Nov . 04, 2024 18:11 Back to list

static pressure in differential pressure gauge exporter

Understanding Static Pressure in Differential Pressure Gauges

Differential pressure gauges are essential instruments used across various industries to measure the difference in pressure between two points. One of the most critical aspects of these gauges is their ability to provide accurate readings of static pressure, which can greatly influence the effectiveness of processes in fluid systems. This article explores the significance of static pressure in differential pressure gauges, and its applications in industrial contexts.

Static pressure refers to the pressure exerted by a fluid at rest. In a differential pressure gauge, static pressure is a critical component, as it can affect the accuracy and reliability of the readings. For instance, the gauge typically measures the pressure difference between two points in a system—often referred to as the high-pressure side and the low-pressure side. However, the static pressure in each of these points can introduce variables that might skew the data if not properly accounted for.

In practical applications, static pressure is essential for understanding system performance. For example, in HVAC systems, accurate measurements of static pressure can help maintain optimal airflow, ensuring efficiency and comfort. Any fluctuations in static pressure can lead to imbalances, resulting in energy inefficiencies and increased operational costs. Therefore, knowing how to interpret static pressure data from differential gauges is crucial for engineers and technicians working in this field.

static pressure in differential pressure gauge exporter

Another key application of static pressure measurements is in the monitoring of filtration systems. In these systems, differential pressure gauges help determine the cleanliness of filters by measuring the pressure before and after the filter medium. A significant increase in static pressure difference may indicate that the filter is becoming clogged, prompting maintenance or replacement to ensure continued system performance.

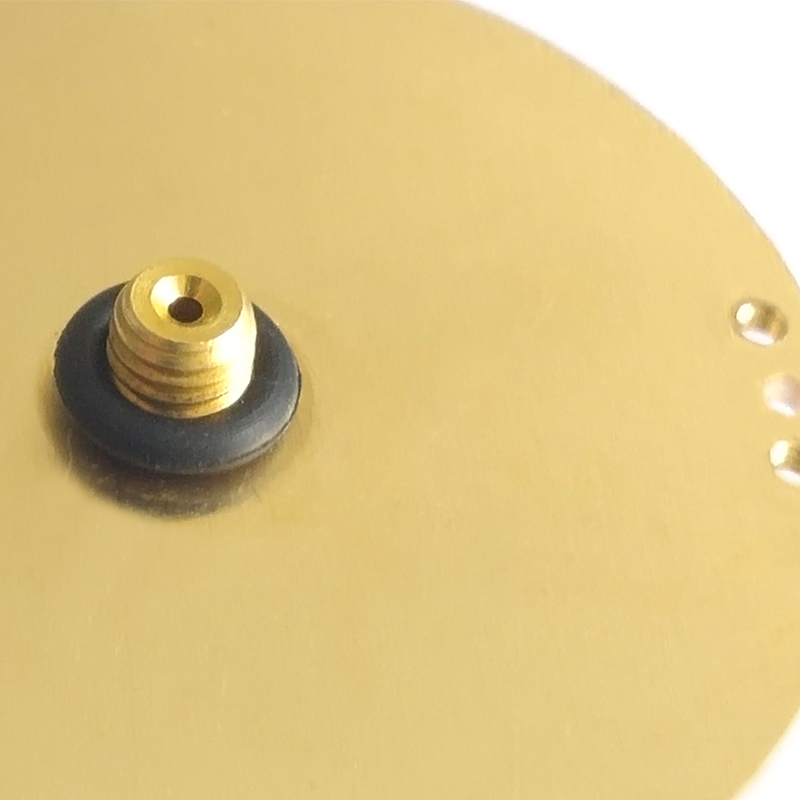

The construction and calibration of differential pressure gauges are designed to take static pressure into account. Manufacturers often provide specifications that outline the gauge's performance characteristics under varying static pressure conditions. Therefore, selecting the right gauge for specific applications requires an understanding of both the static pressure and the expected differential pressure ranges.

Furthermore, advancements in technology are leading to the development of more sophisticated differential pressure gauges that integrate digital displays and data logging. This allows for better visualization and tracking of static pressure trends over time, making it easier for operators to identify anomalies and react promptly.

In conclusion, static pressure is a vital factor in the functionality and accuracy of differential pressure gauges. Understanding how it influences measurement and system performance is essential for optimizing processes across various industrial applications. By leveraging accurate static pressure readings, businesses can improve efficiency, enhance safety, and reduce costs in their operations.

-

High-Precision Mass Diaphragm Pressure Gauge - Reliable & Durable Solutions

NewsJun.10,2025

-

Explain Diaphragm Pressure Gauge Expert Guide, Top Manufacturers & Quotes

NewsJun.10,2025

-

Affordable Differential Pressure Gauge Prices in China Top Manufacturers

NewsJun.10,2025

-

Reliable Water Fire Extinguisher Pressure Gauges for Safety

NewsJun.10,2025

-

Durable Diaphragm Protection Pressure Gauges Get Quote

NewsJun.09,2025

-

WIKA Differential Pressure Gauge with Switch Reliable Monitoring & Control

NewsJun.09,2025