Dec . 09, 2024 21:50 Back to list

Differential Pressure Gauge Solutions and Products for Various Applications

Understanding the Importance of Differential Pressure Gauges

In various industrial applications, maintaining optimal operational conditions is crucial for efficiency and safety. One of the essential instruments for monitoring these conditions is the differential pressure gauge (DP gauge). This device plays a significant role in various sectors, including HVAC, process industries, water treatment, and many others. In this article, we will explore the functions, types, and applications of differential pressure gauges, as well as their significance in maintaining system integrity.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points in a system. It is particularly useful for detecting the flow of fluids, monitoring filter conditions, and ensuring that pressure levels remain within specified limits. The gauge typically has two inlet ports; one measures the pressure at a reference point, while the other measures pressure at the point of interest. The difference between these two readings is displayed on a dial or digital readout, providing critical information about the system’s performance.

Types of Differential Pressure Gauges

Differential pressure gauges come in various designs tailored to specific applications. Some common types include

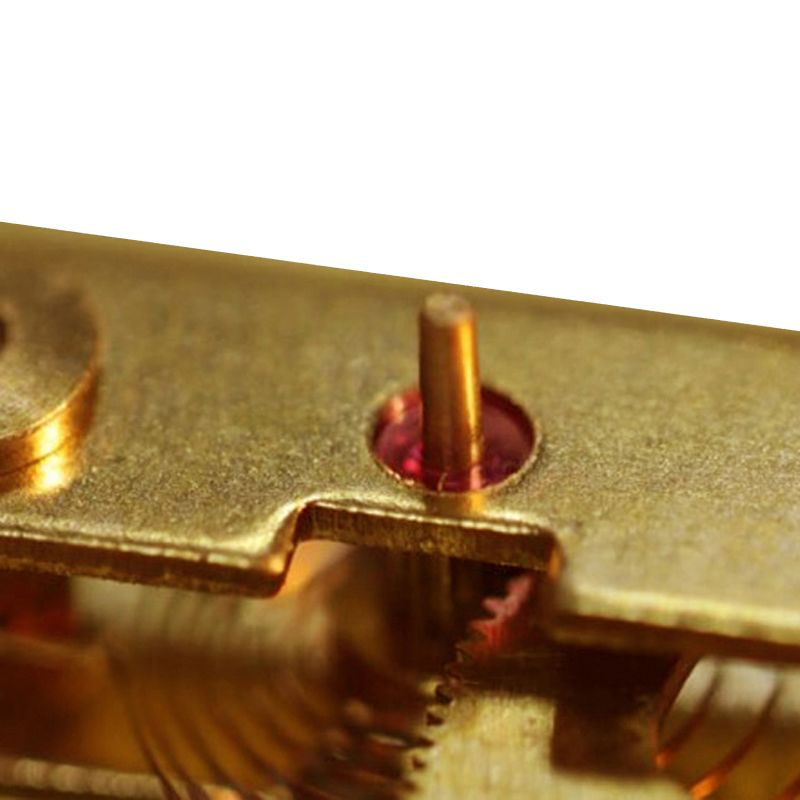

1. Mechanical Differential Pressure Gauges These traditional gauges utilize a diaphragm or bellows to sense pressure differences. The displacement of the diaphragm translates into a measurable pressure difference shown on a dial. They are reliable and widely used in numerous applications.

2. Digital Differential Pressure Gauges These devices use electronic sensors to measure pressure differences. They often provide more precise readings and can include features like data logging, alarms, and remote monitoring capabilities. Digital gauges are increasingly favored for their accuracy and ease of integration with automated systems.

3. Capacitive Differential Pressure Gauges Utilizing a capacitor to measure pressure differences, these gauges are prized for their high precision and stability over varying temperatures and environmental conditions.

wika 4 differential pressure gauge products

Applications of Differential Pressure Gauges

Differential pressure gauges are employed across various industries due to their versatility and reliability. Key applications include

- HVAC Systems In heating, ventilation, and air conditioning systems, DP gauges monitor airflow across filters and fans. This monitoring helps ensure proper airflow and filter conditions, leading to energy efficiency and enhanced indoor air quality.

- Process Industries In oil, gas, and chemical processing plants, these gauges play a crucial role in monitoring liquid and gas flow rates. They detect changes that could indicate blockages or equipment failure, allowing for timely maintenance and preventing costly downtime.

- Water Treatment Facilities In water treatment plants, differential pressure gauges monitor the pressure across filtration systems, helping to maintain optimal performance and water quality.

- Pharmaceutical Manufacturing In this highly regulated environment, DP gauges are vital for ensuring that processes meet strict safety and quality standards.

Importance of Differential Pressure Gauges

The significance of differential pressure gauges cannot be overstated. By providing real-time data on pressure differentials, these instruments enable operators to monitor system performance actively. Identifying trends or anomalies in pressure readings can indicate maintenance needs, inform process adjustments, and enhance safety protocols. Ultimately, accurate measurement leads to improved efficiency, lower operational costs, and extended equipment life.

Conclusion

In summary, differential pressure gauges are essential instruments in a wide range of industries, delivering critical information that helps ensure efficient and safe operations. Whether mechanical or digital, these gauges provide vital insights into the pressure conditions of systems, facilitating effective management and maintenance. As industries continue to evolve and innovate, the role of differential pressure gauges will remain pivotal in supporting operational excellence and compliance with safety standards.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025