressure application and resistant to the medium being measured, ensuring leak-free operation.

7. Damping Mechanism In many ODM pressure gauges, especially those used in high-vibration environments, a damping mechanism is employed. This can be in the form of a liquid fill (like glycerin or silicone oil) that reduces pointer bounce, allowing for more stable and accurate readings.

8. Calibration Mechanism Accurate pressure readings are crucial in industrial applications. A calibration mechanism allows for the adjustment of the gauge to ensure precise measurements. Regular calibration helps maintain the reliability and accuracy of the instrument.

Applications of ODM Pressure Gauges

ODM pressure gauges find diverse applications across various sectors. In the oil and gas industry, these gauges are used to monitor pressure levels in pipelines and tanks, ensuring safe operation and preventing over-pressure situations. The gauge's robust design allows it to withstand harsh environments, making it an integral component in this sector.

Additionally, in the chemical processing industry, ODM pressure gauges are vital for measuring the pressure of reaction vessels, ensuring that processes operate within safe limits. In HVAC systems, these gauges help monitor air pressures to maintain optimal functioning and energy efficiency.

Conclusion

The ODM pressure gauge is a critical tool for various industries, providing accurate pressure measurements that are essential for safety and efficiency. Understanding the different components of these gauges can help users appreciate their importance and ensure proper maintenance and calibration for optimal performance. Whether used in oil fields, chemical plants, or HVAC systems, ODM pressure gauges stand as reliable instruments contributing to operational success in a wide range of applications.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025