Dec . 10, 2024 20:28 Back to list

Different Categories of Differential Pressure Gauges for Industrial Applications

Understanding Different Types of Differential Pressure Gauges

Differential pressure gauges are essential instruments widely used in various industries to measure the pressure difference between two points in a system. This measurement is crucial for monitoring processes, maintaining safety, and ensuring efficient operations in applications ranging from HVAC systems to chemical processing. This article provides an overview of the primary types of differential pressure gauges, discussing their functionality, applications, and advantages.

1. Bourdon Tube Differential Pressure Gauges

One of the most common types of differential pressure gauges is the Bourdon tube gauge. This gauge uses a coiled, flexible tube that responds to changes in pressure. When pressure is applied, the tube tends to straighten out, and this movement is translated into a dial reading. Bourdon tube gauges are known for their durability and reliability. They are suitable for measuring moderate pressures and are often used in industrial applications, including oil and gas, water treatment, and manufacturing processes.

2. Diaphragm Differential Pressure Gauges

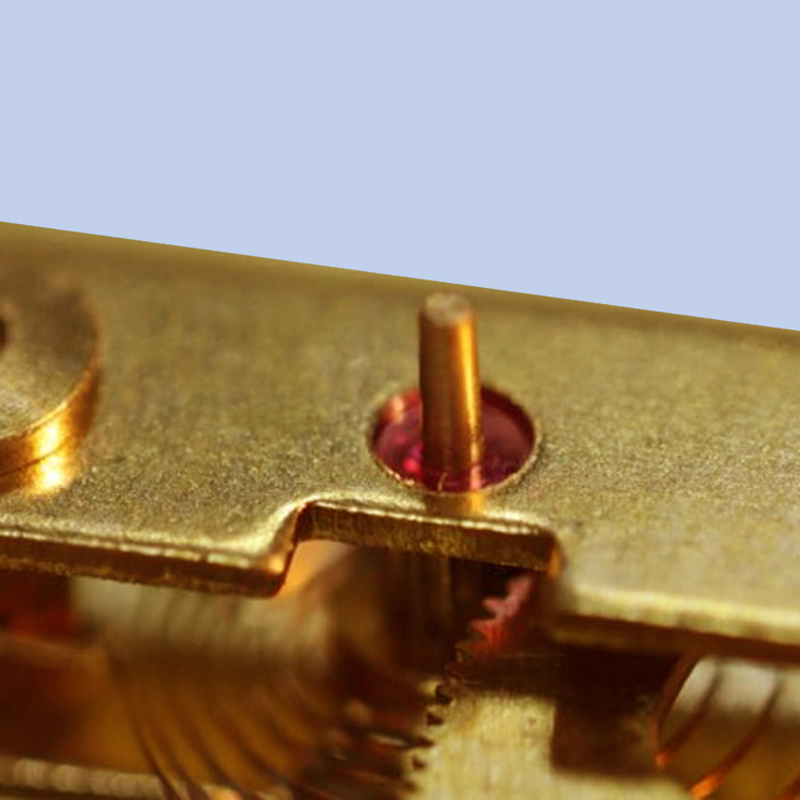

Diaphragm gauge operates using a flexible membrane or diaphragm that separates two pressure chambers. When there is a pressure difference, the diaphragm deflects, and this movement is translated into a reading. Diaphragm gauges are particularly useful for measuring low differential pressures and are less affected by external vibrations, making them ideal for sensitive applications. These gauges are frequently used in pharmaceutical, food processing, and laboratory environments where accuracy and hygiene are paramount.

3. Capacitive Differential Pressure Gauges

Capacitive differential pressure gauges utilize conductive plates to measure pressure differences. When pressure is applied, the distance between the plates changes, which in turn alters the capacitance. This variation is then converted into a digital reading. Capacitive gauges are known for their high precision and reliability, especially in applications involving clean rooms and semiconductor manufacturing, where even slight pressure variations can lead to significant complications.

types of differential pressure gauges company

4. Orifice Plate Differential Pressure Gauges

Orifice plate gauges measure differential pressure by observing the pressure drop across an orifice plate inserted in a pipeline. As fluid flows through the orifice, the pressure on the upstream side decreases, and this difference can be measured. Orifice plate gauges are extensively used in flow measurement and process control, particularly in industries involving fluids and gas, such as oil and gas exploration. They excel in applications with large flow rates and are relatively easy to install and maintain.

5. Strain Gauge Differential Pressure Transmitters

Strain gauge differential pressure transmitters are electronic devices that use strain gauges to convert pressure changes into an electrical signal. These transmitters offer high accuracy and can transmit data over long distances, making them suitable for modern automated systems and remote monitoring applications. Their versatility allows for use in many industries, including aerospace, automotive, and environmental monitoring.

6. Digital Differential Pressure Gauges

Digital gauges offer a modern alternative to traditional mechanical gauges. They combine advanced technology with user-friendly interfaces, often featuring LCD displays that provide real-time readings, data logging capabilities, and alarm functions. Digital differential pressure gauges are widely used in HVAC systems, cleanrooms, and laboratory settings, where clarity of data and ease of use are paramount.

Conclusion

In conclusion, differential pressure gauges play a critical role in various industries by providing essential measurements that ensure safety and efficiency. From Bourdon tube gauges, which are favored for their robustness, to digital gauges that offer advanced functionality, the choice of differential pressure gauge depends on specific application requirements, including the environment, pressure range, and the exact nature of the fluids being measured. Understanding the different types allows industries to select the most appropriate gauge, optimizing their processes and enhancing operational safety. As technology continues to evolve, we can expect further innovations in the design and functionality of these vital instruments.

-

High-Quality Pressure Gauge on Fire Extinguisher - Reliable Water Fire Extinguisher Pressure Gauge Suppliers & Exporters

NewsJul.08,2025

-

High-Quality Water Pressure Differential and Gauge Kit Reliable Manufacturers & Competitive Quotes

NewsJul.08,2025

-

High-Precision Digital Diaphragm Pressure Gauge – Reliable Manufacturer & Competitive Quotes

NewsJul.07,2025

-

Wholesale Diaphragm Pressure Gauge Supplier - Premium Quality & Competitive Price

NewsJul.07,2025

-

Digital Diaphragm Pressure Gauge Reliable & Precise Measurement Top Manufacturers Quotes

NewsJul.06,2025

-

High Accuracy Piston Type Differential Pressure Gauge - Reliable Manufacturers & Competitive Quotes

NewsJul.06,2025