Aug . 14, 2024 04:56 Back to list

Top Companies for Isolating Diaphragm Pressure Gauges and Their Innovative Solutions

Understanding the Role of Isolating Diaphragm Pressure Gauges in Industrial Applications

In the realm of industrial measurement and control, the importance of accurate pressure readings cannot be overstated. Pressure gauges play a crucial role in monitoring the performance and safety of various systems across multiple sectors. Among the different types of pressure gauges, the isolating diaphragm pressure gauge stands out for its unique construction and functionality. This article explores the significance of isolating diaphragm pressure gauges, their working principles, and the leading companies that specialize in their manufacturing.

What is an Isolating Diaphragm Pressure Gauge?

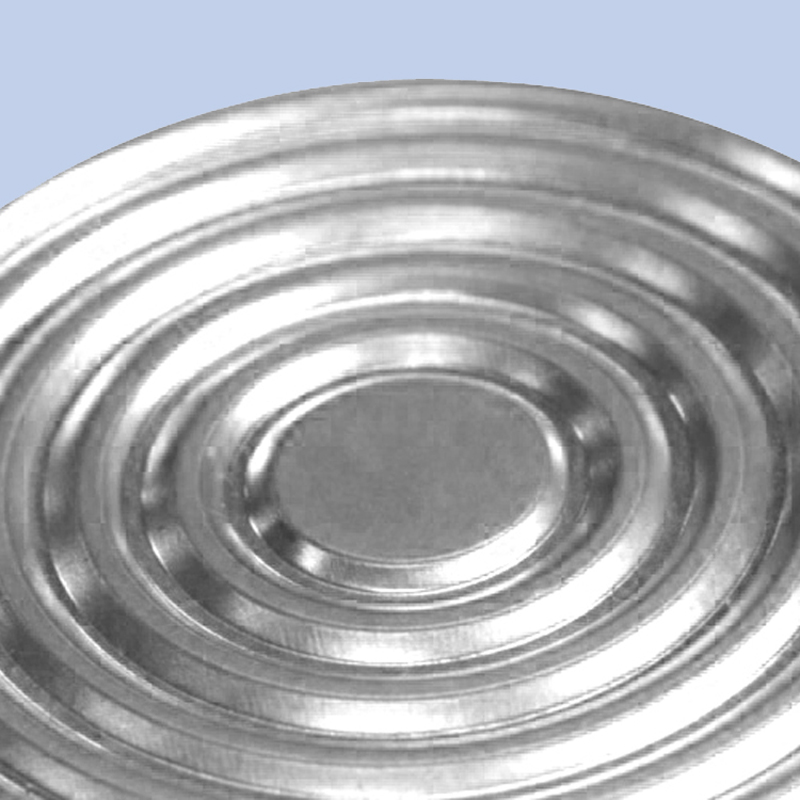

An isolating diaphragm pressure gauge is a specialized instrument designed to measure the pressure of gases or liquids while providing a barrier between the fluid and the measuring element. This is achieved through a flexible diaphragm that separates the process fluid from the pressure sensing element, typically a bourdon tube or a piezoresistive sensor. The diaphragm isolates the measuring mechanism from potential corrosion, contamination, and clogging, making these gauges ideal for harsh and viscous fluids.

Working Principles

The operational principle of an isolating diaphragm pressure gauge is relatively straightforward. When pressure is applied to the diaphragm, it deforms, transferring the force to the sensing element. The amount of deformation is proportional to the pressure of the fluid being measured. This information is then translated into a readable value on the gauge's dial or digital display.

The diaphragm material is carefully selected based on the specific application, including considerations for chemical compatibility, temperature resistance, and pressure range. Common materials include stainless steel, Teflon, and various elastomers.

Applications

Isolating diaphragm pressure gauges are widely used in various industries, including

- Oil and Gas They are essential for monitoring pressure in pipelines and storage tanks where corrosive substances are present. - Food and Beverage Given the stringent hygiene standards, these gauges ensure accurate pressure readings without contamination. - Pharmaceuticals In processes where precision is critical, isolating diaphragm gauges help maintain product integrity. - Water Treatment They monitor pressure in systems dealing with wastewater and other fluids that may cause traditional gauges to fail. - Chemical Processing These gauges withstand aggressive chemicals, ensuring reliable readings and improving safety.

isolating diaphragm pressure gauge companies

Leading Companies in the Market

Several companies are well-regarded in the production of isolating diaphragm pressure gauges, offering innovative solutions to meet diverse industrial needs. Here are a few notable players

1. WIKA Instrument, LP As one of the leading manufacturers in pressure measurement technology, WIKA offers a comprehensive range of isolating diaphragm gauges known for their reliability and accuracy.

2. Emerson (Rosemount) Emerson's Rosemount brand is synonymous with advanced measuring instruments. Their isolating diaphragm gauges excel in providing precise pressure readings even in the most challenging environments.

3. Honeywell Renowned for its innovative technologies, Honeywell provides robust isolating diaphragm pressure gauges that cater to various industries, ensuring operational safety and efficiency.

4. Ashcroft Inc. With a long history in pressure instrumentation, Ashcroft offers a wide selection of isolating diaphragm gauges, designed for durability and high performance across different applications.

5. Kobold Instruments Specializing in fluid measurement, Kobold provides customizable isolating diaphragm gauges that meet specific industry requirements.

Conclusion

Isolating diaphragm pressure gauges exemplify the fusion of innovation and reliability in industrial measurement technology. Their ability to provide accurate pressure readings while protecting against harsh environmental factors makes them indispensable in many sectors. As industries continue to evolve, the demand for reliable measurement solutions will only increase, paving the way for continued advancements in isolating diaphragm pressure gauge technology by esteemed companies in the field.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025