Dec . 03, 2024 19:21 Back to list

Wholesale Sealed Diaphragm Pressure Gauge for Accurate Measurement Solutions

Understanding Wholesale Sealed Diaphragm Pressure Gauges

In industrial applications, accurate measurement of pressure is crucial. One of the most reliable tools for this purpose is the sealed diaphragm pressure gauge. These gauges are widely used due to their robustness and ability to deliver precise readings, even in challenging environments. In this article, we will explore the features, advantages, applications, and wholesale considerations of sealed diaphragm pressure gauges.

What is a Sealed Diaphragm Pressure Gauge?

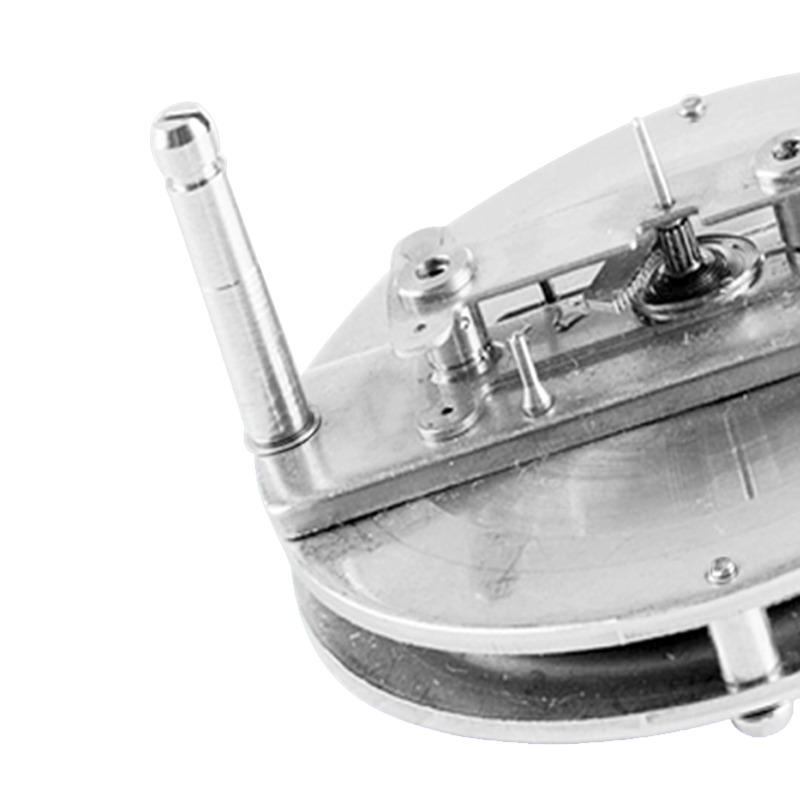

A sealed diaphragm pressure gauge features a flexible diaphragm that responds to pressure changes. As pressure is applied to one side of the diaphragm, it deflects, causing a pointer attached to a mechanical linkage to move over a calibrated scale. The key feature that distinguishes sealed diaphragm gauges is their ability to prevent contamination and protect the internal mechanisms from adverse environments.

Key Features

1. Protection from Contaminants The sealed design prevents moisture, dust, and dirt from entering the gauge, providing a longer service life and consistent performance.

2. High Sensitivity The diaphragm's flexibility allows for high sensitivity to pressure changes, making these gauges suitable for low-pressure measurements as well.

3. Robust Construction Often made from durable materials like stainless steel or brass, sealed diaphragm pressure gauges can withstand harsh conditions, including extreme temperatures and corrosive substances.

4. Wide Range of Applications These gauges can measure a variety of pressures, facilitating their use in multiple sectors such as manufacturing, oil and gas, pharmaceuticals, and food processing.

Advantages of Sealed Diaphragm Pressure Gauges

1. Reliability The sealed construction minimizes the risk of failure due to leaks or contamination, ensuring long-term reliability and accuracy.

2. Ease of Maintenance Since contaminants do not enter the gauge, maintenance is generally simpler and less frequent, reducing downtime in industrial settings.

4. Cost-Effectiveness While the initial investment may be higher compared to non-sealed gauges, the durability and reduced maintenance needs result in overall cost savings.

wholesale sealed diaphragm pressure gauge

Applications

Sealed diaphragm pressure gauges find applications in numerous industries

- Oil and Gas Measuring pressure in pipelines and processing plants, ensuring safety and efficiency. - Pharmaceuticals Monitoring process pressures in drug manufacturing to maintain stringent quality control. - Food and Beverage Ensuring precise pressure measurements in production processes to comply with health regulations. - HVAC Systems Monitoring pressure in heating, ventilation, and air conditioning systems for optimal performance.

Wholesale Considerations

When considering wholesale purchases of sealed diaphragm pressure gauges, several factors should be taken into account

1. Quality Standards Look for gauges manufactured to recognized standards (such as ISO or ANSI) to ensure reliability and accuracy.

2. Supplier Reputation Collaborating with reputable suppliers known for their quality products and customer support is essential. Reviews and recommendations can guide this decision.

3. Customization Options Depending on the specific needs of your application, inquire about customizable options, such as gauge size, dial type, or pressure range.

4. Pricing and Bulk Discounts Investigate pricing structures and the possibility of bulk discounts. Many suppliers offer reduced prices for larger orders, which can significantly enhance profitability.

5. Lead Times Assess the lead times for delivery, especially if you have urgent demands. Reliable suppliers should provide clear timelines for when you can expect to receive your order.

6. Warranty and Support A solid warranty and availability of technical support from the supplier can safeguard your investment and assist with any issues that may arise post-purchase.

Conclusion

Sealed diaphragm pressure gauges are indispensable tools in various industries where precise pressure measurement is critical. Their reliable construction, protection against contaminants, and versatility make them a preferred choice among professionals. With the right considerations in wholesale procurement, businesses can ensure they gain the maximum benefit from these essential instruments. Whether in oil and gas, pharmaceuticals, or food processing, the right sealed diaphragm pressure gauge can significantly enhance operational efficiency and safety.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025