Nov . 05, 2024 00:05 Back to list

wholesale diaphragm vacuum pressure gauge

Understanding Wholesale Diaphragm Vacuum Pressure Gauges

In industrial and commercial settings, accurate measurement of pressure is crucial for maintaining operational efficiency and ensuring safety. Among the various types of pressure measuring devices, diaphragm vacuum pressure gauges stand out due to their reliability and precision. This article will explore the significance of wholesale diaphragm vacuum pressure gauges, their working principles, applications, and advantages in various sectors.

What is a Diaphragm Vacuum Pressure Gauge?

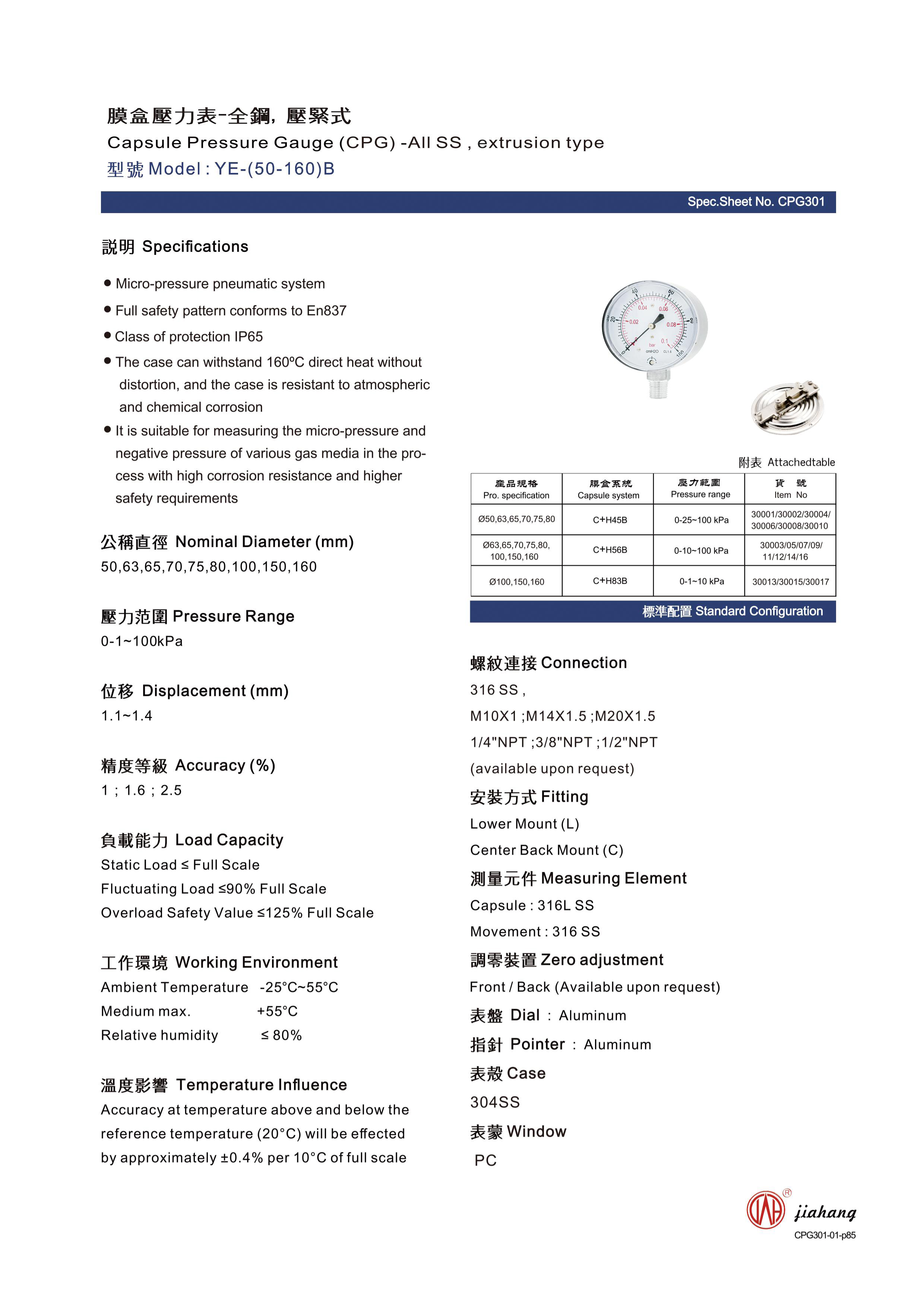

A diaphragm vacuum pressure gauge is a type of sensor used to measure low-pressure conditions in a vacuum system. It typically consists of a flexible diaphragm that responds to pressure changes. When the pressure in the system changes, the diaphragm deflects. This movement is then translated into a readable measurement, providing operators with essential data required for effective monitoring and control.

Working Principle

The working principle of a diaphragm vacuum pressure gauge is straightforward. The diaphragm is usually made from a material that can flex easily under pressure changes. The pressure inside the vacuum system acts on one side of the diaphragm, while the other side is exposed to ambient atmospheric pressure. As the internal pressure varies, the diaphragm bends in response. This movement is mechanically linked to a pointer or a digital readout, displaying the current pressure level.

Some gauges are also equipped with electronic sensors that can provide even greater accuracy and can be connected to data logging systems for real-time monitoring.

Applications

Diaphragm vacuum pressure gauges find extensive applications in various fields, including

1. Laboratories Used for controlling and monitoring low-pressure environments during experiments and research, ensuring that conditions are optimal for sensitive processes.

2. Manufacturing In processes such as vacuum forming and packaging, these gauges help maintain the required pressure levels to ensure product quality and safety.

wholesale diaphragm vacuum pressure gauge

3. HVAC Systems Used in heating, ventilation, and air conditioning systems to monitor pressure levels, contributing to energy efficiency and system reliability.

5. Food Processing Applied in processes to guarantee that products are sealed properly and safe for consumption by monitoring vacuum levels during packaging.

Advantages of Diaphragm Vacuum Pressure Gauges

1. Precision and Reliability Diaphragm gauges provide highly accurate readings, which are essential for applications where pressure fluctuation can lead to significant issues.

2. Durability Constructed from robust materials, these gauges can withstand harsh environments, ensuring longevity and reduced maintenance costs.

3. Ease of Installation Diaphragm gauges are straightforward to install and require minimal calibration, making them user-friendly for operators.

4. Cost-Effectiveness When purchased wholesale, diaphragm vacuum pressure gauges can be acquired at lower prices, making them a financially sound choice for companies looking to equip multiple systems.

5. Wide Range of Measurement These gauges can measure a range of pressures, making them versatile enough for different applications across various industries.

Conclusion

In summary, wholesale diaphragm vacuum pressure gauges play an essential role in modern industry, enabling precise pressure measurement for a multitude of applications. Their reliability and accuracy make them an indispensable tool in maintaining optimal conditions in various processes. When businesses invest in these devices, particularly in bulk, they ensure both quality and cost efficiency, ultimately contributing to operational success. As the demand for accuracy and efficiency continues to rise, diaphragm vacuum pressure gauges will remain a critical component in the quest for higher standards in industrial and commercial applications.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025