Aug . 30, 2024 20:43 Back to list

wholesale diaphragm and capsule pressure gauges

Understanding Wholesale Diaphragm and Capsule Pressure Gauges

Diaphragm and capsule pressure gauges play a crucial role in various industrial applications, providing reliable and accurate pressure measurements. These instruments are essential in processes where monitoring pressure is vital for safety, efficiency, and operational integrity. For industries involved in manufacturing, oil and gas, pharmaceuticals, and food production, understanding the wholesale supply and functionality of these gauges is paramount.

Diaphragm Pressure Gauges

Diaphragm pressure gauges utilize a flexible membrane, or diaphragm, to measure pressure changes. When pressure is applied to one side of the diaphragm, it deflects, creating a mechanical movement that can be translated into a pressure reading. These gauges are particularly effective for measuring gas and liquid pressures in harsh environments, as they can withstand corrosive media and high temperatures.

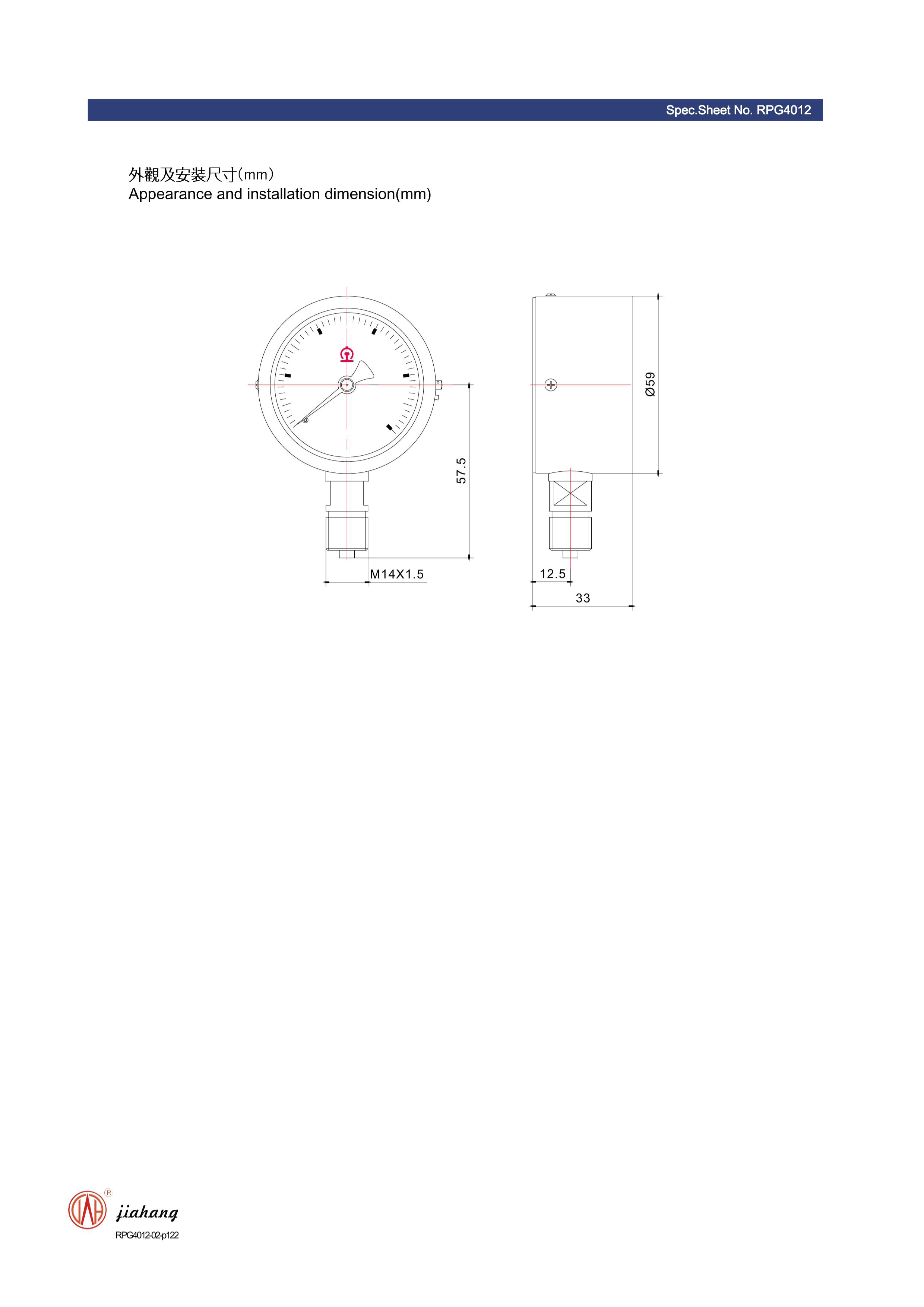

Wholesale diaphragm pressure gauges are available in various designs, materials, and specifications. Common materials include stainless steel, brass, and plastic, which are chosen based on the application requirements, such as chemical compatibility and temperature resistance. Additionally, manufacturers offer a range of sizes to accommodate different installation needs, ensuring that users can find the right gauge for their specific applications.

Capsule Pressure Gauges

wholesale diaphragm and capsule pressure gauges

Capsule pressure gauges function similarly but utilize a different mechanism. They incorporate a capsule element usually made of two metallic capsules sealed together. As pressure is applied, the capsules expand and contract, providing a pressure reading through a pointer mechanism. Capsule gauges are particularly valuable for measuring low pressure, making them ideal for applications like HVAC systems and gas distribution.

When looking for wholesale capsule pressure gauges, it is crucial to consider accuracy, durability, and the specific pressure range required for the application

. These gauges are often favored in applications where precise low-pressure measurements are necessary, as they can detect minute changes in pressure that might be critical in maintaining system performance.Market Trends and Considerations

The demand for diaphragm and capsule pressure gauges has seen a steady increase, driven by advancements in technology and the need for more accurate and reliable measurement solutions. Industries are focusing on integrating smart technologies, such as IoT capabilities, which allow for real-time monitoring and data analysis.

When purchasing wholesale diaphragm and capsule pressure gauges, it's essential to assess suppliers' quality certifications and customer service offerings. Reliable suppliers should provide a warranty, technical support, and comprehensive documentation to assist users in installation and maintenance.

In conclusion, diaphragm and capsule pressure gauges are indispensable tools across various sectors. Understanding their functionality, strengths, and market availability is crucial for industries that rely on accurate pressure measurements. By selecting the right wholesale supplier, businesses can ensure they have the correct instrumentation to enhance their operational efficiency and safety.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025