Nov . 08, 2024 16:44 Back to list

wholesale liquid filled differential pressure gauge

Understanding Wholesale Liquid-Filled Differential Pressure Gauges

In various industrial applications, the precise measurement of pressure differences is crucial for ensuring system efficiency and safety. One of the key instruments used for this purpose is the liquid-filled differential pressure gauge. This article provides an overview of how these gauges operate, their benefits, and their applications, particularly in wholesale markets.

What is a Differential Pressure Gauge?

A differential pressure gauge is a device designed to measure the difference in pressure between two points in a system. Unlike standard pressure gauges that measure a single pressure point, differential gauges provide insight into pressure variations, which is essential in various applications, including HVAC systems, water treatment plants, and chemical processing.

These gauges can be filled with liquid, such as glycerin or silicone oil, which helps dampen vibrations and protects the internal mechanisms from shock. The liquid filling enhances the gauge's durability and accuracy in dynamic environments, making it particularly valuable in industrial settings.

How Do Liquid-Filled Differential Pressure Gauges Work?

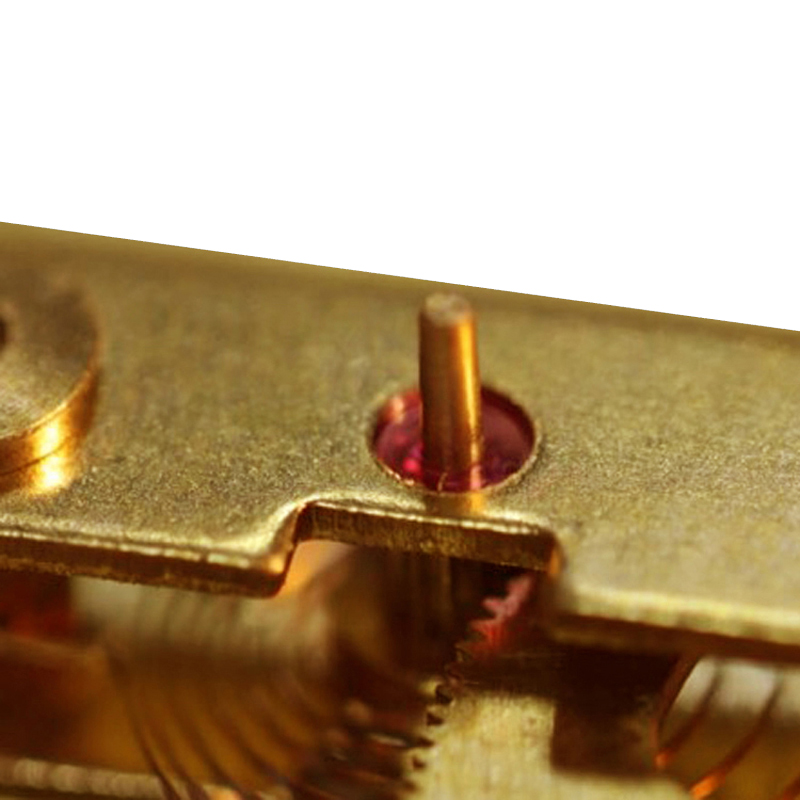

The core principle behind a liquid-filled differential pressure gauge is the balance between two pressures. The gauge comprises two pressure ports connected to the system where measurements are taken. As pressure changes occur, these pressures act on a diaphragm or a Bourdon tube inside the gauge, causing it to deflect. The resultant movement is translated into a readable measurement, usually displayed on a dial.

Liquid filling serves several purposes it minimizes the risk of corrosion within the gauge, it absorbs shock from sudden pressure changes, and it provides a stable reading in fluctuating environments. As a result, liquid-filled differential pressure gauges tend to offer improved performance and longevity compared to their dry counterparts.

Benefits of Liquid-Filled Differential Pressure Gauges

1. Accuracy and Stability The liquid filling dampens vibrations and pulsations, leading to more accurate and stable readings, especially in turbulent environments.

wholesale liquid filled differential pressure gauge

2. Longer Life Span The protective liquid ensures that internal components are shielded from environmental factors, corrosion, and shock, resulting in a longer lifespan for the gauge.

3. Wide Temperature Range Liquid-filled gauges are often capable of operating within a wider temperature range, making them suitable for diverse applications.

4. Minimal Maintenance Due to their robust design and protective liquid, these gauges typically require less maintenance and can remain functional over extended periods.

5. Versatility Liquid-filled differential pressure gauges can be used in a variety of applications, from monitoring air filters in HVAC systems to measuring liquid levels in tanks.

Applications in Wholesale Markets

In the wholesale market, liquid-filled differential pressure gauges are in high demand across numerous sectors. Industries such as oil and gas, water treatment, food and beverage, and pharmaceuticals utilize these gauges for monitoring processes where pressure differentials are critical.

Wholesalers often stock a range of differential pressure gauges tailored to the specific needs of various industries. They provide businesses with the opportunity to obtain reliable measuring instruments at competitive prices, ensuring they can maintain operational efficiency and safety standards.

Conclusion

Liquid-filled differential pressure gauges are vital tools in modern industrial applications. Their ability to provide accurate, stable, and reliable measurements makes them indispensable for maintaining the efficiency and safety of various processes. With their growing importance in the wholesale market, businesses are increasingly recognizing the value these gauges bring to their operations. Understanding and leveraging these instruments can significantly enhance productivity and system reliability in today’s fast-paced industrial environments.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025