Sep . 10, 2024 00:07 Back to list

vacuum differential pressure gauge products

Understanding Vacuum Differential Pressure Gauge Products

In various industrial applications, accurate measurement of pressure is essential for ensuring optimal performance and safety. One of the crucial instruments used in this context is the vacuum differential pressure gauge. This device is specifically designed to measure the difference between two pressures, one of which is often below atmospheric pressure. Understanding its functionalities, applications, and advantages can help industries choose the right gauge for their needs.

What is a Vacuum Differential Pressure Gauge?

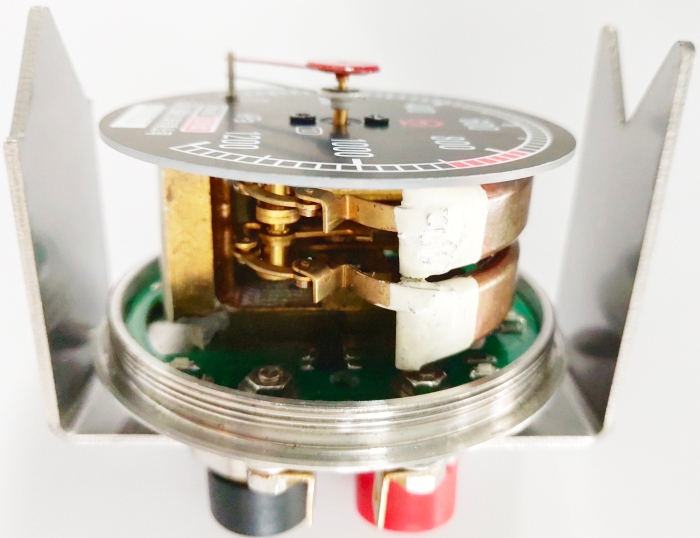

A vacuum differential pressure gauge measures the pressure difference between a reference point and a measurement point within a system that operates under vacuum conditions. It essentially captures minute changes in pressure, which is critical in processes where precise control of gas or fluid movement is necessary.

Typically, these gauges feature a diaphragm or a spring-loaded mechanism that moves in response to pressure changes. The movement translates into a reading on a dial or a digital display, allowing operators to monitor system conditions in real-time.

Applications

Vacuum differential pressure gauges find applications across multiple sectors, including

1. Manufacturing In processes that require precise control over gas flow or entry into vacuum chambers, these gauges help maintain the desired vacuum levels. This accuracy is vital for ensuring quality in products like semiconductors or pharmaceuticals.

2. Food and Beverage Industry Monitoring differential pressure is essential during packaging processes that involve vacuum sealing. Maintaining an optimal vacuum ensures product freshness and shelf life.

vacuum differential pressure gauge products

3. HVAC Systems In heating, ventilation, and air conditioning systems, vacuum differential pressure gauges help in monitoring air flow and ensuring that systems are functioning correctly, leading to energy efficiency and comfort.

4. Research and Development In laboratory settings, understanding pressure differentials is crucial for experiments involving reactions under vacuum or in controlled environments.

Advantages of Vacuum Differential Pressure Gauges

1. Precision These gauges provide highly accurate readings, which are vital for maintaining the integrity of various processes. High precision minimizes the risk of product failure or operational hazards.

2. Durability Most vacuum differential pressure gauges are designed to withstand harsh environments, making them suitable for various industrial settings. They are built to resist corrosion, vibration, and temperature fluctuations.

3. Versatility Given their range of applications, these gauges can be utilized in different industries, making them a flexible tool for engineers and operators.

4. Easy Integration Many models offer modular designs that facilitate easy installation and integration into existing systems, ensuring minimal disruption during implementation.

Conclusion

Vacuum differential pressure gauge products are instrumental across many industries where precise pressure measurement is vital. Their ability to provide accurate and timely data not only enhances operational efficiency but also contributes to safety and quality assurance. Whether in manufacturing, food processing, HVAC systems, or research laboratories, these gauges are an essential part of modern industrial equipment. As technology continues to advance, the development of more sophisticated gauge products promises even greater accuracy and efficiency, paving the way for innovations in various fields. Investing in high-quality vacuum differential pressure gauges is an investment in operational excellence and safety.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025