Nov . 04, 2024 10:23 Back to list

Wholesale Murphy Differential Pressure Gauge for Accurate Pressure Measurement Solutions

Wholesale Murphy Differential Pressure Gauge A Comprehensive Overview

In the realm of industrial measurement and monitoring, differential pressure gauges are vital tools that ensure the seamless operation of various processes across multiple sectors. Among the brands that have established a reputation for reliability and precision is Murphy, with its range of wholesale differential pressure gauges being particularly noteworthy. Understanding the features, applications, and benefits of these gauges can significantly assist industries in optimizing their operations.

Understanding Differential Pressure Gauges

A differential pressure gauge measures the difference in pressure between two points within a system. This capability is crucial for monitoring processes in various applications, including HVAC systems, fluid dynamics, and even in the oil and gas sector. Typically, these gauges consist of two pressure inlets—a high-pressure and a low-pressure port—and a mechanism that translates the difference into a readable format, often displayed on a dial or a digital screen.

Murphy Differential Pressure Gauges An Overview

Murphy's differential pressure gauges are designed with precision engineering to withstand the rigors of industrial environments. They are known for their durable construction, which often includes materials resistant to corrosion and harsh chemicals. This makes them suitable for a variety of applications, whether in water treatment facilities, chemical processing plants, or HVAC systems.

One of the hallmarks of Murphy differential pressure gauges is their accuracy. These instruments can provide precise readings, which are crucial for maintaining optimal operating conditions and ensuring safety in processes. The gauges also feature a range of measuring scales, allowing users to select the most appropriate range for their specific applications.

Applications of Murphy Differential Pressure Gauges

The versatility of Murphy differential pressure gauges makes them suitable for a multitude of applications

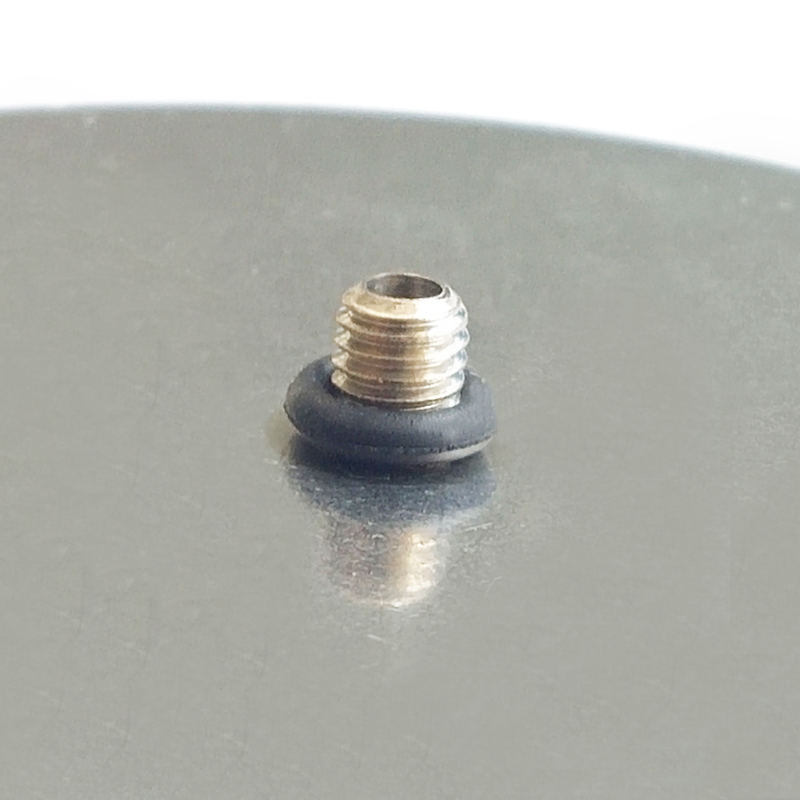

wholesale murphy differential pressure gauge

1. HVAC Systems In heating, ventilation, and air conditioning systems, differential pressure gauges are utilized to monitor airflow and pressure drops across filters and coils. This monitoring is essential for maintaining air quality and system efficiency.

2. Fluid Dynamics In industries involving the flow of liquids and gases, these gauges help monitor pressure drops across pumps and valves, ensuring the efficiency of fluid transport and identifying potential blockages.

3. Water Treatment In water treatment facilities, differential pressure gauges are essential for monitoring filter performance, alerting operators when maintenance is required to prevent system failures.

4. Oil and Gas Industry The gauges assist in monitoring pressure differences in various stages of oil and gas extraction and processing, ensuring systems operate within safe parameters.

Benefits of Wholesale Purchase

Opting for wholesale purchase of Murphy differential pressure gauges comes with distinct advantages. Bulk purchasing typically leads to lower per-unit costs, making it a cost-effective solution for large-scale operations. Additionally, buying in bulk ensures consistent quality and compatibility across all gauges, simplifying maintenance and inventory management.

Moreover, wholesale suppliers often offer customization options, allowing businesses to select specific features or scales that align with their operational requirements. This flexibility can lead to enhanced performance and satisfaction, as customers receive products tailored to their unique needs.

Conclusion

In summary, Murphy differential pressure gauges are essential instruments for a variety of industrial applications. Their accuracy, durability, and versatility make them invaluable for maintaining optimal process conditions. By considering wholesale purchases, industries can benefit from cost savings and the assurance of quality and performance. As industries continue to evolve, reliable measurement tools like Murphy's differential pressure gauges will play a pivotal role in driving efficiency and safety across various sectors.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025