Nov . 14, 2024 09:31 Back to list

wholesale explain diaphragm pressure gauge

Understanding Diaphragm Pressure Gauges in Wholesale Applications

Diaphragm pressure gauges are essential instruments used in various industries to measure the pressure of gases and liquids. Their reliability, accuracy, and versatility make them popular choices for both industrial applications and laboratory settings. This article will delve into the workings, advantages, and wholesale considerations of diaphragm pressure gauges.

What is a Diaphragm Pressure Gauge?

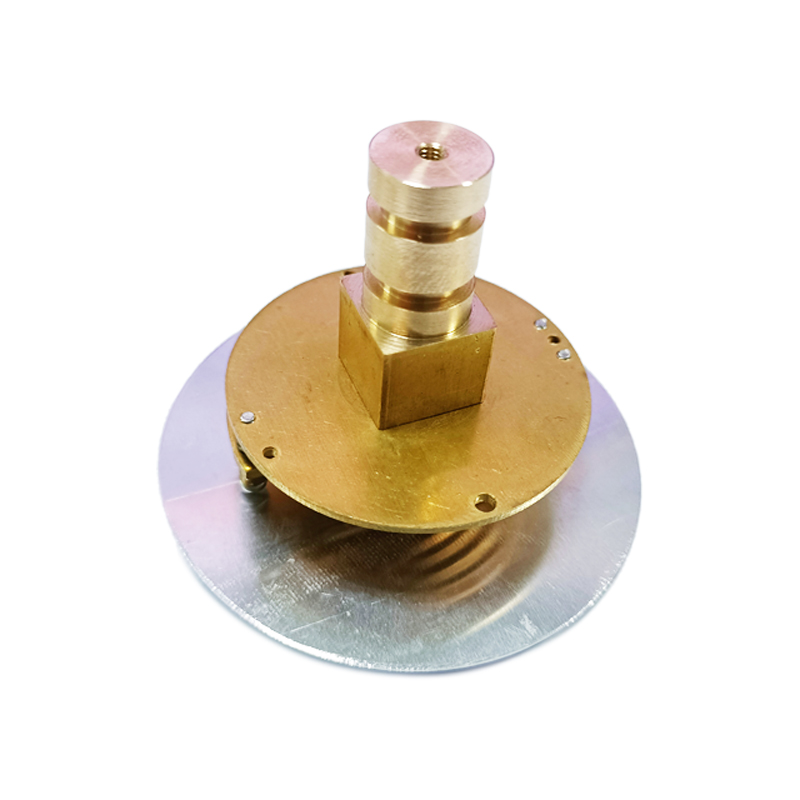

A diaphragm pressure gauge consists of a diaphragm, typically made of materials like stainless steel or brass, that deflects under pressure. This deflection is translated into a readable output, usually in the form of a dial or a digital reading. When pressure is applied to one side of the diaphragm, it bends or flexes. This movement is then transmitted through a mechanical linkage or electronic sensor to indicate pressure on the gauge's display.

Working Principle

The operation of a diaphragm pressure gauge is based on the principle of differential pressure measurement. In a simple setup, one side of the diaphragm is exposed to the pressure of the fluid (gas or liquid) being measured, while the other side is usually at atmospheric pressure or vacuum. As pressure changes, the diaphragm's deflection changes proportionally, which in turn alters the position of the needle on the gauge or the reading on a digital display.

Types of Diaphragm Pressure Gauges

There are various types of diaphragm pressure gauges, each designed for specific applications

1. Bourdon Tube Gauges These use a Bourdon tube in conjunction with a diaphragm for enhanced accuracy and sensitivity. They are often used in environments where precise measurements are critical. 2. Differential Pressure Gauges These measure the difference between two pressures and are invaluable in applications such as filtration and pump systems.

3. Absolute Pressure Gauges These gauges measure pressure relative to a perfect vacuum, making them useful for processes requiring precise absolute pressure readings.

4. Digital Pressure Gauges Utilizing electronic sensors, digital gauges provide a clear, easily readable output and are less susceptible to mechanical wear and tear.

Advantages of Diaphragm Pressure Gauges

Diaphragm pressure gauges offer several advantages that contribute to their widespread use

wholesale explain diaphragm pressure gauge

- Accuracy Diaphragm gauges provide high accuracy, essential for critical process control

.- Durability Built with robust materials, they can withstand harsh environmental conditions, chemical exposure, and high pressures.

- Versatility Suitable for a wide range of applications, including oil and gas, food processing, pharmaceuticals, and HVAC systems.

- Ease of Maintenance Diaphragm pressure gauges have fewer moving parts, reducing the potential for mechanical failure and minimizing maintenance requirements.

Wholesale Considerations

When considering diaphragm pressure gauges for wholesale purchasing, it's essential to evaluate several key factors

1. Quality Assurance Ensure that the gauges meet industry standards and regulations. Certifications such as ISO and ASME can indicate reliability.

2. Supplier Reputation Choose suppliers with a proven track record in providing high-quality pressure measurement devices. Customer reviews and testimonials can offer insight into a supplier's reliability.

3. Cost-Effectiveness While wholesale purchasing generally provides cost advantages, it's crucial to balance cost with quality. Opt for gauges that deliver both reliability and affordability to maximize your investment.

4. Customization Options Some applications may require specific features or configurations. Verify that your supplier can provide custom gauges tailored to your needs.

5. After-Sales Support A supplier that offers strong customer support, warranties, and technical assistance can save you time and trouble in the long run.

Conclusion

Diaphragm pressure gauges play a critical role in ensuring the accurate measurement of pressure across various industries. Their robust design, high accuracy, and versatility make them indispensable tools for engineers and technicians alike. When looking to purchase diaphragm pressure gauges wholesale, it’s essential to consider factors such as quality, supplier reputation, cost, customization, and after-sales support. By focusing on these aspects, businesses can ensure they acquire reliable instruments that meet their specific pressure measurement needs.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025