Dec . 17, 2024 03:12 Back to list

wholesale low pressure diaphragm pressure gauges

Wholesale Low Pressure Diaphragm Pressure Gauges Understanding Their Importance in Various Industries

Low pressure diaphragm pressure gauges are essential instruments used in various industries to measure and monitor the pressure of liquids and gases. These gauges provide accurate readings, ensuring that systems operate efficiently and safely. In this article, we will explore the significance of wholesale low pressure diaphragm pressure gauges, their working mechanism, applications, and the benefits they offer to different sectors.

What is a Diaphragm Pressure Gauge?

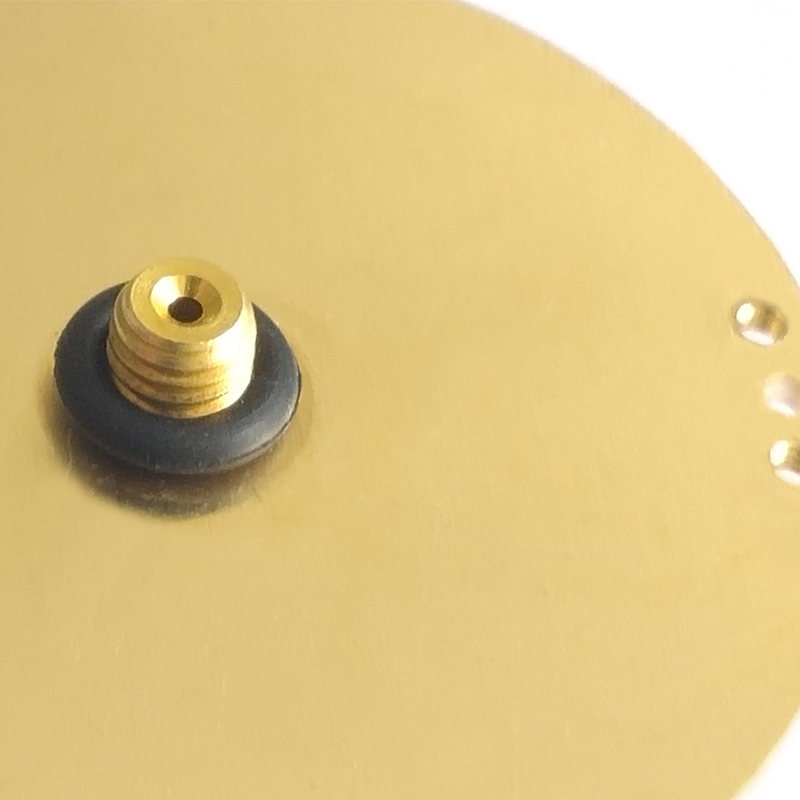

A diaphragm pressure gauge is a type of mechanical pressure measuring instrument that utilizes a flexible membrane or diaphragm to sense pressure changes. When pressure is applied to the diaphragm, it deflects, causing a connected needle to move along a calibrated scale. This movement provides a direct reading of the pressure inside a system.

Low pressure gauges, specifically, are designed to measure pressures typically below 15 psi (pounds per square inch). They are commonly used in applications where precision is crucial, and the pressures involved are relatively low.

Importance in Various Industries

1. Process Industries Industries such as chemical manufacturing, food and beverage, and pharmaceuticals rely heavily on low pressure diaphragm gauges. They use these gauges to monitor fluid pressure in pipelines and reactors, ensuring that processes operate within safe and optimal pressure ranges.

2. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, low pressure gauges help in measuring the pressure of refrigerants and gases. Accurate pressure readings are vital for system efficiency, energy consumption, and maintaining proper environmental conditions.

3. Water Treatment In water treatment facilities, diaphragm pressure gauges are utilized to monitor pressure on filtration systems and pumps. They help ensure that processes run efficiently, preventing breakdowns and maintaining water quality.

4. Renewable Energy In the growing field of renewable energy, specifically in biogas and solar thermal systems, these gauges measure pressures at various stages of production. Monitoring helps optimize the production process and maintains operational integrity.

Features of Low Pressure Diaphragm Gauges

When considering wholesale low pressure diaphragm pressure gauges, certain features should be taken into account

wholesale low pressure diaphragm pressure gauges

- Material Composition Gauges should be constructed from durable materials that resist corrosion, especially in chemical applications. Common materials include stainless steel and brass.

- Accuracy and Calibration High accuracy is paramount. Quality manufacturers calibrate their gauges to ensure precise readings. Look for options with accuracy ratings of ±1% or better.

- Size and Range Gauges come in various sizes and pressure ranges. Selecting the correct range and size according to your specific application can enhance performance and reliability.

- Connection Types Different industries may require various connection types for their gauges. Standard connections include threaded, flanged, and sanitary fittings.

Benefits of Wholesale Purchasing

Purchasing low pressure diaphragm pressure gauges wholesale presents multiple advantages

1. Cost Savings Buying in bulk often comes with significant discounts, which is beneficial for companies needing multiple gauges or replacement parts.

2. Consistency in Quality Wholesalers can provide consistent product quality, ensuring that all gauges meet the same standards and specifications.

3. Availability of Components Wholesalers usually offer a comprehensive range of gauges along with accessories and replacement parts, simplifying the procurement process.

4. Expert Support Reputable wholesalers often provide technical support and guidance on selecting the right gauge for specific applications, which can save time and reduce errors.

Conclusion

Low pressure diaphragm pressure gauges are crucial instruments across numerous industries, enhancing safety, process efficiency, and product quality. Understanding their operation, features, and applications can aid businesses in selecting the appropriate gauges for their needs. Purchasing these instruments wholesale not only ensures cost-effectiveness but also guarantees a high standard of quality and support. As industries evolve, the importance of accurate pressure monitoring will continue to grow, making these gauges indispensable tools for operational success.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025