Sep . 23, 2024 23:08 Back to list

Diaphragm Pressure Gauge for Accurate Measurement and Reliable Performance in Various Applications

Understanding Diaphragm Pressure Gauges A Comprehensive Overview

Diaphragm pressure gauges are essential instruments in various industrial applications, measuring the pressure of gases and liquids. Their design is built on a simple yet effective principle that allows for an accurate and reliable assessment of pressure within closed systems. This article aims to explore the functionality, advantages, and applications of diaphragm pressure gauges.

Understanding Diaphragm Pressure Gauges A Comprehensive Overview

One of the primary advantages of diaphragm pressure gauges is their ability to accurately measure low pressures. They excel in applications where precise pressure readings are critical, such as in laboratories, chemical processing, and food production. Additionally, diaphragm pressure gauges can handle corrosive and viscous fluids, especially when equipped with appropriate materials and coatings. This adaptability makes them suitable for hostile environments, including those found in oil and gas extraction or wastewater treatment facilities.

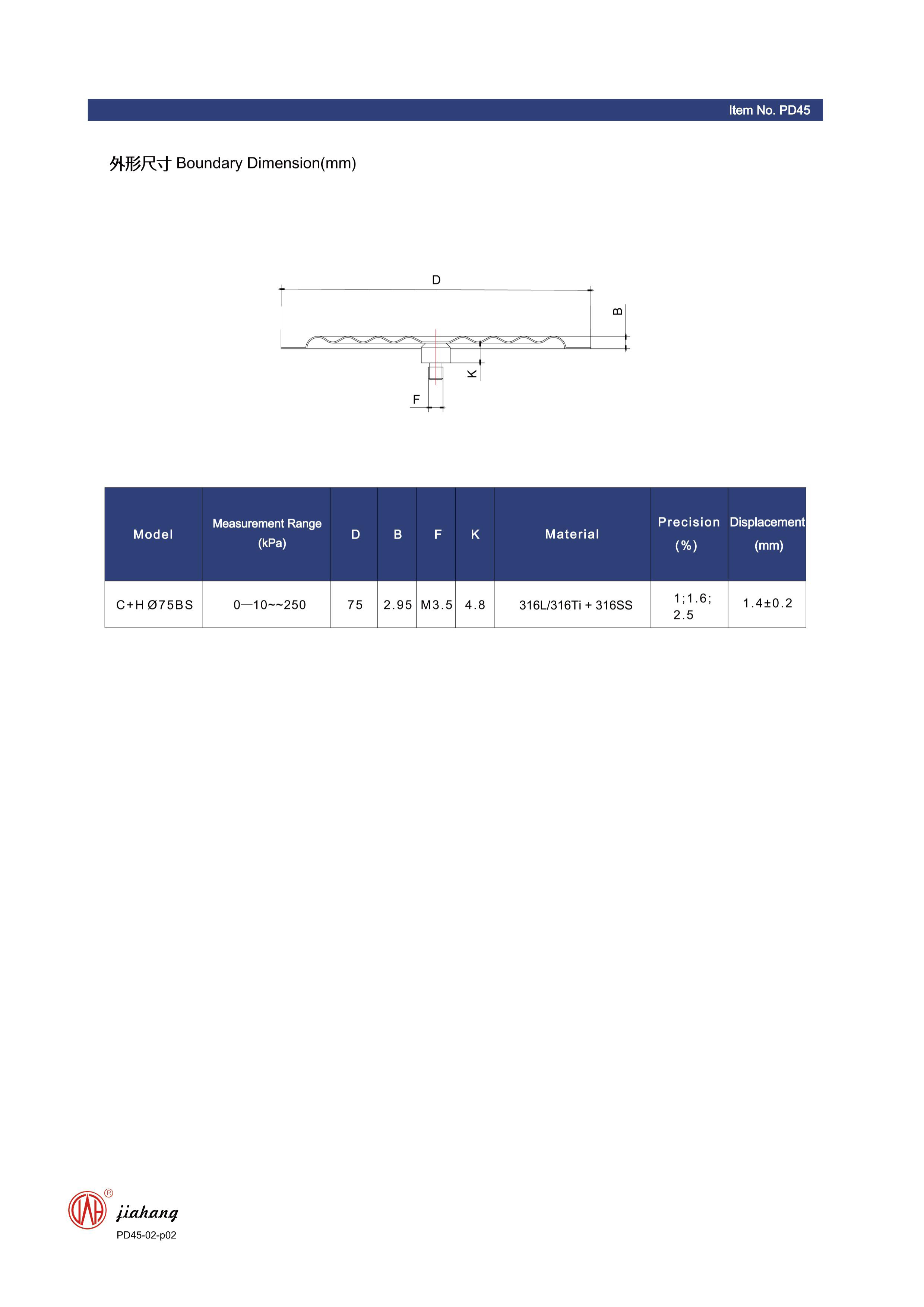

the diaphragm pressure gauge product

Another key benefit is their robust construction. Diaphragm pressure gauges are designed to withstand high shock loads and vibrations, which can often hinder other types of pressure gauges. This durability translates into a longer lifespan and lower maintenance requirements, reducing downtime and overall operational costs. Moreover, many models offer both analog and digital displays, allowing users to select their preferred method of reading pressure levels.

Diaphragm pressure gauges also come equipped with a variety of options to suit specific applications. For instance, many gauges are available in different materials, such as stainless steel or plastic, providing resistance to various chemicals and environmental conditions. Furthermore, features such as over-pressure protection, which safeguards the diaphragm against excessive pressure, enhance their reliability even in demanding conditions.

In terms of applications, diaphragm pressure gauges find use across various industries, including pharmaceuticals, food and beverage, water treatment, and HVAC systems. They are essential for monitoring processes, ensuring safety, and maintaining efficiency in operations. For instance, in the food and beverage industry, these gauges can help maintain specific pressures necessary for the proper carbonation of beverages or the operation of sterile processes.

In conclusion, diaphragm pressure gauges are indispensable tools in contemporary industries, providing accurate, reliable, and versatile pressure measurements. Their unique design and numerous benefits make them ideal for a wide range of applications where precision and durability are essential. As technology advances, the role of diaphragm pressure gauges is likely to expand, continuing to meet the growing demands of various sectors. Understanding their functionality and applications will enable industries to harness their full potential, ensuring optimal performance and safety in their operations.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025