Dec . 04, 2024 09:19 Back to list

types of differential pressure gauges jah

Types of Differential Pressure Gauges Understanding the Basics

Differential pressure gauges are essential instruments used in various industries to measure the difference in pressure between two points in a system. This measurement is crucial in processes such as fluid flow, filtration, and HVAC systems. Understanding the different types of differential pressure gauges can help professionals select the right device for their specific applications. In this article, we will explore the primary types of differential pressure gauges, their principles of operation, and their applications.

1. Mechanical Differential Pressure Gauges

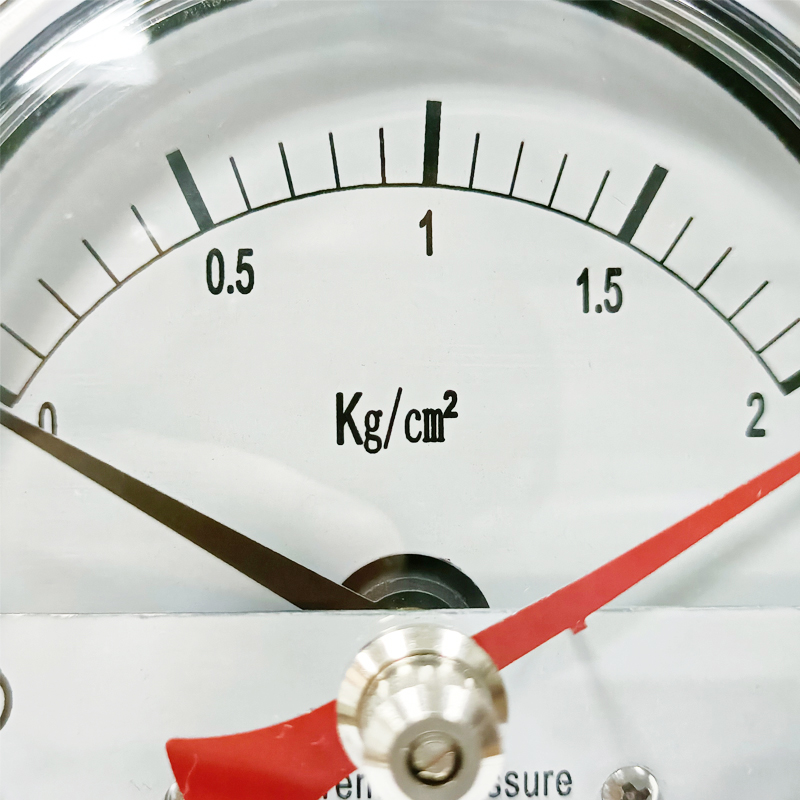

Mechanical differential pressure gauges are among the oldest and most widely used types of gauges. They typically employ a Bourdon tube or diaphragm to measure pressure differences. The Bourdon tube is a curved, metallic tube that straightens when pressure is applied, causing a pointer to move along a calibrated scale. In a diaphragm gauge, two flexible diaphragms separate the two pressure points. As pressure differences cause the diaphragms to flex, the movement turns a mechanical indicator.

Applications These gauges are commonly used in industrial processes, HVAC systems, and other applications where straightforward, reliable pressure measurements are needed. Their robustness and simplicity make them suitable for harsh environments.

2. Electronic Differential Pressure Gauges

Electronic differential pressure gauges utilize electronic sensors to measure pressure differences. These devices often employ piezoresistive or capacitive pressure sensors that convert the pressure difference into an electrical signal. This signal is then processed and displayed using digital readouts or transmitted to a control system.

Applications Electronic gauges are favored in applications requiring high precision and advanced features such as data logging, remote monitoring, or integration into automation systems. They are commonly used in laboratories, clean rooms, and advanced manufacturing processes.

3. Capacitive Differential Pressure Gauges

Capacitive differential pressure gauges operate based on changes in capacitance between two conductive plates caused by pressure differences. As the pressure varies, the distance between the plates changes, altering the capacitance, which is then converted into a pressure reading.

Applications These gauges are excellent for applications that demand high accuracy and stability, making them ideal for use in pharmaceuticals, food processing, and other sensitive environments.

types of differential pressure gauges jah

4. Piezoresistive Differential Pressure Sensors

Piezoresistive sensors are a type of electronic gauge that utilizes the piezoresistive effect, where the electrical resistance of a material changes with applied pressure. These sensors measure the pressure difference by detecting variations in resistance and converting them into an electrical signal.

Applications Due to their high sensitivity and compact size, piezoresistive sensors are used in numerous applications, including medical devices, automotive systems, and process control.

5. Tunable Diode Laser Absorption Spectroscopy (TDLAS) Differential Pressure Gauges

Though relatively new, tunable diode laser absorption spectroscopy gauges offer a unique method for measuring differential pressure. They utilize laser technology to detect changes in the absorption characteristics of gases, allowing for non-contact, highly accurate pressure measurements.

Applications TDLAS gauges are particularly useful in environmental monitoring, emissions testing, and other applications where precise gas concentration measurement is required.

6. Barometric Differential Pressure Gauges

Barometric differential pressure gauges utilize a barometric measurement to determine differential pressure. These gauges measure the difference between atmospheric pressure and the pressure within a system, providing critical data for applications where ambient pressure fluctuations are a concern.

Applications Common applications include HVAC systems, where maintaining indoor air quality is crucial, and processes sensitive to atmospheric pressure changes.

Conclusion

Differential pressure gauges play a vital role in various industries by providing accurate pressure measurements essential for monitoring and controlling processes. From mechanical devices that have stood the test of time to advanced electronic sensors, each type of differential pressure gauge serves specific needs and applications. Understanding the differences among these gauges allows technicians and engineers to choose the right instrument for their operations, enhancing efficiency, safety, and performance within their systems. As technology continues to evolve, the development of new and improved differential pressure measurement techniques will likely contribute to even greater advancements across various fields.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025