Nov . 05, 2024 02:27 Back to list

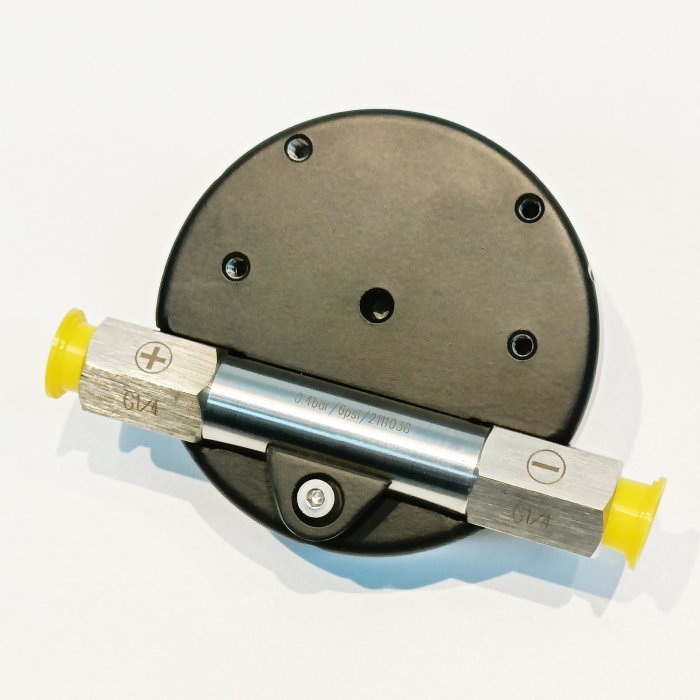

wholesale wika differential pressure gauge 732.51

Understanding the Wholesale WIKA Differential Pressure Gauge 732.51

In the realm of industrial measurement and automation, accurate monitoring of pressure is crucial for operational efficiency and safety. Among various instruments designed for this purpose, the WIKA Differential Pressure Gauge 732.51 stands out for its reliability, precision, and robust construction. This article delves into the features, applications, and advantages of the WIKA 732.51 differential pressure gauge, making it a preferred choice for many industries.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument used to measure the difference in pressure between two points within a system. It is essential in various applications, such as monitoring filters, measuring flow, and controlling processes. The WIKA 732.51 gauge provides accurate readings, allowing operators to make informed decisions based on real-time data.

Key Features of the WIKA Differential Pressure Gauge 732.51

The WIKA 732.51 is designed with several defining features

1. High Precision Measurement The gauge is known for its high accuracy, typically within ±1.6% of full scale. This precision is vital in processes where slight variations in pressure can significantly impact performance.

2. Robust Design Constructed from high-quality materials, the WIKA 732.51 withstands demanding environments. Its stainless steel casing protects against corrosion, while the robust diaphragm ensures durability against pressure fluctuations.

3. Range of Applications This gauge is suitable for liquid and gas applications, making it versatile across various industries such as oil and gas, chemical processing, and HVAC.

4. Wide Pressure Range The WIKA 732.51 offers a wide selection of pressure ranges, typically from 0 to 25 bar or higher, catering to diverse measurement needs.

5. Easy Installation and Maintenance Designed for user convenience, the gauge can be easily installed and maintained, minimizing downtime and additional labor costs.

Applications of the WIKA 732.51

wholesale wika differential pressure gauge 732.51

The WIKA 732.51 differential pressure gauge finds applications in various sectors

- Filtration Systems In filtration processes, monitoring differential pressure helps to determine the condition of filters. A significant drop in differential pressure often indicates clogging, necessitating maintenance or replacement.

- HVAC Systems In heating, ventilation, and air conditioning systems, the gauge is used to measure the pressure drop across coils and filters, ensuring optimal airflow and energy efficiency.

- Process Manufacturing In chemical and food processing industries, maintaining pressure differences is crucial for ensuring product quality and safety. The WIKA 732.51 helps monitor these parameters accurately.

- Water and Wastewater Treatment In municipal water treatment plants, differential pressure gauges are used to monitor pressure across treatment systems, ensuring effective operation and compliance with regulatory standards.

Advantages of Using WIKA 732.51

Choosing the WIKA 732.51 comes with numerous advantages

- Reliability WIKA is a trusted name in pressure measurement technology. The gauge’s reputation for reliability ensures that operators can trust the readings for critical operations.

- Cost-Effectiveness Given its robustness and low maintenance needs, the WIKA 732.51 offers a cost-effective solution over its lifespan, delivering excellent value for investment.

- Technical Support and Service WIKA provides comprehensive technical support and service, ensuring that customers can resolve any issues quickly, thereby minimizing downtime.

Conclusion

In conclusion, the WIKA Differential Pressure Gauge 732.51 is a versatile, durable, and precise instrument ideal for a wide range of industrial applications. Its robust design, easy installation, and high accuracy make it a crucial component in maintaining safe and efficient operations. As industries increasingly rely on accurate data for process optimization, the significance of quality instrumentation like the WIKA 732.51 cannot be overstated. Investing in such reliable measurement tools is a step towards achieving operational excellence and ensuring compliance with industry standards.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025