Nov . 22, 2024 16:22 Back to list

wholesale calibrating differential pressure gauge

Understanding Wholesale Calibrating Differential Pressure Gauges

In various industrial applications, accurate pressure measurement is vital for ensuring optimal performance and safety. Differential pressure gauges are essential tools utilized in a range of settings, from HVAC systems and water treatment facilities to oil and gas applications. This article will delve into the importance of wholesale calibrating differential pressure gauges, their working principles, applications, and the benefits they offer.

What is a Differential Pressure Gauge?

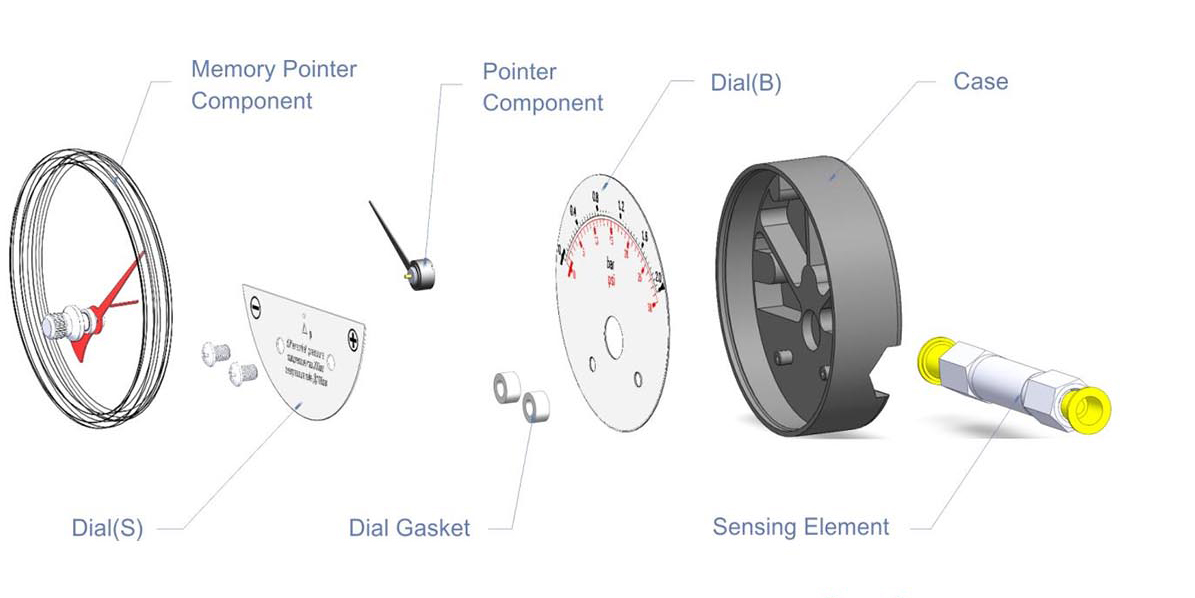

A differential pressure gauge measures the difference in pressure between two points. This type of gauge is crucial for monitoring processes where pressure drop can indicate issues such as blockages, leaks, or equipment malfunction. These gauges consist of two pressure sensing ports, which allow them to measure pressure differentials across filters, pipes, or any equipment.

The Importance of Calibration

Calibration is the process of configuring an instrument to provide a result for a sample within an acceptable range. The accuracy of a differential pressure gauge is paramount as even small inaccuracies can lead to significant operational problems. Therefore, wholesale calibration of these gauges ensures they deliver precise measurements.

When differential pressure gauges are calibrated, they are tested against a standard under controlled conditions. This process identifies any discrepancies and allows technicians to adjust the gauge accordingly. Regular calibration of these instruments is not just best practice; it is often a regulatory requirement in industries that demand high levels of safety and compliance.

Wholesale Calibration Services

Wholesale calibration refers to the process of calibrating multiple instruments or devices at once, typically offered by specialized service providers. For businesses that utilize several differential pressure gauges, wholesale calibration can be an efficient and cost-effective solution. It allows for bulk services at reduced rates and can minimize downtime, leading to greater operational efficiency.

Many calibration service providers offer comprehensive packages that include testing, adjustments, and certification

. The certifications can be crucial for industries where proving compliance with standards (such as ISO or ASME) is mandatory. A certified gauge ensures that manufacturers and service providers can trust their measurements, leading to safer and more efficient operations.wholesale calibrating differential pressure gauge

Applications of Differential Pressure Gauges

Differential pressure gauges are extensively used across various industries. In HVAC systems, they monitor the pressure difference between the air supply and return, helping ensure proper ventilation and system efficiency. In water treatment facilities, these gauges help track the pressure drop across filters, preventing clogs that can disrupt operations. In the oil and gas sector, they are critical for measuring pressure differences in pipelines, which aids in leak detection and system monitoring.

In addition to these applications, differential pressure gauges also play essential roles in pharmaceutical manufacturing, food processing, and chemical production. In each application, maintaining the accuracy and reliability of measurements can lead to product quality, operational efficiency, and compliance with industry regulations.

Benefits of Quality Differential Pressure Gauges

The benefits of using high-quality, accurately calibrated differential pressure gauges are numerous. Firstly, they provide reliable data that can inform decision-making and troubleshooting. Accurate pressure readings can help industries avoid expensive equipment failures and ensure safety in operations.

Additionally, well-calibrated gauges contribute to energy efficiency in HVAC systems and other applications. By monitoring pressure differences effectively, businesses can optimize their processes, reduce energy consumption, and lower operational costs.

Lastly, using calibrated differential pressure gauges fosters regulatory compliance. Many industries face strict regulations regarding equipment performance, and failure to comply can lead to penalties. Regular calibration ensures that businesses can pass inspections and maintain their licenses to operate.

Conclusion

In conclusion, wholesale calibrating differential pressure gauges plays a crucial role in various industries. These instruments are vital for ensuring accurate pressure measurements, which directly affect operational efficiency and safety. By investing in quality differential pressure gauges and utilizing wholesale calibration services, businesses can ensure they operate smoothly while meeting regulatory requirements. As industries continue to evolve, the importance of precise measurements will remain a cornerstone of effective management and operations.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025