Nov . 18, 2024 06:33 Back to list

Understanding the Benefits and Applications of Wika Differential Pressure Gauges

Understanding the WIKA Differential Pressure Gauge

In various industrial applications, accurate pressure measurements are critical to ensuring safety, efficiency, and reliability. One such instrument that plays a pivotal role in monitoring pressure levels is the differential pressure gauge, particularly the WIKA differential pressure gauge, known for its precision and robustness. This article will delve into the features, applications, and significance of WIKA differential pressure gauges, providing a comprehensive understanding of why they are a preferred choice in many sectors.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument used to measure the difference in pressure between two points in a system. This measurement is essential in various processes, such as filtration, flow measurement, and level measurements in tanks. WIKA, a renowned manufacturer in this field, designs these gauges to provide reliable and accurate results in various demanding situations.

Key Features of WIKA Differential Pressure Gauges

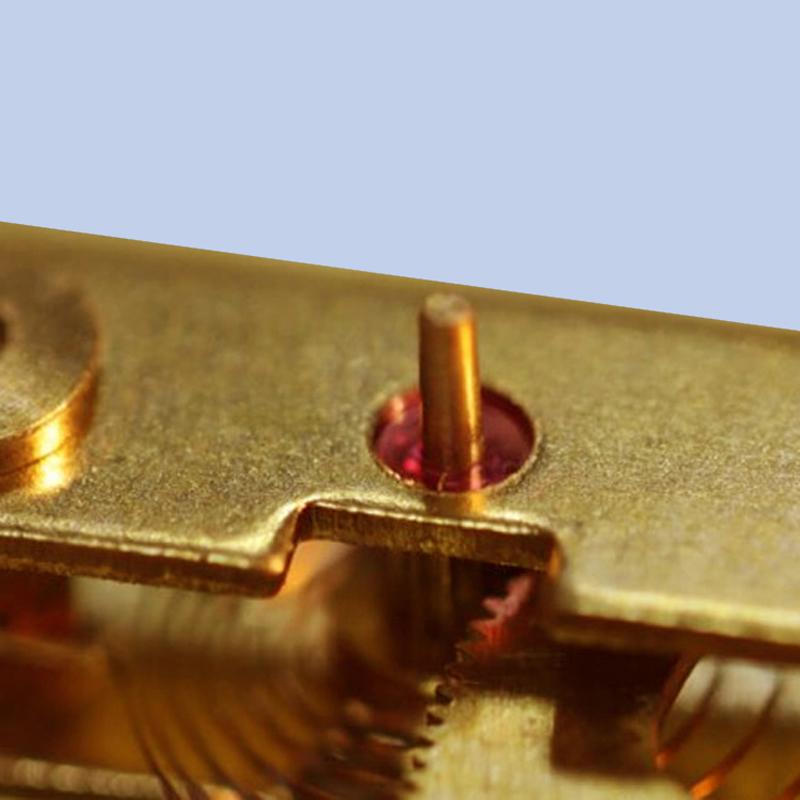

1. High Precision WIKA differential pressure gauges are engineered for high accuracy, often featuring an accuracy class of up to 0.25%. This precision is vital in applications where even slight pressure variations can lead to significant operational issues.

2. Robust Construction Designed to withstand harsh working environments, WIKA's gauges feature durable materials that can endure various temperatures and pressures. This resilience ensures longevity and reduces the need for frequent replacements.

3. Wide Range of Applications WIKA differential pressure gauges are versatile, suitable for various industries, including oil and gas, water treatment, HVAC, and food processing. The ability to measure small pressure differences makes them ideal for monitoring filter conditions, airflow, and tank levels.

4. User-Friendly Design Many WIKA gauges come equipped with easy-to-read dials and display options that simplify the monitoring process for operators. This user-centric design minimizes the risk of errors in reading and interpreting pressure levels.

wika differential pressure gauge 4 quotes

5. Customizable Options WIKA understands that different applications may require specific configurations. Therefore, they offer a range of types, sizes, and features, including electrical outputs for integration with control systems, allowing for tailored solutions that meet unique customer needs.

Applications of WIKA Differential Pressure Gauges

The applications of differential pressure gauges are numerous and varied

- Filtration Monitoring In filtration systems, monitoring the pressure drop across a filter is crucial for determining when it needs to be cleaned or replaced. A WIKA differential pressure gauge accurately indicates when the pressure reaches a critical point, ensuring process efficiency.

- Flow Measurement In many industries, differential pressure gauges are used to calculate flow rates. By measuring the pressure difference across a flow meter, these gauges help determine the overall flow of liquids or gases within a system.

- Level Measurement In tanks and other containers, differential pressure gauges can be used to measure liquid levels by calculating the pressure exerted by the liquid column. This method is not only reliable but also crucial in avoiding overflows and potential hazards.

- Leak Detection WIKA differential pressure gauges can also serve as tools for identifying leaks in systems. A sudden change in the differential pressure reading might indicate a compromise in the system, prompting immediate investigation.

Conclusion

The WIKA differential pressure gauge stands out as a vital instrument in various industrial applications, combining precision, robustness, and versatility. By accurately measuring pressure differences, these gauges contribute to the safe and efficient operation of numerous processes. As industries continue to evolve, the need for reliable and accurate pressure measurement solutions will only grow. WIKA's commitment to quality and innovation ensures that their differential pressure gauges will remain at the forefront of this essential field, helping businesses maintain operational integrity and enhance safety standards. For those looking to invest in high-quality pressure measurement tools, WIKA offers an array of options tailored to meet diverse needs, solidifying its reputation as a leader in the market.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025