Aug . 31, 2024 20:05 Back to list

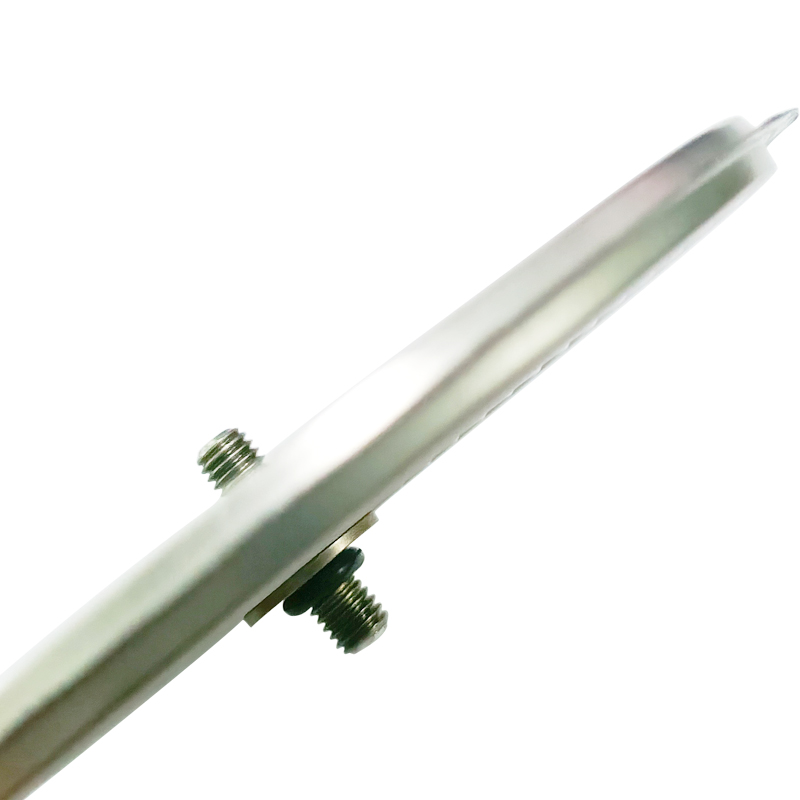

wholesale low pressure differential pressure gauge

Understanding Wholesale Low Pressure Differential Pressure Gauges

In industrial and commercial settings, the measurement of pressure is crucial for ensuring the safe and efficient operation of systems and processes. One specific type of gauge that plays a vital role in these environments is the low pressure differential pressure gauge. Understanding its functionality, importance, and applications can significantly benefit businesses looking to optimize their operations and ensure safety standards.

What is a Low Pressure Differential Pressure Gauge?

A low pressure differential pressure gauge is a device used to measure the difference in pressure between two points in a system. Unlike standard pressure gauges that measure absolute or gauge pressure, differential pressure gauges focus on the pressure difference, which can be critical for various applications, including HVAC systems, filtration processes, and fluid transport.

These gauges typically feature a sensor that detects pressure from two sources, calculating the difference and displaying it on a readable dial or digital screen. They are designed to operate accurately at low pressure ranges, which is essential for many sensitive applications where even slight variations can impact performance.

Importance of Differential Pressure Measurement

The accurate measurement of differential pressure is vital for several reasons

1. System Performance In processes like air filtration and HVAC, monitoring differential pressure helps determine when filters are clogged or when there are blockages in ducts. By ensuring optimal airflow, businesses can maintain efficiency and reduce energy consumption.

wholesale low pressure differential pressure gauge

2. Safety In many industries, maintaining pressure differentials is crucial for safety. For instance, in cleanroom environments or chemical processing facilities, an improper pressure differential could lead to contamination or unsafe working conditions.

3. Preventive Maintenance Regular monitoring of differential pressures allows for timely maintenance and servicing of equipment. By analyzing pressure trends, companies can predict when a component may fail, thereby preventing costly downtimes.

Applications in Various Industries

Low pressure differential pressure gauges are used across a wide range of industries. In the HVAC industry, they monitor air pressure across filters and coils to ensure optimal operation. In the pharmaceutical and food industries, they are used to maintain clean environments by ensuring that air pressure differentials are kept within specified ranges.

Additionally, in water treatment plants, these gauges monitor pressure across membranes in filtration systems, ensuring efficient operation and compliance with safety regulations. The versatility of these gauges makes them indispensable tools in modern industrial applications.

Conclusion

In conclusion, wholesale low pressure differential pressure gauges are essential instruments for many industries. Their role in measuring and managing pressure differences ensures optimal performance, enhances safety, and supports preventive maintenance practices. As industries continue to evolve, the reliance on precision instruments like differential pressure gauges will only increase, making them a critical component in various operational strategies. By investing in quality gauges and implementing regular monitoring practices, businesses can significantly enhance their efficiency, safety, and overall productivity.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025