Dec . 11, 2024 00:53 Back to list

Manufacturers of Diaphragm Pressure Gauges for Industrial Applications and Solutions

Understanding the Role of Diaphragm Pressure Gauges in Industry

Diaphragm pressure gauges are essential instruments used in various industries to measure the pressure of gases and liquids. Their reliability, accuracy, and ability to withstand harsh environments make them a preferred choice for many applications. This article delves into the features of diaphragm pressure gauges, their working principle, and the advantages offered by factories specializing in their production.

The Working Principle of Diaphragm Pressure Gauges

At the core of a diaphragm pressure gauge is a flexible diaphragm, typically made from materials such as stainless steel or elastomers, which is designed to deflect under pressure. When the pressure of the fluid or gas acting on the diaphragm changes, the diaphragm deforms. This deformation is then translated into a mechanical movement, which drives a pointer on a calibrated scale, providing a direct reading of the pressure.

The diaphragm's design allows for accurate readings over a wide range of pressure levels, from vacuum to high pressures. Furthermore, the simplicity of the mechanical components means that these gauges require minimal maintenance and can operate effectively in various environments, including those with vibrations, temperature fluctuations, and corrosive substances.

Key Features and Applications

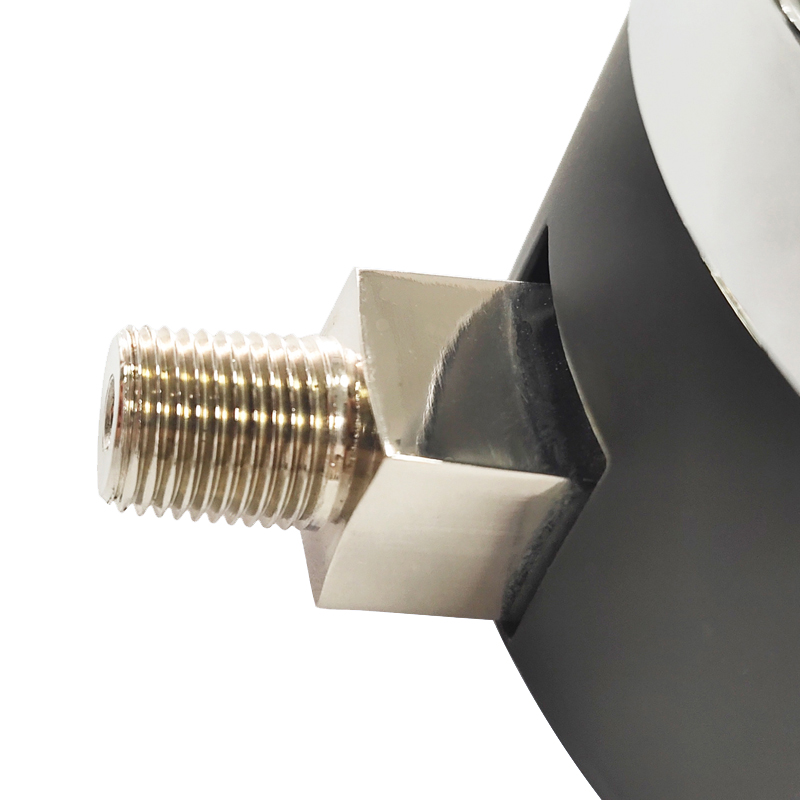

Diaphragm pressure gauges are characterized by their rugged construction, safety features, and versatility. Many factories that produce these instruments use advanced materials and manufacturing techniques to enhance their durability and resistance to wear and tear. They often feature corrosion-resistant casings, shockproof designs, and options for various pressure ranges, making them suitable for applications in sectors such as oil and gas, chemical processing, food and beverage, and pharmaceuticals.

wika diaphragm pressure gauge factories

Moreover, diaphragm gauges can be designed with different types of connections and configurations. For example, some may have electrical contacts for automatic monitoring systems, while others may include additional features like liquid-fill for enhanced stability in fluctuating temperatures and pressures. This adaptability makes diaphragm pressure gauges invaluable in process industries, where precise pressure measurement is critical for safety and efficiency.

Advantages of Specialized Factories

Choosing to source diaphragm pressure gauges from specialized manufacturers comes with several benefits. These factories often possess extensive expertise and experience in the production of such instruments, ensuring high quality and reliability in their products. They typically implement strict quality control measures and adhere to international standards, providing customers with confidence in their purchases.

Additionally, many factories offer customization options. This means that they can produce gauges with specific ranges, sizes, and connections tailored to the unique requirements of the client. Such customization capabilities are essential for industries with specialized processes or equipment that require bespoke solutions.

Furthermore, reputable manufacturers often provide excellent after-sales support. This includes assistance with installation, maintenance, and troubleshooting, which can significantly enhance the user experience. By building long-term relationships with their clients, these factories contribute to the operational efficiency and safety of their customers’ systems.

Conclusion

In summary, diaphragm pressure gauges play a crucial role in industries that require accurate and reliable pressure measurement. Their unique design and versatility make them suitable for a wide range of applications, from basic pressure monitoring to complex industrial processes. By choosing to work with specialized factories, companies can ensure that they receive high-quality products developed with industry knowledge and expertise. As technology advances, these gauges will continue to evolve, meeting the increasing demands for accuracy and durability in the world of industrial pressure measurement.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025