Sep . 09, 2024 05:29 Back to list

wika diaphragm type pressure gauge jah

Understanding the Diaphragm-Type Pressure Gauge

Pressure measurement is a fundamental aspect of many industrial processes, ensuring safety and efficiency across various applications. One of the commonly used instruments for this purpose is the diaphragm-type pressure gauge. This article will explore the working principle, advantages, and applications of this essential device.

What is a Diaphragm-Type Pressure Gauge?

A diaphragm-type pressure gauge is a mechanical instrument designed to measure the pressure of gases or liquids. Unlike other types of pressure gauges, the diaphragm gauge uses a flexible membrane or diaphragm that responds to pressure changes. As the external pressure varies, the diaphragm deforms, causing a connected mechanism to translate this movement into a readable pressure measurement.

Working Principle

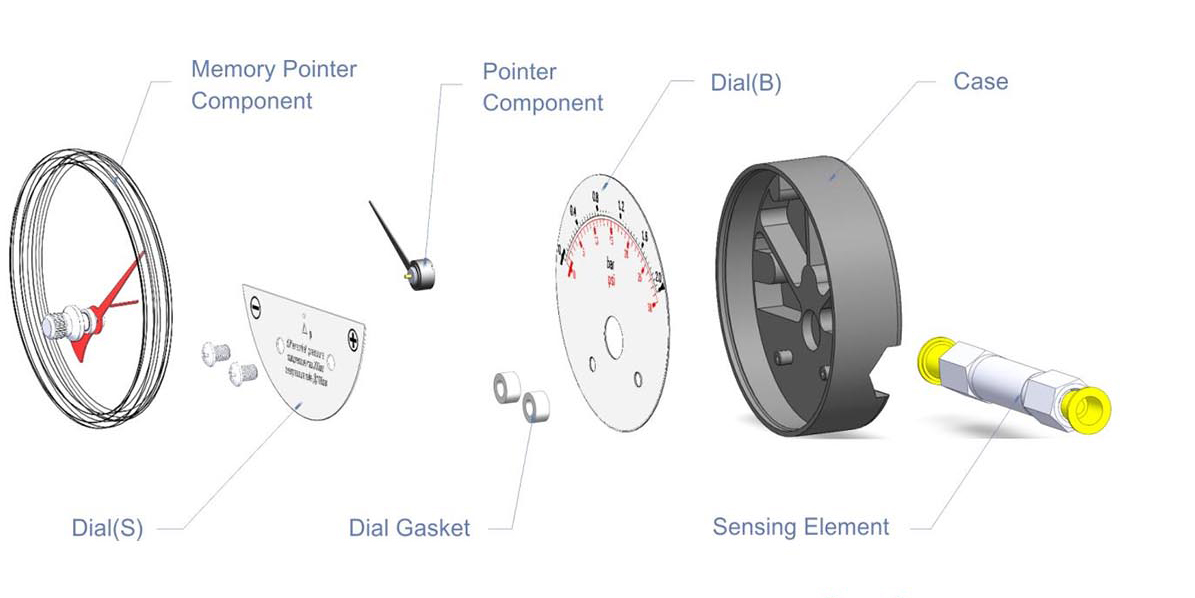

The central component of the diaphragm-type pressure gauge is the diaphragm, which is typically made from elastic materials such as stainless steel or silicone. When pressure is applied, the diaphragm bends, creating a displacement that is proportional to the pressure being measured. This mechanical movement is transmitted through a linkage assembly to a pointer, which displays the pressure on a calibrated dial.

The diaphragm's ability to flex makes this type of gauge highly sensitive, providing accurate readings even for small pressure variations. Some designs may also include additional features like electric contacts for alarms or data logging capabilities.

Advantages of Diaphragm-Type Pressure Gauges

1. High Accuracy Diaphragm-type pressure gauges are known for their precision, making them suitable for applications requiring accurate and reliable pressure readings. 2. Wide Pressure Range These gauges can measure a broad range of pressures, from low vacuum to high pressure, making them versatile in various settings.

wika diaphragm type pressure gauge jah

3. Robustness The diaphragm design is inherently resistant to vibrations and shocks, which enhances the durability of the gauge in harsh environments.

4. Low Maintenance Due to their simple mechanical design, diaphragm gauges often require minimal maintenance, reducing operational costs.

5. Fluid Compatibility These gauges can be designed to handle corrosive or viscous fluids, thanks to the choice of materials used in constructing the diaphragm and housing.

Applications

Diaphragm-type pressure gauges can be found in a multitude of applications across different industries, including

- Chemical Processing Used to monitor pressure in reactors or pipelines handling corrosive substances. - Water and Wastewater Treatment Employed in pumps and filtration systems to ensure proper pressure levels. - Food and Beverage Industry Used to measure pressure in sterilization processes and during the handling of ingredients. - Pharmaceuticals Critical for ensuring the smooth operation of equipment involved in drug production.

Conclusion

Diaphragm-type pressure gauges are essential instruments that play a vital role in monitoring and controlling pressure across various industrial applications. Their accuracy, durability, and versatility make them a preferred choice among engineers and operators in many sectors. As industries continue to advance, the importance of reliable pressure measurement tools like diaphragm gauges is more crucial than ever, ensuring processes run safely and efficiently.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025