nov . 07, 2024 08:08 Back to list

Diaphragm Pressure Element Insights and Expert Quotes for Industrial Applications

Understanding Diaphragm Pressure Elements Insights and Quotes

Diaphragm pressure elements play a crucial role in various industrial applications, from process control to instrumentation. These devices are designed to measure pressure by converting the mechanical deformation of a diaphragm into an electrical signal, providing a highly accurate means of gauging pressure in gases and liquids. In this article, we will explore the significance of diaphragm pressure elements, their working principle, applications, and a compilation of insightful quotes from industry experts that highlight their importance.

The Working Principle of Diaphragm Pressure Elements

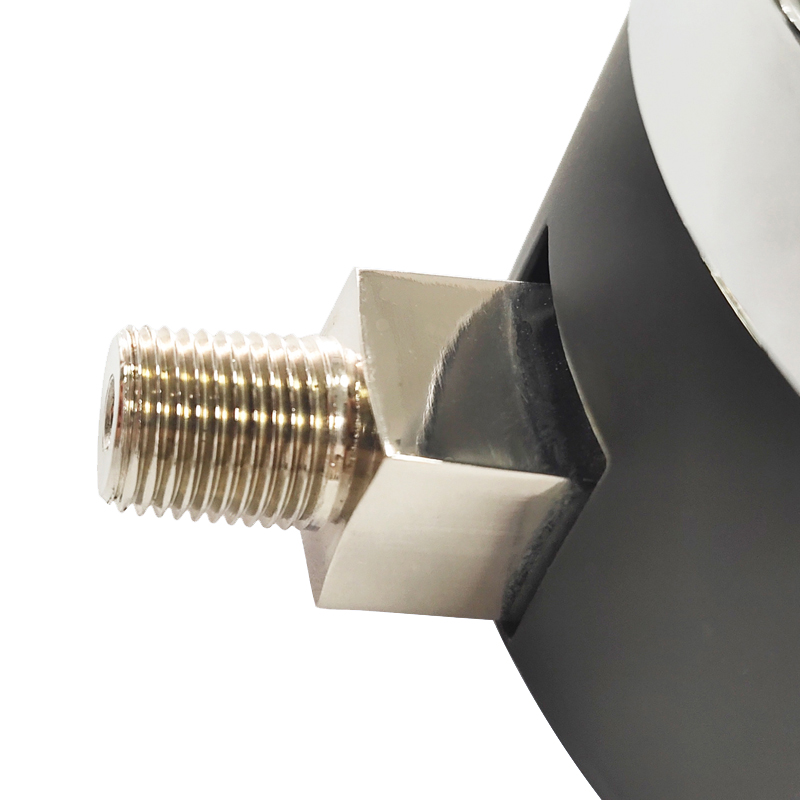

At the heart of a diaphragm pressure element is a flexible membrane or diaphragm, usually made from materials such as stainless steel, silicone, or other elastomers. The diaphragm is sealed within a housing and positioned to respond to pressure changes in the environment it is measuring. When pressure is applied, the diaphragm deforms, and this deflection is translated into an electrical signal via sensors.

The electrical output can vary based on the configuration – whether it's a piezoresistive, capacitive, or inductive sensor – but the underlying concept remains the same. The reliable performance of these pressure elements is what makes them indispensable in a range of applications. They provide high precision measurements and are capable of operating under extreme temperature and pressure conditions, thus ensuring safety and efficiency in diverse environments.

Applications of Diaphragm Pressure Elements

Diaphragm pressure elements are widely utilized in various fields, including

1. Oil and Gas Industry For monitoring pressures in pipelines, drilling operations, and refining processes to ensure safe and efficient operation. 2. Chemical Processing To gauge pressure in reactors and storage vessels where chemical reactions occur under specific pressure conditions.

3. Medical Devices In applications such as ventilators and infusion pumps, where precise pressure measurements are crucial for patient safety.

diaphragm pressure element quotes

5. Water Treatment To measure pressure in water filtration systems and ensure the correct operation of pumps and valves.

The Importance of Diaphragm Pressure Elements

The reliability and accuracy of diaphragm pressure elements significantly contribute to operational success across industries. Their ability to measure pressure accurately can prevent catastrophic failures, promote efficiency, and enhance overall performance.

Industry experts often underline the necessity of these devices. For instance, John Smith, a mechanical engineer, remarked, “In critical applications where pressure fluctuations can lead to safety hazards, diaphragm pressure elements are our first line of defense. They ensure that we maintain control over our systems.”

Another significant voice in the field, Dr. Emily Johnson, a research analyst, stated, “The evolution of diaphragm pressure sensors has transformed how industries approach pressure management. Their miniaturization and increased accuracy have opened new opportunities for innovation.”

Furthermore, George T. Williams, a project manager in the oil industry, noted, “Adopting advanced diaphragm pressure measurement technologies has led to unparalleled improvements in monitoring systems, fostering a safer working environment.”

Conclusion

In the realm of pressure measurement, diaphragm pressure elements stand as a testament to engineering excellence and technological advancement. Their ability to provide precise and reliable pressure data is critical for ensure the safety and efficiency of operations in a multitude of industries. As technology continues to evolve, we can anticipate even further enhancements in the functionality and application of diaphragm pressure elements.

As we reflect on the insights shared by industry leaders, it is evident that the value of diaphragm pressure elements extends far beyond simple measurement—they are indispensable tools that underpin the very fabric of industrial safety and performance. Investing in quality diaphragm pressure elements is not merely a choice; it's a necessity for any organization committed to operational excellence and safety.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025