Nov . 12, 2024 22:03 Back to list

wika differential pressure gauge 700.04 company

Understanding WIKA Differential Pressure Gauge 700.04

In the world of industrial measurement, precision and reliability are paramount. One product that exemplifies these qualities is the WIKA Differential Pressure Gauge 700.04. This particular gauge is engineered to measure the difference in pressure between two points within a system, making it an essential tool in various applications, including HVAC systems, chemical processing, and water treatment facilities.

Design and Features

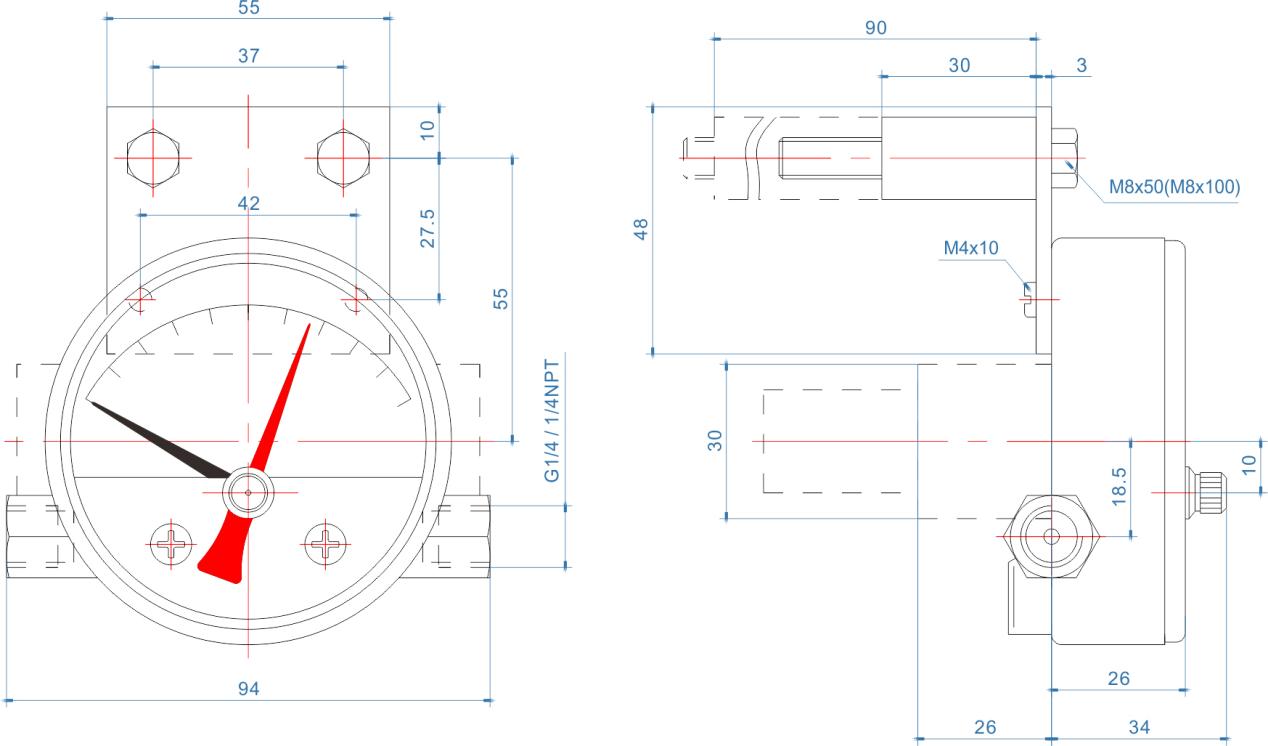

The WIKA 700.04 differential pressure gauge features a robust design suited for harsh environments. With a stainless steel casing, it offers excellent resistance to corrosion and can withstand high-pressure scenarios. Its dial features a clear, easy-to-read scale, which is crucial for operators to quickly assess operational conditions. The design also includes a safety glass cover that protects the gauge face from damage while ensuring that readings remain unobstructed.

One of the standout features of the WIKA 700.04 is its high accuracy. The gauge is typically calibrated to provide results within a specific range, ensuring that users can rely on the measurements for critical applications. This accuracy is achieved through meticulous manufacturing processes and adherence to strict quality control standards.

Operating Principle

The working principle of a differential pressure gauge, including the WIKA 700.04, is relatively straightforward. It consists of two pressure ports one for the high-pressure side and one for the low-pressure side. The gauge compares the pressure difference between these ports and translates this into a readable value on the display.

This functionality is essential in many scenarios. For instance, in HVAC systems, the gauge helps monitor the pressure drop across filters, indicating when they need cleaning or replacement. Similarly, in chemical processes, it can monitor the pressure differentials across reactors or separators, ensuring optimal operating conditions.

wika differential pressure gauge 700.04 company

Applications

The versatility of the WIKA Differential Pressure Gauge 700.04 allows it to be employed across numerous industries. In the oil and gas sector, it ensures safe operations by monitoring pressure levels in pipelines. In water treatment facilities, it helps control filtration systems by providing real-time data on filter performance. Additionally, in critical medical environments, these gauges can monitor pressure changes in equipment, contributing to patient safety.

Moreover, the WIKA 700.04 is used extensively in laboratory settings for experiments requiring precise pressure measurements. Its accuracy and reliability make it a preferred choice among professionals in scientific research and development.

Installation and Maintenance

Installing the WIKA Differential Pressure Gauge 700.04 is a straightforward process, though it must be done following best practices to ensure accurate readings. It is crucial to install the gauge in a location where it can capture the necessary pressure differentials without obstruction. Furthermore, periodic calibration and maintenance are recommended to ensure the gauge remains accurate over time. This is particularly important in critical applications where even minor inaccuracies can lead to significant consequences.

Users should also be aware of the environmental factors affecting gauge performance. Extreme temperatures or exposure to aggressive chemicals can compromise the integrity of the gauge. WIKA provides guidelines for the proper use and care of its gauges to enhance longevity and accuracy.

Conclusion

The WIKA Differential Pressure Gauge 700.04 is a vital instrument for anyone needing precise pressure measurements in their operations. With its robust construction, high accuracy, and versatility, it meets the demands of various industries and applications. By understanding its design, function, and proper maintenance, users can maximize its effectiveness, ensuring safe and efficient system operations. Whether in industrial processes, HVAC systems, or laboratory environments, the WIKA 700.04 remains a reliable choice for differential pressure measurement.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025