Nov . 27, 2024 11:54 Back to list

Wholesale Differential Pressure Gauges for Vacuum Applications and Industrial Use

Understanding Wholesale Vacuum Differential Pressure Gauges

In industrial applications, precise measurement of pressure is critical for ensuring optimal performance and safety. One of the essential tools for such measurements is the vacuum differential pressure gauge. This article explores the concept, operation, and applications of wholesale vacuum differential pressure gauges, shedding light on their significance in various sectors.

What is a Vacuum Differential Pressure Gauge?

A vacuum differential pressure gauge is a device designed to measure the pressure difference between two points, one of which is typically below atmospheric pressure (a vacuum). These gauges are widely used in various applications where monitoring of low pressure is crucial. They can provide precise readings of pressure differentials to help engineers and technicians maintain the desired conditions for processes involving gases or liquids.

How Does It Work?

The operation of a vacuum differential pressure gauge is based on the principle of pressure measurement through a sensing element. The two pressure measurement points are connected to the gauge—one for the vacuum side and the other for the reference side, which may be atmospheric or another pressure level. The difference in these pressures is translated into a readable output, often displayed in units such as inches of mercury (inHg) or Pascals.

There are several types of vacuum differential pressure gauges, including

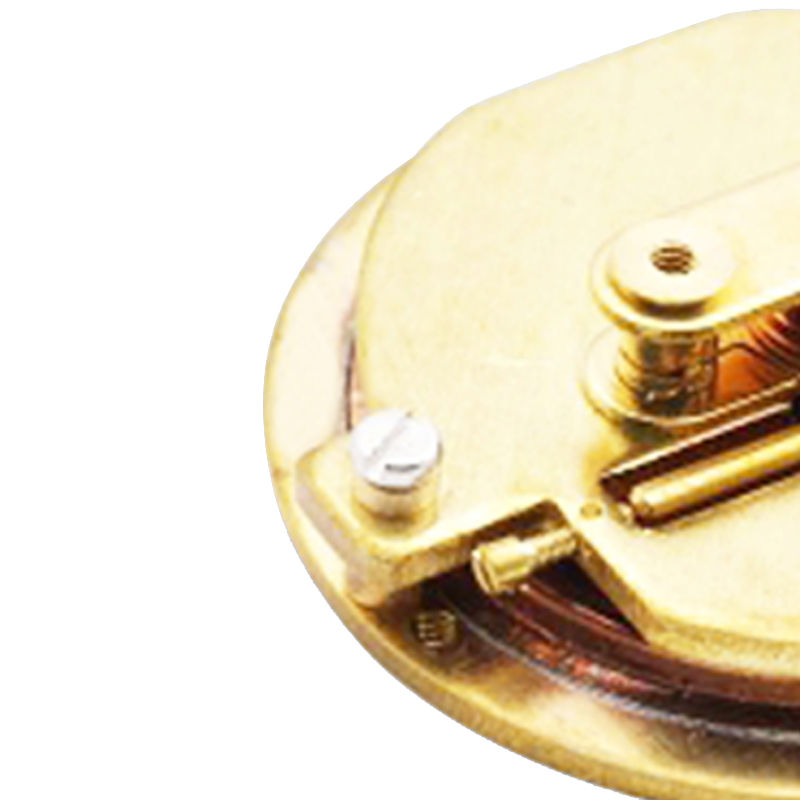

1. Bourdon Tube Gauges These utilize a curved, sealed tube that straightens out as pressure increases. The movement of the tube is mechanically converted into a dial reading. 2. Diaphragm Gauges These consist of a flexible diaphragm that moves in response to pressure changes. The displacement of the diaphragm is measured and converted into a pressure reading.

3. Capacitance Gauges These employ the principles of capacitance to detect pressure changes, providing high accuracy and sensitivity.

4. Piezoelectric Gauges Utilizing piezoelectric materials, these gauges convert pressure into an electrical signal, allowing for digital output and analysis.

wholesale vacuum differential pressure gauge

Applications

Vacuum differential pressure gauges find a wide range of applications across different industries

- Manufacturing In processes such as coating, packaging, and drying, maintaining specific vacuum levels is crucial. Differential pressure gauges help monitor and adjust these levels to ensure quality control. - Pharmaceuticals In the pharmaceutical industry, vacuum systems are used in various applications, including freeze-drying and sterile processing. Accurate measurements ensure product safety and efficacy.

- Food Processing Vacuum systems are prevalent in food preservation methods, including vacuum sealing and dehydration. Differential pressure gauges help ensure optimal conditions for preserving food quality while preventing spoilage.

- HVAC Systems In heating, ventilation, and air conditioning systems, vacuum differential pressure gauges are used to monitor duct systems, filter performance, and system efficiency.

Wholesale Considerations

When purchasing vacuum differential pressure gauges wholesale, several considerations come into play. Quality and reliability are paramount; therefore, working with reputable manufacturers is vital. It is also essential to consider the type of gauge that best suits specific application needs. Factors such as temperature range, pressure capabilities, and the environment in which the gauge will operate should be evaluated.

Additionally, price is an important factor in wholesale purchases. While cost-effectiveness is desirable, the reliability of the gauge should not be compromised. Investing in quality instruments can lead to reduced downtime and maintenance costs in the long run.

Conclusion

In conclusion, wholesale vacuum differential pressure gauges are indispensable tools in many industries where pressure measurement is critical. Understanding their operation, applications, and factors to consider when purchasing them wholesale can significantly enhance industrial processes. These gauges not only contribute to product quality and safety but also ensure that operations run smoothly and efficiently in an ever-evolving industrial landscape. Manufacturers and buyers alike should prioritize quality and reliability to make informed decisions that benefit their operations.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025