Dec . 04, 2024 17:36 Back to list

Exploring 732.51 Differential Pressure Gauge Specifications and Manufacturers

Understanding the Wika 4 Differential Pressure Gauge 732.51 A Manufacturer’s Insight

The Wika 4 Differential Pressure Gauge 732.51 is a critical instrument widely used in various industrial applications. It plays a significant role in measuring the difference in pressure between two points, providing essential data for process control and monitoring systems. This article seeks to offer insights into the specifications, applications, and advantages of the Wika 732.51 gauge, emphasizing why it stands out among its competitors.

Key Specifications

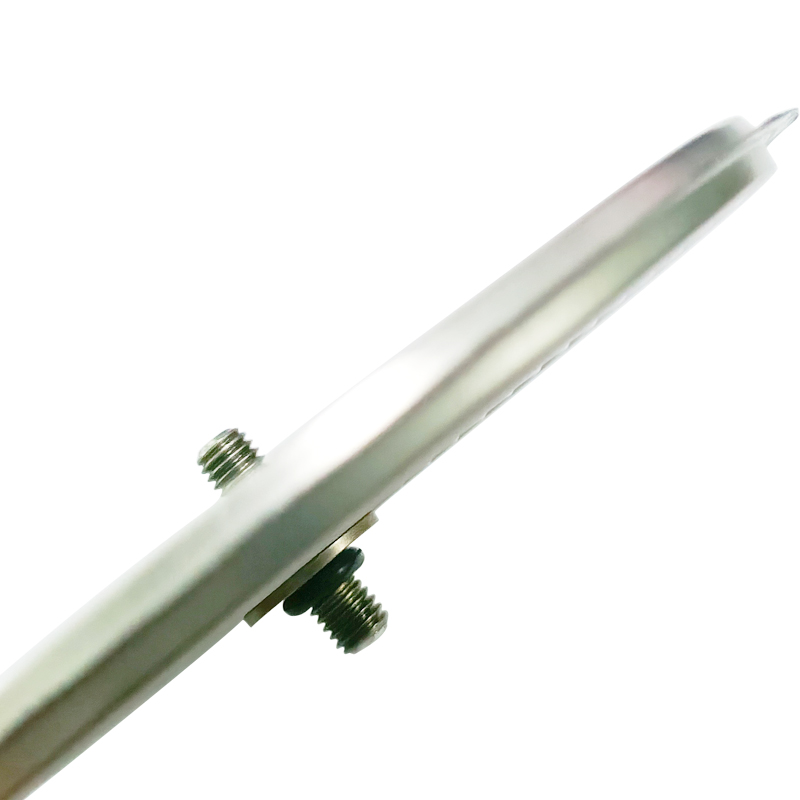

The Wika 732.51 differential pressure gauge is engineered for precision and durability. With a measurement range that can be customized to meet specific industrial needs, it typically operates within ranges of ±0.1 mbar to ±600 mbar. The device features a robust stainless steel housing which ensures its reliability in harsh environments, making it suitable for use in industries such as chemical processing, water treatment, and HVAC systems.

One of the notable features of the Wika 732.51 is its diaphragm sensing element. This design enhances the gauge's ability to accurately measure low differential pressures. Additionally, the gauge offers various output signal options, including analog and digital formats, enabling seamless integration with existing monitoring systems. The clarity of its dial and the availability of different connection types further enhance its usability, ensuring that the gauge can be easily installed and operated.

Applications in Industry

The versatility of the Wika 732.51 differential pressure gauge allows it to be employed in various applications. For instance, in the HVAC industry, it is utilized to monitor air filters' pressure drop, ensuring optimal airflow and energy efficiency. In the pharmaceutical sector, it plays a crucial role in maintaining sterile conditions by monitoring the pressure differences in cleanroom environments.

wika 4 differential pressure gauge 732.51 manufacturers

Furthermore, in the oil and gas sector, the gauge is vital for measuring pressure drops across pipelines and equipment, helping to prevent system failures. Its capability to withstand fluctuations in temperature and pressure further solidifies its essential role in safeguarding equipment and processes across various industries.

Advantages of the Wika 732.51

The Wika 732.51 differential pressure gauge offers several advantages that contribute to its popularity among users. First and foremost is its accuracy; the gauge is designed to minimize errors and provide reliable readings, essential for critical applications. This precision reduces the risk of operational interruptions and enhances overall efficiency.

Another advantage is its robustness. The stainless steel construction, along with its optimized design, allows the 732.51 to perform well even in challenging conditions. This durability means users can rely on the gauge for long-term performance without frequent replacements, leading to cost savings.

Ease of installation and compatibility with various systems also make the Wika 732.51 a preferred choice. Its user-friendly design allows technicians to install and calibrate the gauge quickly, minimizing downtime during installation. Additionally, the gauge's adaptability ensures compatibility with a wide range of industrial systems, providing flexibility for users.

Conclusion

In conclusion, the Wika 4 Differential Pressure Gauge 732.51 stands out as a premier choice for industrial applications requiring precise and reliable pressure measurements. With its robust design, versatility, and ease of use, it meets the demands of various sectors, including HVAC, pharmaceuticals, and oil and gas. The combination of high-quality materials, innovative engineering, and a user-friendly interface makes the Wika 732.51 an indispensable tool for professionals seeking to enhance operational efficiency and safety. As industries continue to evolve, the need for reliable measurement instruments like the Wika 732.51 will undoubtedly remain a top priority.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025