Sep . 21, 2024 19:48 Back to list

wika differential pressure gauge 733.14 product

Understanding the Wika Differential Pressure Gauge 733.14

The Wika Differential Pressure Gauge 733.14 is a vital instrument used in various industrial applications for measuring the pressure difference between two points in a system. This device is renowned for its accuracy, reliability, and durability, making it an essential tool for engineers and technicians in fields such as HVAC, water treatment, and various manufacturing processes.

Design and Features

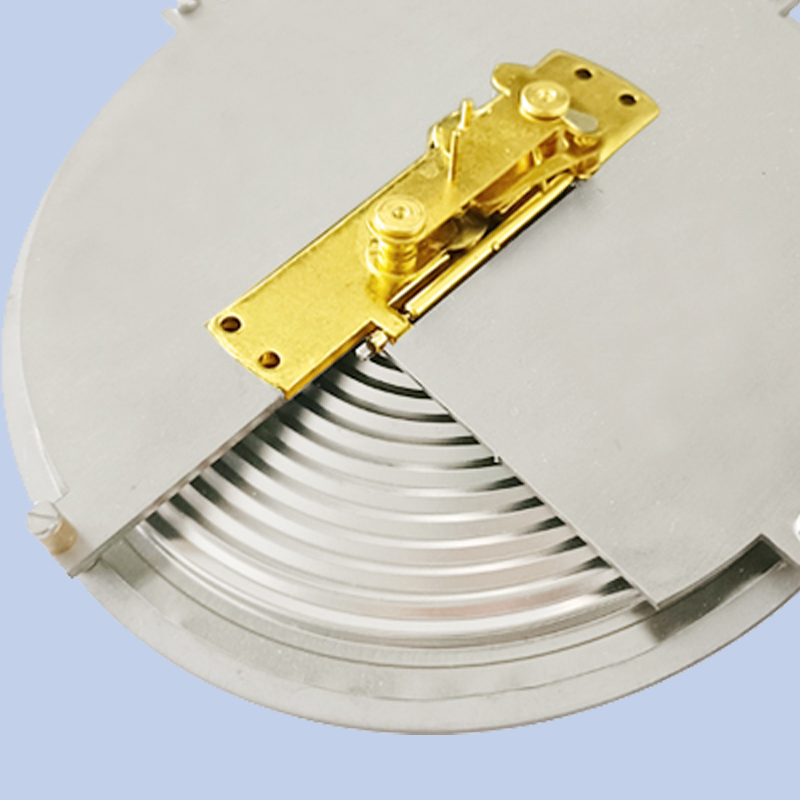

The Wika 733.14 is designed with user-friendliness in mind. Its robust stainless steel construction ensures resistance to corrosive environments, which is critical in many industrial settings. With a clear, easy-to-read dial, operators can quickly and accurately assess pressure readings. The gauge features a range of pressure scales, allowing it to measure both positive and negative pressures, making it versatile for various applications.

One of the notable features of the 733.14 is its precision movement, which helps in delivering accurate readings even in fluctuating conditions. Furthermore, this differential gauge is equipped with a silicone-damped movement, which minimizes needle oscillation and enhances the readability of the dial. This is particularly beneficial in environments where pressure changes rapidly, as it offers a stable and clear indication of pressure differences.

Applications

The Wika Differential Pressure Gauge 733.14 is widely used in numerous applications. In HVAC systems, it is used to monitor filter differentials, ensuring that filters are operating efficiently and alerting maintenance personnel when they require replacement. In wastewater treatment facilities, it measures pressure drops across various stages of the treatment process, helping to maintain optimal operations and efficiency.

wika differential pressure gauge 733.14 product

Additionally, the gauge plays a crucial role in monitoring flow rates in piping systems. By assessing the pressure drop across pipes, engineers can determine whether there are any blockages or issues that need addressing, thereby preventing potential system failures or costly downtimes.

Installation and Maintenance

Installing the Wika 733.14 is straightforward, as it can be mounted in various orientations to fit the requirements of the specific application. Users should ensure that the gauge is calibrated correctly to match the system's specifications, as accurate calibration is crucial for reliable readings.

Regular maintenance of the gauge involves periodic checks to ensure that it remains in proper working order. While the rugged construction of the Wika 733.14 minimizes the need for frequent maintenance, operators should inspect for signs of wear or damage. This not only prolongs the life of the gauge but also ensures consistent and accurate performance over time.

Conclusion

In conclusion, the Wika Differential Pressure Gauge 733.14 is an essential instrument that combines durability, accuracy, and versatility. Its design and robust features make it suitable for a wide range of industrial applications. By effectively measuring pressure differences, this gauge aids in monitoring performance, enhancing efficiency, and preventing system failures. Investing in a reliable differential pressure gauge like the Wika 733.14 is crucial for any industry that prioritizes precision and operational excellence.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025