Oct . 18, 2024 20:36 Back to list

Swagelok Differential Pressure Gauge Pricing and Options Overview

Understanding Swagelok Differential Pressure Gauge Pricing

In the realm of industrial applications, the measurement of differential pressure is crucial for ensuring process efficiency, safety, and reliability. Swagelok, a renowned manufacturer of fluid system components, offers an extensive range of differential pressure gauges that cater to various industrial needs. Understanding the pricing structure and factors that influence these prices is essential for businesses and engineers who rely on these instruments.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument that measures the difference in pressure between two points in a system. It is a vital tool in industries such as chemical processing, oil and gas, pharmaceuticals, and water treatment, where maintaining precise pressure levels is key to operational integrity. Swagelok's gauges are designed for durability and accuracy, often equipped with features that enhance their performance in demanding environments.

Pricing Factors for Swagelok Differential Pressure Gauges

1. Model Specifications Different models come with unique features tailored for specific applications. For instance, gauges designed for high-temperature or high-pressure environments typically cost more due to the materials and technology used in their construction. Standard models may be more affordable, but they might not withstand extreme conditions.

2. Material Quality The materials used in the gauge construction significantly impact pricing. Swagelok products are known for their high-quality stainless steel housings and other durable materials, which ensure longevity and reliability. Higher-quality materials generally lead to higher prices, but they also enhance performance and reduce maintenance costs over time.

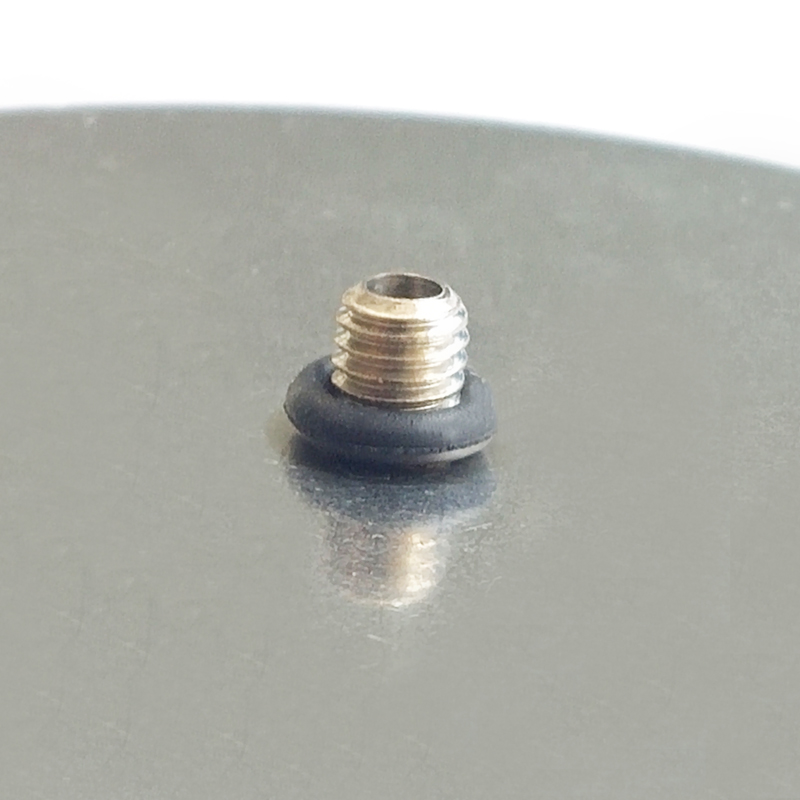

swagelok differential pressure gauge pricelist

3. Accuracy and Calibration Precision is paramount in differential pressure measurement. Gauges that offer higher accuracy ratings or come calibrated to specific standards may have a premium price tag. This is particularly relevant in industries where regulatory compliance is essential, as accurate measurements can prevent costly mistakes and ensure adherence to safety standards.

4. Additional Features Many Swagelok gauges come with enhanced features, such as digital readouts, data logging capabilities, and remote monitoring options. These advanced functionalities can increase the overall price of the gauge but may provide significant benefits, such as improved ease of use and greater data accuracy.

5. Quantity and Bulk Pricing Purchasing in bulk often leads to discounted pricing. Companies looking to equip entire facilities with differential pressure gauges may find significant savings by ordering larger quantities. Swagelok distributors may offer tiered pricing structures based on order volume, making it financially advantageous for larger projects.

6. Service and Support The level of customer support and service provided by the manufacturer or distributor can influence pricing. Swagelok is known for its comprehensive customer service, including installation support and maintenance advice. This added value can make a higher-priced product more attractive compared to a lower-priced alternative that lacks support.

Conclusion

When evaluating the pricing of Swagelok differential pressure gauges, it's important to consider a variety of factors beyond the initial cost. The investment in a quality differential pressure gauge is not purely a financial decision; it encompasses considerations of reliability, accuracy, and longevity. By understanding the factors that influence pricing, businesses can make informed decisions that align with their operational needs and budget constraints.

In summary, while Swagelok differential pressure gauges may present a higher initial investment, their quality, durability, and performance often justify the cost. As industrial demands evolve, ensuring that process measurement instruments meet both current and future requirements will remain a critical component of successful operations.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025